Ultrasound main shaft cutting state monitoring system and method

A condition monitoring system, ultrasonic cutting technology, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problem of less reliability research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below.

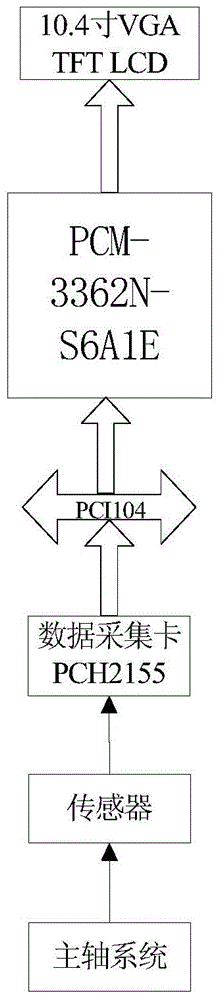

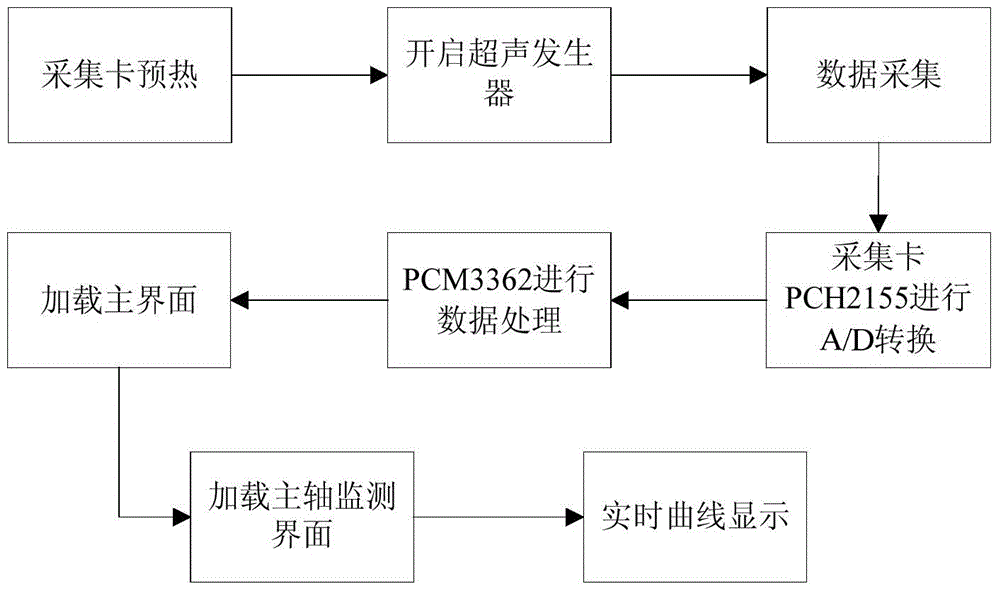

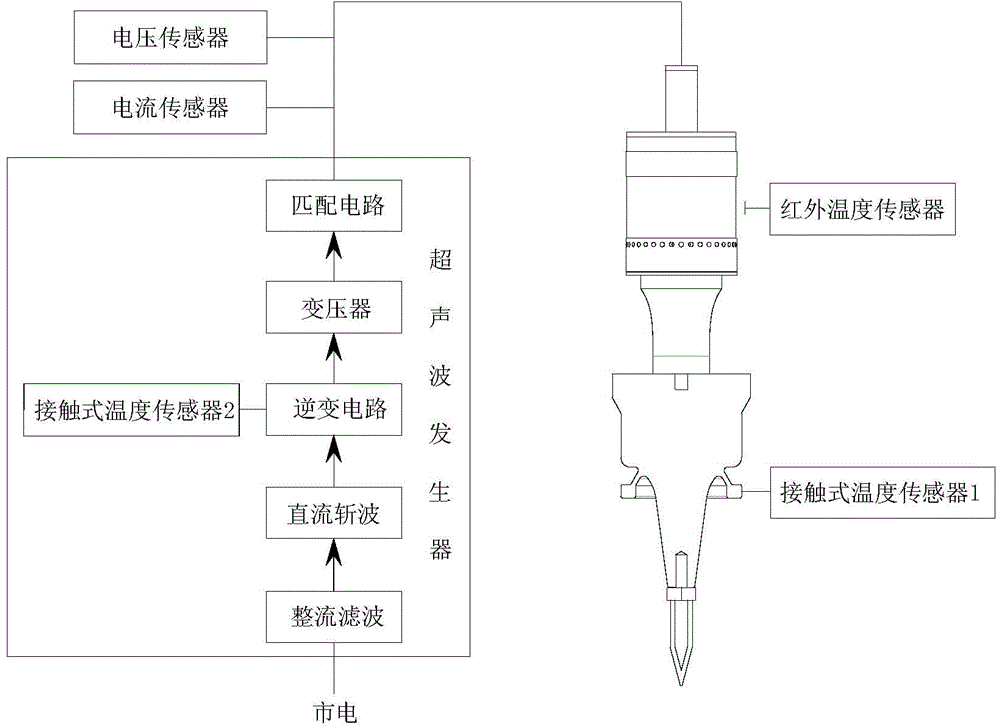

[0045] like figure 1 As shown, an ultrasonic cutting spindle status monitoring system includes PCM-3362N-S6A1E motherboard, PCH2155 data acquisition card, 10.4SVGA TFT LCD display and sensors. The motherboard and the PCH2155 data acquisition card are connected through the PCI104 bus, that is, through the 120-pin 2mm hole stack socket, and the 10.4SVGA TFT LCD display driver unit is connected to the main board through the VGA interface to drive the touch screen. Mutual switching, threshold parameter setting and dynamic curve display. The sensor and the acquisition card are connected with DuPont lines. The sensor collects the voltage, current, and temperature signals of the spindle system, and performs A / D conversion through the data acquisition card. The interface transmits the data to the 10.4-inch displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com