Automatic hairline processing device and hairline processing method thereof

A hairline machine and hairline technology, which are applied to surface polishing machine tools, machine tools suitable for grinding workpiece planes, grinding machines, etc., can solve the problems of high labor intensity, low manual operation efficiency, and easy operator fatigue, etc. The effect of reducing labor intensity, improving work efficiency and hairline quality, and reducing strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

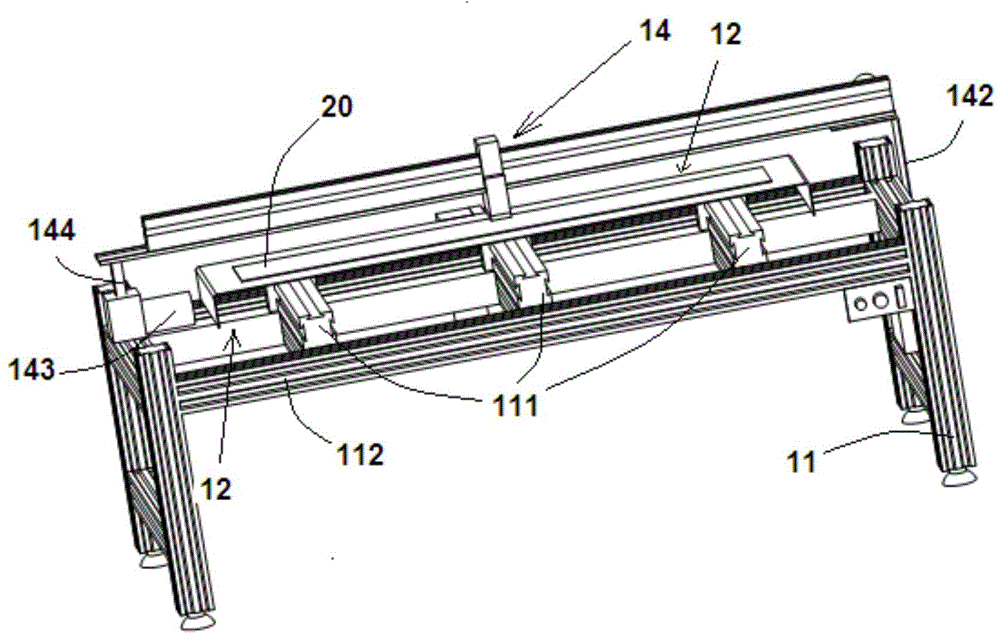

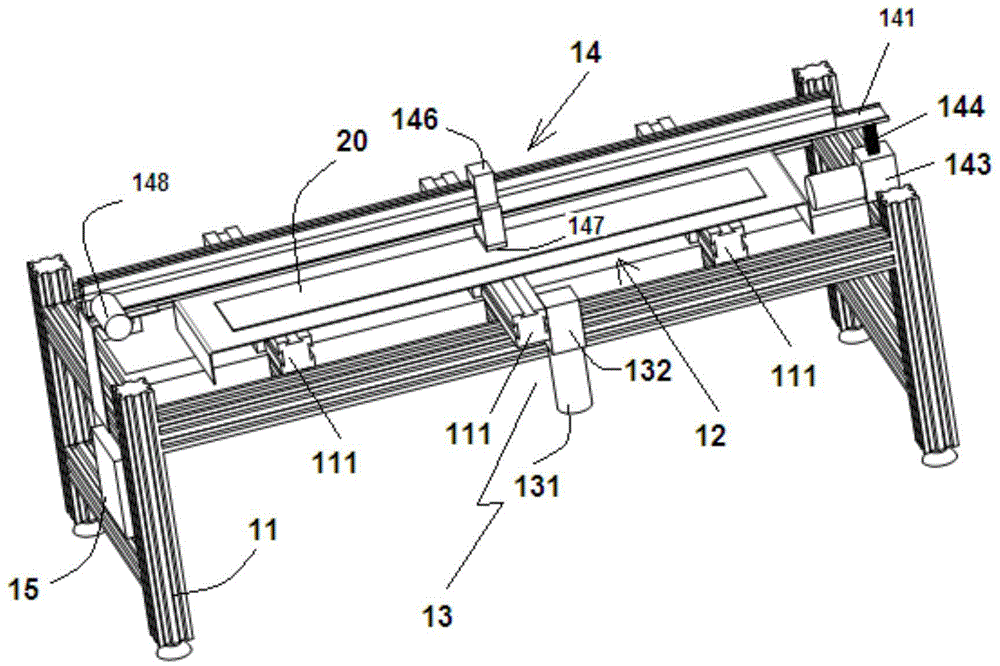

[0043] see figure 1 , figure 2 An automatic hairline machine shown includes:

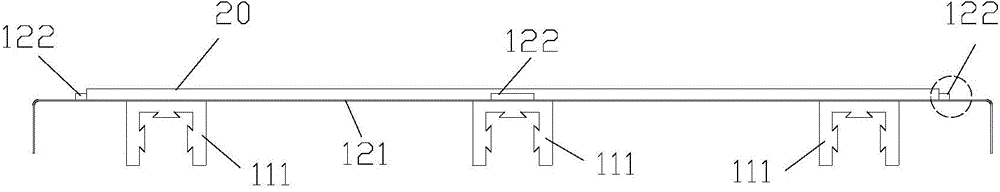

[0044] Frame 11, the upper plane of the frame 11 in cuboid structure is provided with 3 platen guide rails 111 parallel to each other and evenly spaced;

[0045] Platen 12, platen comprises square flat plate 121 and stopper 122, and stopper 122 is respectively arranged on the top four sides of flat plate 121 and is fixedly connected with flat plate; The height of stopper 122 is lower than the height of workpiece 20 to be processed; 12 is arranged above the platen guide rail 111, and the platen is perpendicular to the platen guide rail; the shape of the cavity formed by the flat plate and the stopper matches the shape of the workpiece 20 to be processed; for details, see image 3 , Figure 4 , Figure 5 shown.

[0046] The platen horizontal movement mechanism 13, the platen horizontal movement mechanism 13 is arranged under the platen 12 and is connected and fixed with the platen;

[0047] A h...

Embodiment 2

[0061] An automatic hairline method, the concrete steps of the automatic hairline method are:

[0062] A. The controller controls the hairline mechanism to lift up;

[0063] B. The horizontal moving mechanism of the console board of the controller moves the initial processing position of the workpiece placed on the table horizontally to the bottom of the hairline mechanism;

[0064] C. The controller controls the hairline mechanism to move down to the position where the hairline mechanism can perform hairline on the workpiece to be processed;

[0065] D. The controller controls the hairline mechanism to reciprocate horizontally on the workpiece to be processed. The length of the hairline and the reciprocating times of the hairline follow the length value preset in the controller and the reciprocating times of the hairline preset in the controller. ;

[0066] E. After the controller controls the hairline mechanism to lift up, the controller moves forward the horizontal moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com