Offline bridge crane locus control method

An overhead crane and trajectory control technology, applied in the direction of load hanging components, transportation and packaging, can solve the problem of unable to guarantee the important constraints of the crane system, and achieve the effect of simple and practical trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0109] Further illustrate the present invention below in conjunction with accompanying drawing.

[0110] The constrained underactuated overhead traveling crane acceleration trajectory control method provided by the present invention comprises the following steps:

[0111] 1. Description of experimental steps

[0112] Step 1. Trajectory planning scheme

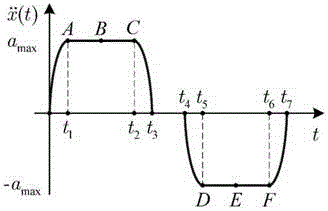

[0113] For traditional bridge cranes, a three-stage acceleration (uniform acceleration-uniform speed-uniform deceleration) trajectory is generally used for transportation, that is, the attached figure 2 shown. However, the discontinuity of acceleration may cause certain damage to the crane equipment; moreover, in the actual application process, it is challenging to strictly follow the three-stage acceleration trajectory. Therefore, the present invention proposes a kind of smooth acceleration trajectory, and its expression is as follows:

[0114]

[0115] Among them, a max is the maximum acceleration used in the actual t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com