Double-frequency liquid crystal material having low critical frequency

A dual-frequency liquid crystal, low critical technology, applied in the direction of liquid crystal materials, instruments, chemical instruments and methods, etc., can solve the problems of dielectric loss, affecting the service life of liquid crystal devices, and unfavorable dual-frequency liquid crystals for portable devices. Effect of working voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

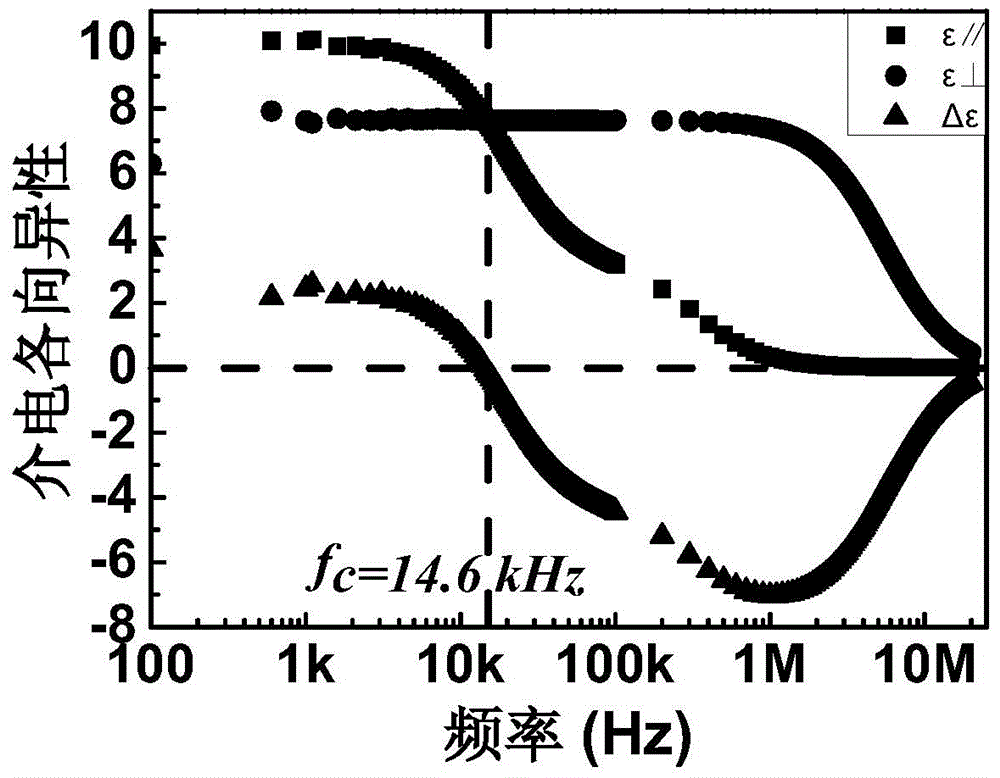

Embodiment 1

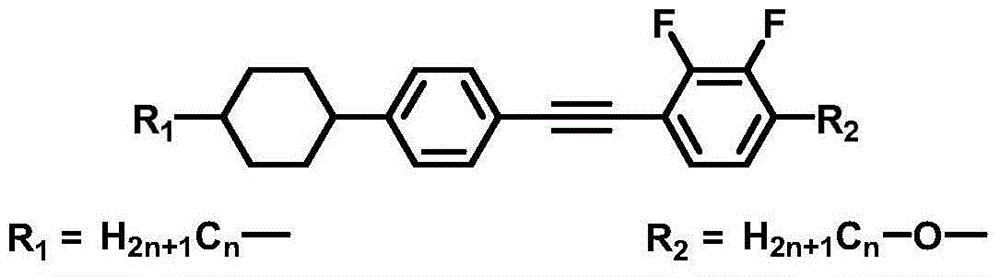

[0039] The dual-frequency liquid crystal material consists of 21.63% component A (A-1: R 1 =C 3 h 7 , R 2 =OC 2 h 5 12.38%; A-2: R 1 =C 3 h 7 , R2 =OCH 3 9.25%), 21.78% of component B (B-1: R 1 =C 3 h 7 , R 2 =OC 2 h 5 8.52%; B-2: R 1 =C 3 h 7 , R 2 =OCH 3 9.38%; B-3: R 1 =C 4 h 9 , R 2 =OCH 3 3.88%), 19.84% of component C (C-1: R 1 =C 3 h 7 , R 2 =OCH 3 12.01%; C-2: R 1 =C 3 h 7 , R 2 =OC 2 h 5 accounted for 7.83%), 9.42% of component D (D-1: R 1 =C 4 h 9 , R 2 =OC 2 h 5 4.85%; D-2: R 1 =C 5 h 11 , R 2 =OC 2 h 5 Accounting for 4.57%), 11.45% of component E (E: R 1 =C 5 h 11 accounted for 11.45%), 8.38% of component F (F-1: R 1 =C 3 h 7 4.26%; F-2: R 1 =C 5 h 11 4.12%), 7.50% of component G (G-1: R 1 =C 3 h 7 3.55%; G-2: R 1 =C 5 h 11 Accounting for 3.95%) formed by melt mixing. The molecular structure formula and ratio of each component compound are shown in Table 1 below.

[0040] Table 1 Molecular structural form...

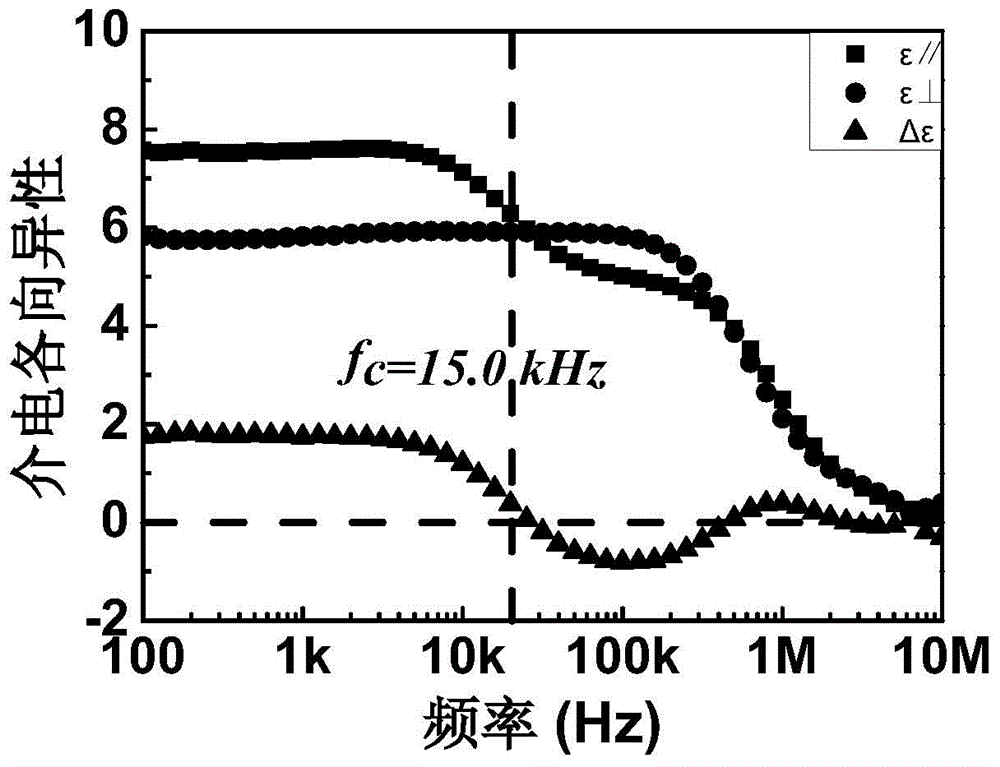

Embodiment 2

[0046] The dual-frequency liquid crystal material consists of 21.80% component A (A-1: R 1 =C 3 h 7 , R 2 =OC 2 h 5 11.55%; A-2: R 1 =C 3 h 7 , R 2 =OCH 3 accounted for 10.25%), 20.52% of component B (B-1: R 1 =C 3 h 7 , R 2 =OC 2 h 5 10.43%; B-2: R 1 =C 3 h 7 , R 2 =OCH 3 accounted for 10.09%), 23.36% of component C (C-1: R 1 =C 3 h 7 , R 2 =OCH 3 13.54%; C-2: R 1 =C 3 h 7 , R 2 =OC 2 h 5 9.82%), 11.46% of component D (D-1: R 1 =C 3 h 7 , R 2 =OC 2 h 5 5.34%; D-2: R 1 =C 5 h 11 , R 2 =OC 2 h 5 accounted for 6.12%), 11.36% of component E (E-1: R 1 =C 5 h 11 5.88%, E-2: R 1 =C 3 h 7 accounted for 5.48%), 6.37% of component F (F-1: R 1 =C 3 h 7 3.15%; F-2: R 1 =C 5 h 11 accounted for 3.22%), 5.13% of component G (G-1: R 1 =C 3 h 7 2.17%; G-2: R 1 =C 5 h 11 Accounting for 2.96%) formed by melt mixing. The molecular structure formula and ratio of each component compound are shown in Table 2 below.

[0047] Table 2 Molecu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystallization point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Crystallization point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com