Automatic double-width cloth shearing device of air-jet loom

An air-jet loom and web technology, which is used in auxiliary equipment for weaving, textile, textile and paper making, etc., can solve the problems of unguaranteed product quality, high cost of device accessories, unstable working performance, etc., and achieves simple structure and processing. Low cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

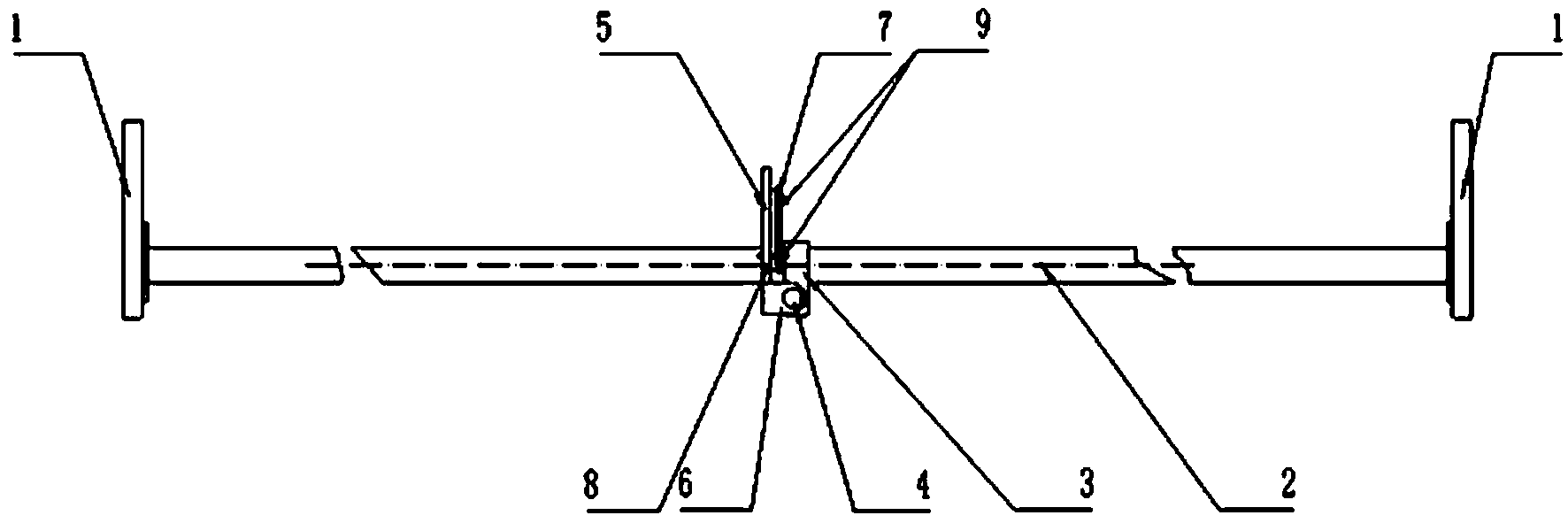

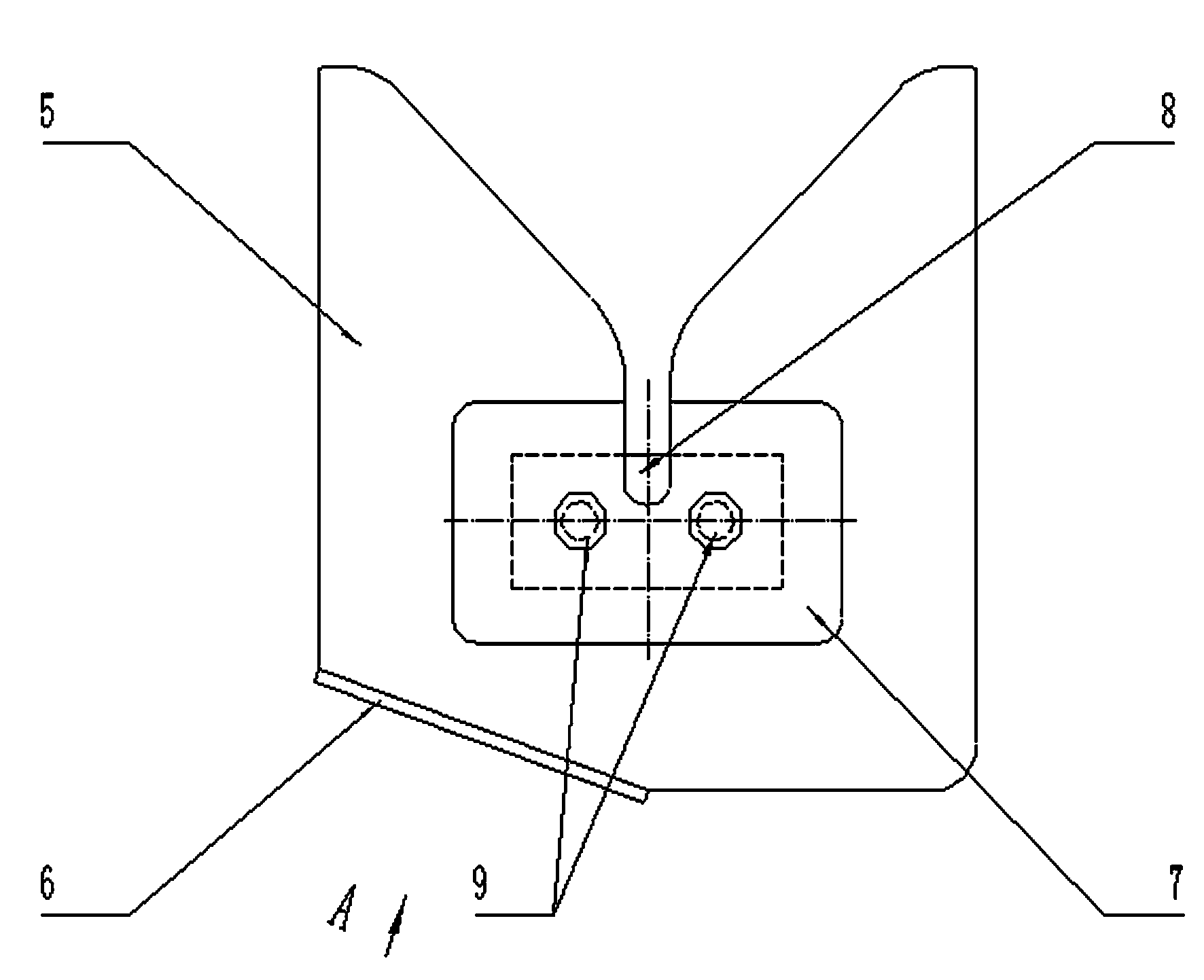

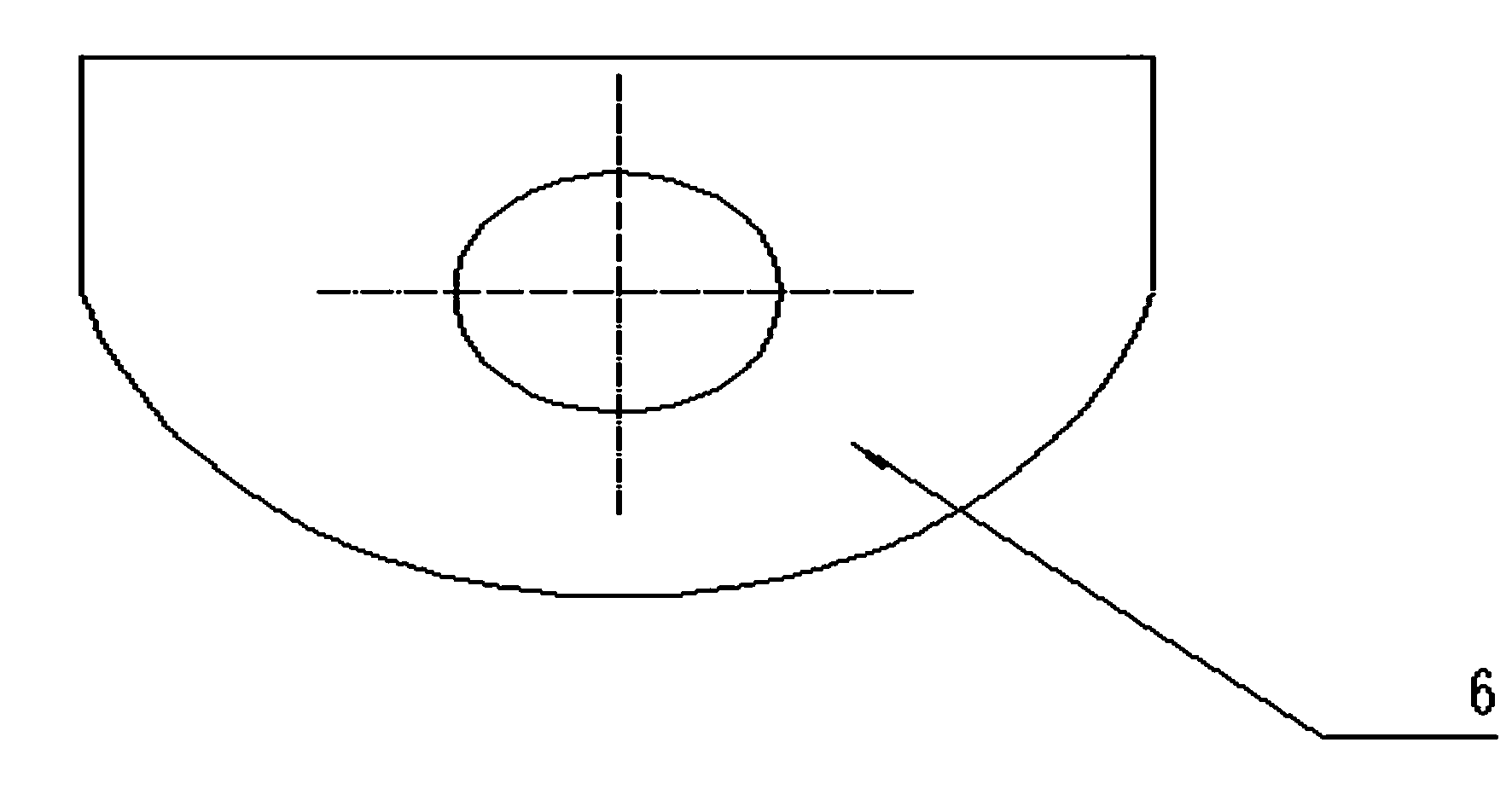

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the double-width cloth automatic cutting device of the air-jet loom of the present invention includes relatively fixed base plates 1, and positioning rods 2 are arranged between the fixed base boards 1, and the positioning rods 2 are provided with clamping rings 3; One side of the clamping ring 3 is provided with a "V"-shaped guide plate 5, and the "V"-shaped guide plate 5 is provided with a side hanging ear 6, and the side hanging ear 6 is movably connected with the clamping ring 3 through the first bolt 4; The "V" shaped guide plate 5 is provided with a "V" shaped guide plate guide groove 10; one side of the "V" shaped guide plate 5 is provided with a splint 7, and the splint 7 is provided with a corresponding Plywood guide groove 11; a blade 8 is provided between the "V"-shaped guide pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com