Electro-osmotic drainage consolidation method for electrode pipes

A technology of drainage consolidation and electrode tube, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of difficulty in guaranteeing the efficiency and effect of electroosmosis, lack of it, and inability to give full play to the advantages of electroosmosis, so as to achieve targeted Strong, improve efficiency, guarantee speed and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Such as figure 1 As shown, the drainage area 1 is circular, and the plastic electrode tubes are evenly arranged in squares. The outermost layer 2 electrodes are negatively charged, and the boundary layer 3 is positively charged. The distance between the outermost layer 2 and the boundary layer 3 electrodes is 0.5m. The spacing is 1m, and the power supply adopts the steady flow mode with a current of 300A. All positive electrodes and negative electrodes in the boundary layer 3 are collected and connected to a voltmeter.

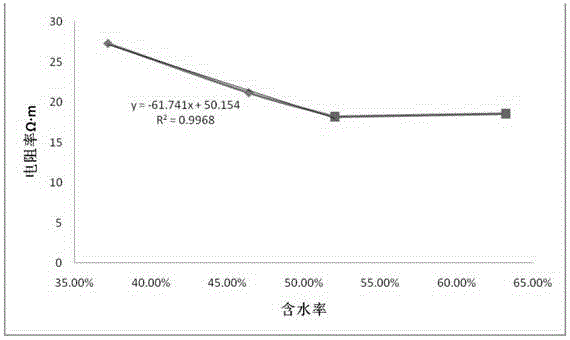

[0040] Use the test device Miller Soil Box to measure the soil resistivity and draw the curve, such as Figure 4 As shown, the moisture content is set to 52%;

[0041] Electrode electrification: Start the vacuum pump to discharge some free water in the soil. After the vacuum is stable, start the DC power supply to electrify the electrode. The electrode electrification method is:

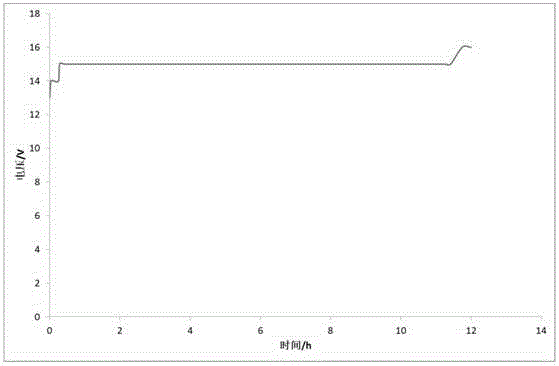

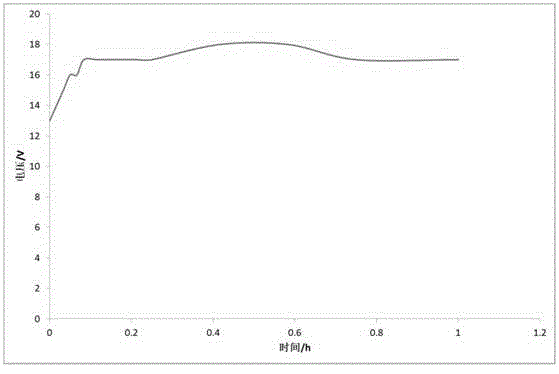

[0042] (1) Reversing power supply at intervals: connect the inner el...

Embodiment 2

[0048] Such as figure 1 As shown, the drainage area 1 is circular, and the plastic electrode tubes are evenly arranged in squares. The outermost electrode 2 is negatively charged, and the boundary layer 3 is positively charged. The distance between the outermost layer and the boundary layer electrodes is 0.75m. Negative and positive alternating currents are used in sequence, and the electrode spacing in the boundary layer 3 area is 1m. The power supply adopts a regulated power-on mode with a voltage of 80V. All the positive electrodes and negative electrodes in the boundary layer 3 are connected to the ammeter after being collected respectively.

[0049] Use the test device Miller Soil Box to measure the soil resistivity and draw the curve, such as Figure 4 As shown, the moisture content is set to 52%;

[0050] Electrode electrification: Start the vacuum pump to discharge some free water in the soil. After the vacuum is stable, start the DC power supply to electrify the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com