Three-phase power rectification LC high-PF filtering direct-current high-voltage direct-drive LED circuit

An LED circuit, DC high voltage technology, applied in the field of electronics, can solve the problems of not meeting the index requirements of high-power LED lamps, reducing the power factor of the driving power supply, etc., achieving good social and economic benefits, improving luminous efficiency, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

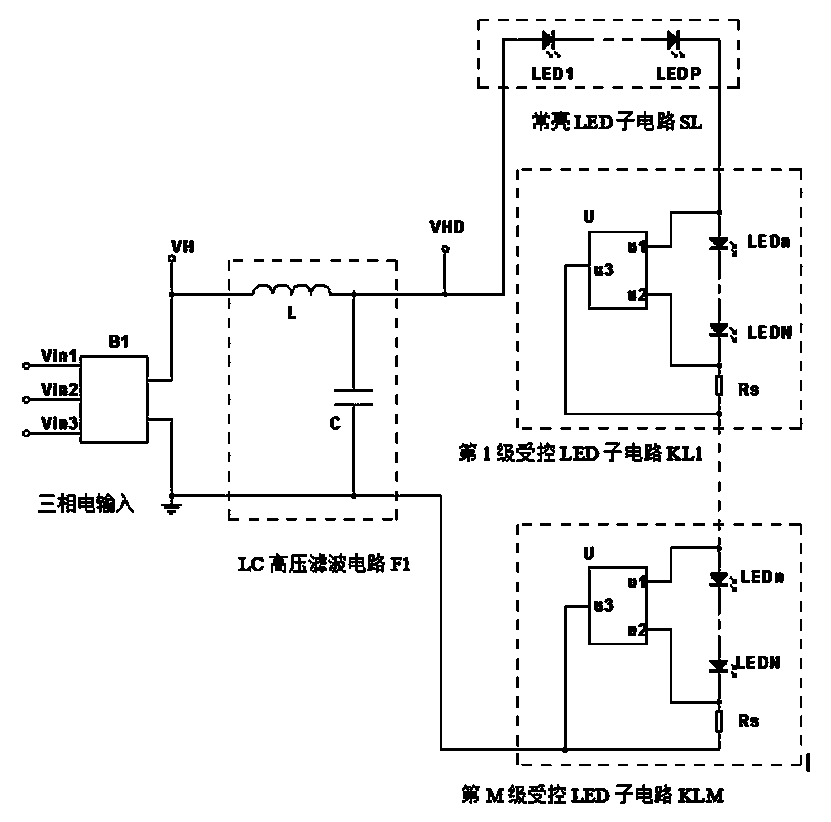

[0029] Such as figure 1 As shown, a three-phase electric rectification LC high PF filter DC high-voltage direct drive LED circuit, including a three-phase full-wave rectifier, an LC high-voltage filter circuit, a constant bright LED sub-circuit and a controlled LED circuit; wherein,

[0030] The three-phase full-wave rectifier B1 includes three three-phase AC input terminals Vin1, Vin2, Vin3, a rectified high voltage output terminal VH and a reference ground terminal GND.

[0031] This embodiment provides an LC high-voltage filter circuit F1, which includes an inductor L and a high-voltage capacitor C. Among them, the inductor L and the capacitor C are connected in series, one end of the inductor L is connected to the rectified high-voltage output terminal VH, one end of the capacitor C is connected to the reference ground GND, and the common terminal of the inductor L and the high-voltage capacitor C is the DC high-voltage output terminal of the LC high-voltage filter circuit...

Embodiment 2

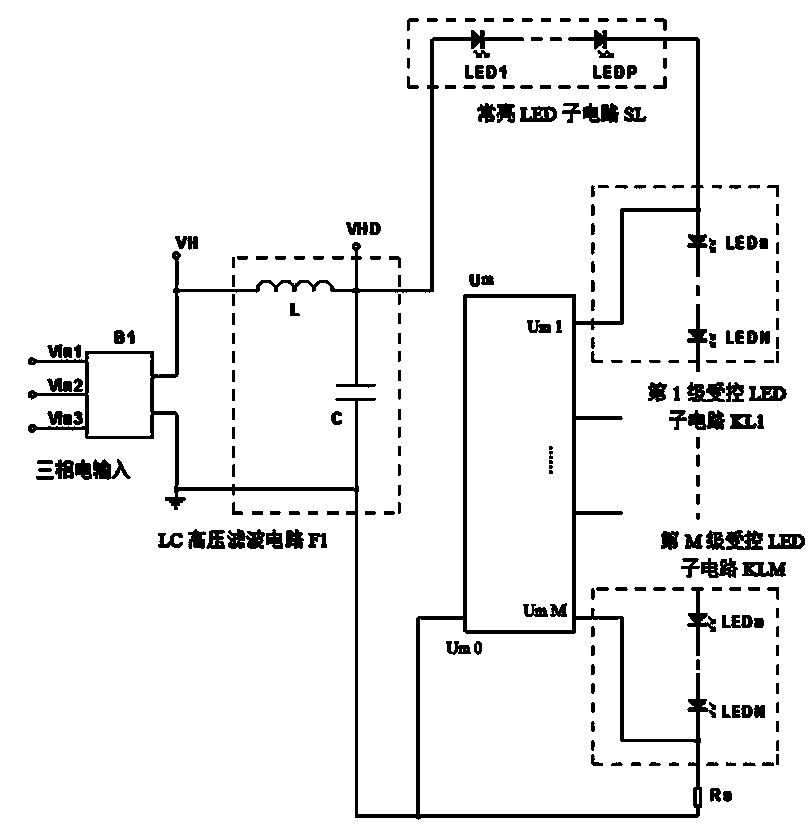

[0037] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 lies in that the structure of the controlled LED circuit is different.

[0038] In this embodiment, the controlled LED circuit also includes a multi-level control multi-output direct drive LED integrated circuit Um and a current sampling resistor Rs; the multi-level control multi-output direct drive LED integrated circuit Um is provided with multiple control terminals (Um 1 -Um M) and a direct-drive LED integrated circuit with a zero-potential reference terminal Um 0; among them, the controlled LED sub-circuit (KL 1-KL M) includes LED groups, and the LED groups include several LEDs in series in the same direction (LED n- LED N); the current inflow end of one LED group is connected to a control end of the second direct drive LED integrated circuit Um, one end of the current sampling resistor Rs is connected to the current outflow end of the last stage controlled LED sub-circuit KL M, and ...

Embodiment 3

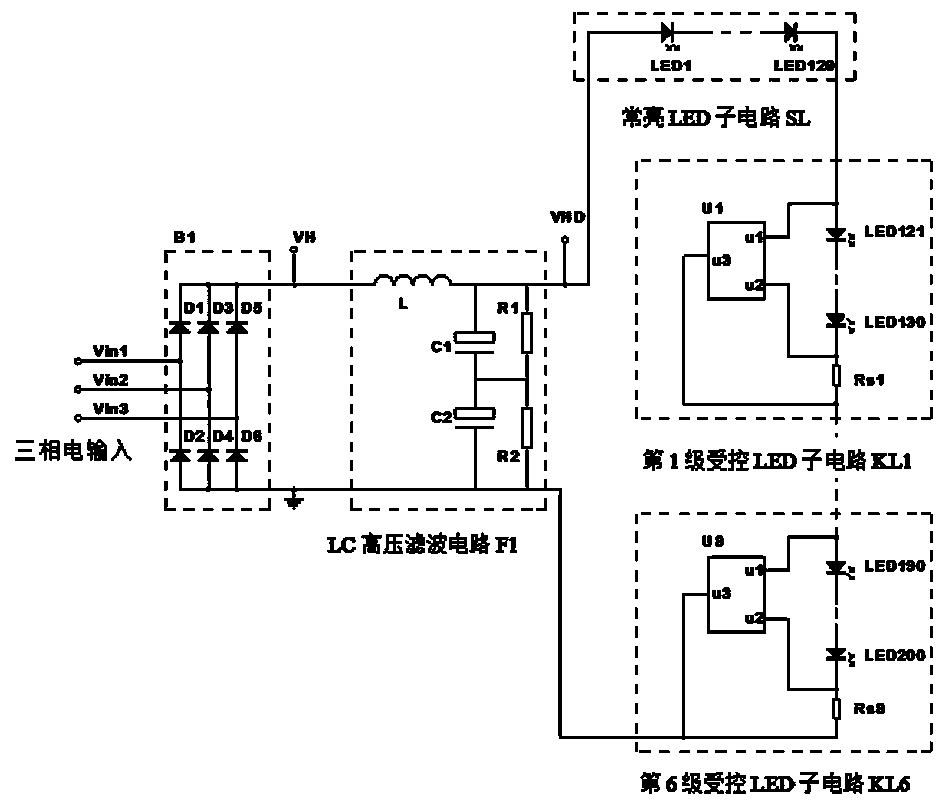

[0042] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that a specific circuit structure of a rectified LC high PF filtered DC high voltage direct drive LED circuit suitable for 120W three-phase power is provided.

[0043] This implementation provides another LC high-voltage filter circuit F1, which includes an inductor L, a first high-voltage electrolytic capacitor C1, a second high-voltage electrolytic capacitor C2, a first discharge resistor R1, and a second discharge resistor R2. One end of the inductor L is connected to the rectified high-voltage The output terminal VH and the other end of the inductor L are respectively connected to the positive pole of the first high-voltage electrolytic capacitor C1 and one end of the first discharge resistor R1, and the negative pole of the first high-voltage electrolytic capacitor C1 is respectively connected to the positive pole of the second high-voltage electrolytic capacitor C2 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com