Mechanical pencil

A technology for mechanical pencils and refills, applied to mechanical pencils, writing connectors, printing, etc., to achieve the effects of easy loading and operation, reduced number of parts, and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

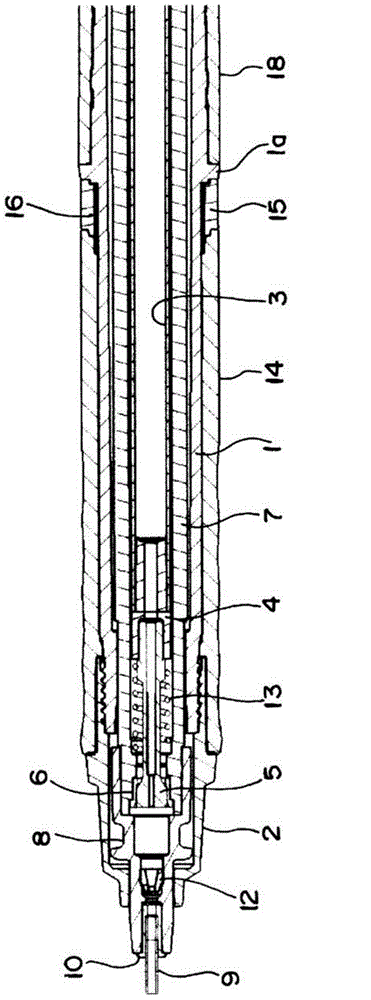

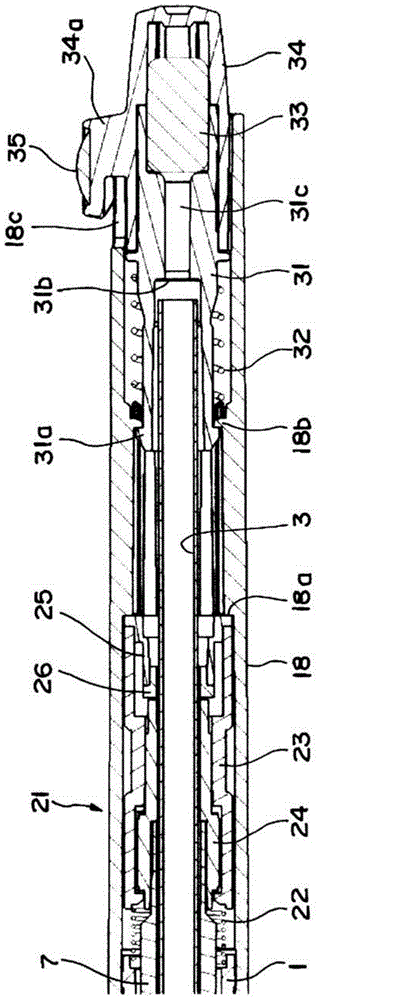

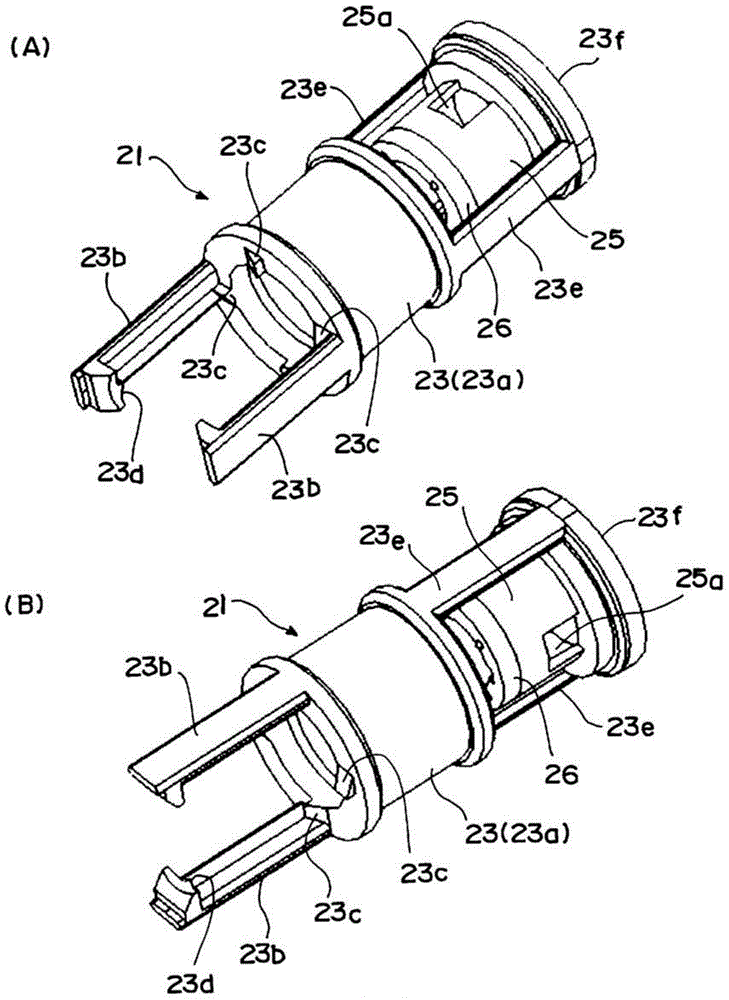

[0029] The mechanical pencil according to the present invention will be described based on an embodiment in which the lead is rotationally driven according to writing pressure. In addition, although the same parts are denoted by the same symbols in each of the drawings shown below, depending on the situation of the drawings, symbols may be attached to typical parts in some drawings, and the detailed structure The description will refer to symbols attached to other drawings.

[0030] figure 1 and figure 2 It is used to divide it into the first half and the second half to illustrate the overall structure of the mechanical pencil. First, in figure 1 Among them, on the front end portion of the front shaft 1 constituting the shaft cylinder, the front shaft 1 is detachably mounted through a threaded joint end member (mouth first member, base member) 2 . Then, a cylindrical core box 3 is accommodated along the axial cores of the above-mentioned front axle 1 and the following rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com