A fully fed rapeseed combine harvester

A combine harvester and full-feeding technology, which is applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of high stubble cutting, poor harvesting effect, and low cleaning rate, so as to facilitate cleaning and recycling Simple cultivation, structure and operation, and the effect of strengthening the threshing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

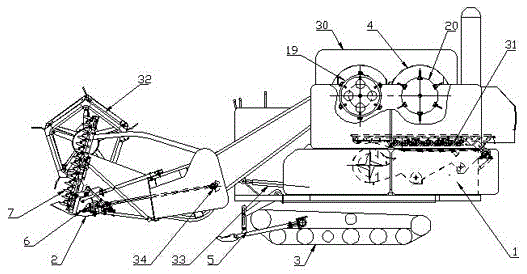

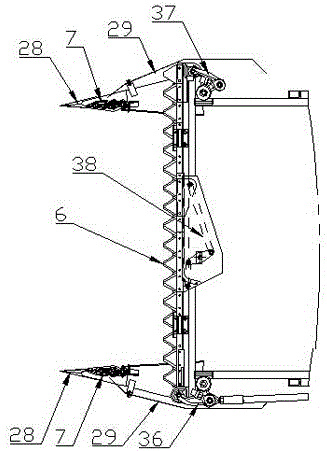

[0031] See details Figure 1 to Figure 5 , a full-feeding rapeseed combine harvester, including a body 1, a grain storage box 30, a power system, a header 2 mounted on the front end of the body 1, and a walking device 3 arranged under the body 1, which also includes a The threshing device 4 above the body 1 and the residue processing device 5 located at the front of the body 1, the screening device 31 is set at the bottom of the threshing device 4, and the rolling device 32 (that is, the reel) is set above the header 2, The header 2 is arranged on the front end of the machine body 1, and includes a group of double-action transverse cutters 6 and vertical cutters 7 on both sides; wherein, the double-action transverse cutter 6 is located below the front end of the header 2 for cutting Compared with the horizontal cutting knife in the prior art, the rape stalk not only enhances the shearing effect on the rape stalk, but also can adapt to the thick rape stalk. After the rape is cu...

Embodiment 2

[0035] See details figure 1and Figure 4 As an improvement of the above-mentioned first embodiment, the stubble processing device 5 includes a lifting device connected to the header 2, a support arm 8 driven by the lifting device and moving synchronously with it, and the stubble processing device 5 mainly uses Cut the stubble left after the rape stalks are cut by the cutting table 2, wherein the support arms 8 are located on both sides of the body 1, the front end is provided with a cutting knife 9, and the rear ends are connected to the body through the main support shaft 18. 1 connection; the lifting device includes three lugs 10, two connecting rods 11 with elongated holes 14, a pull rod 12 and a steel rope 13, wherein the three lugs 10 are respectively connected to the header 2 and the machine body 1 On the knife rest 55 of the cutting knife 9, one end of the two connecting rods 11 is connected with the lug 10 on the knife rest 55 respectively, and the two long holes 14 a...

Embodiment 3

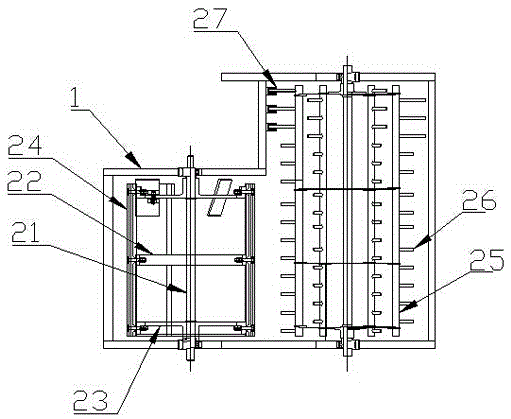

[0039] See details figure 1 and image 3 , the threshing device 4 in this embodiment includes a primary threshing roller 19 and a secondary threshing roller 20 located in the machine body 1, wherein the primary threshing roller 19 includes a threshing roller shaft 21, a connecting ring 22 and a threshing hub 23. Skeleton, and the grain bar 24 that is connected on this framework, the primary threshing roller 19 of grain bar structure can strengthen the rape threshing effect of the first stage, and reduce the crushing strength of the rape straw in the first stage threshing work, thereby alleviate The intensity of the later screening work reduces the load on the screen surface and prevents the screen surface from being blocked. At the same time, it enables the grass seeds to be separated quickly and fully in the second stage of threshing work, improving the threshing and separation capabilities of the entire harvester.

[0040] The secondary threshing roller 20 is arranged behin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com