Spoke casting mould

A technology for casting molds and molds, which is applied in the field of molds for casting spokes, can solve the problems of rapid temperature divergence, many sealing surfaces, and flashing edges, and achieves the effect of reducing the difficulty of cleaning work, reducing sealing surfaces, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

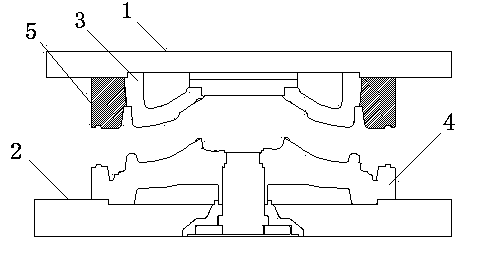

[0011] like figure 1 A kind of wheel spoke casting mold shown comprises the upper mold 3 that is connected to upper mold mounting plate 1 and the lower mold 4 that is connected to lower mold mounting plate 2, and described upper mold 3 outer periphery is provided with upper mold ring 5, and upper mold ring The inner wall of the upper mold ring 5 is matched with the outer wall size of the upper mold 3, and the two are closely matched. The upper end surface of the upper mold ring 5 is fixedly connected to the upper mold mounting plate 1, and the lower mold ring 5 and the upper mold 3 are combined. The end face matches the upper end face of the lower mold 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com