Protection film

A protective film, non-adhesive technology, applied in the direction of film/sheet-like adhesives, adhesives, etc., can solve the problems of two protective films 1 sticking to each other, melting, affecting the smooth production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

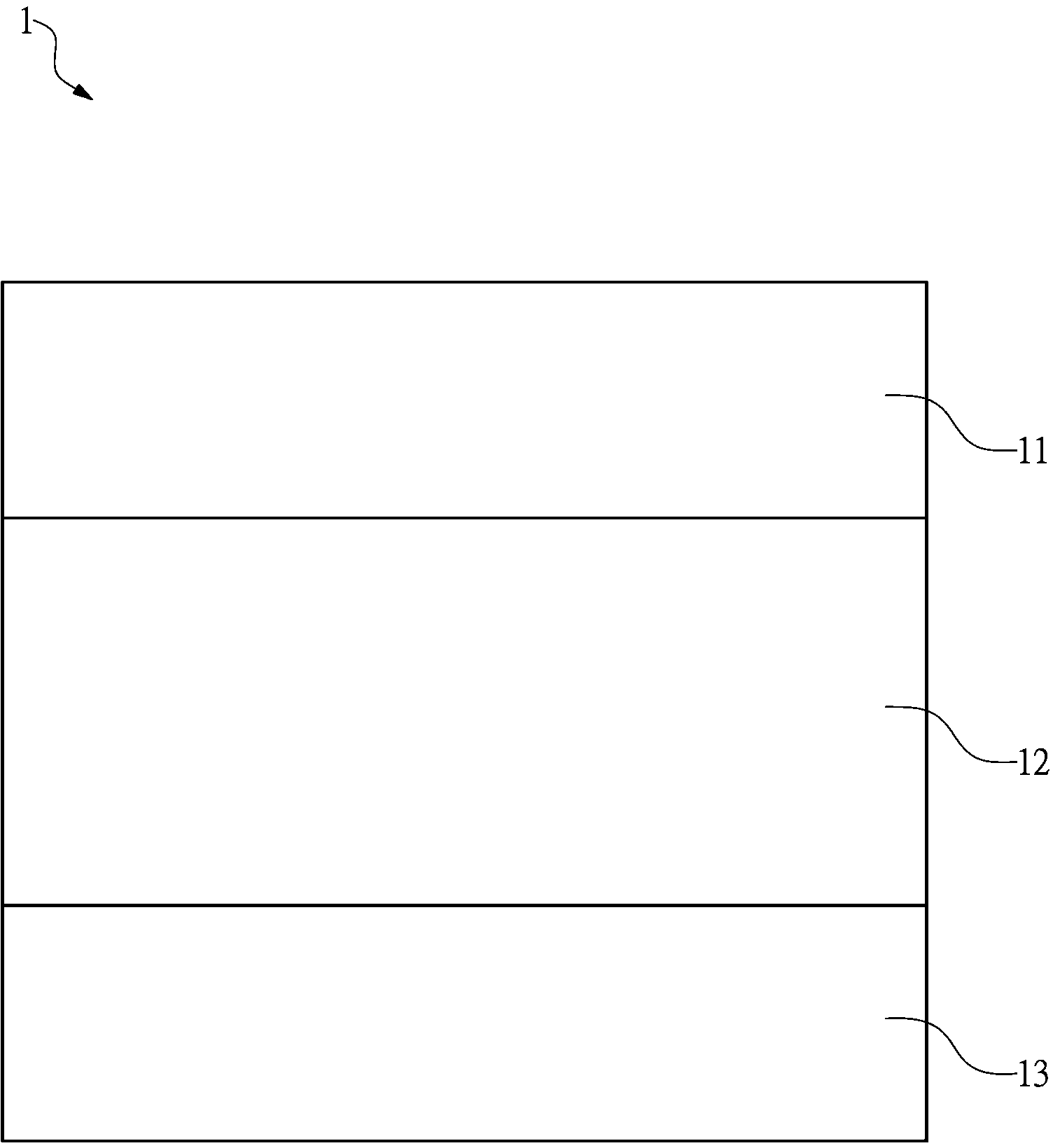

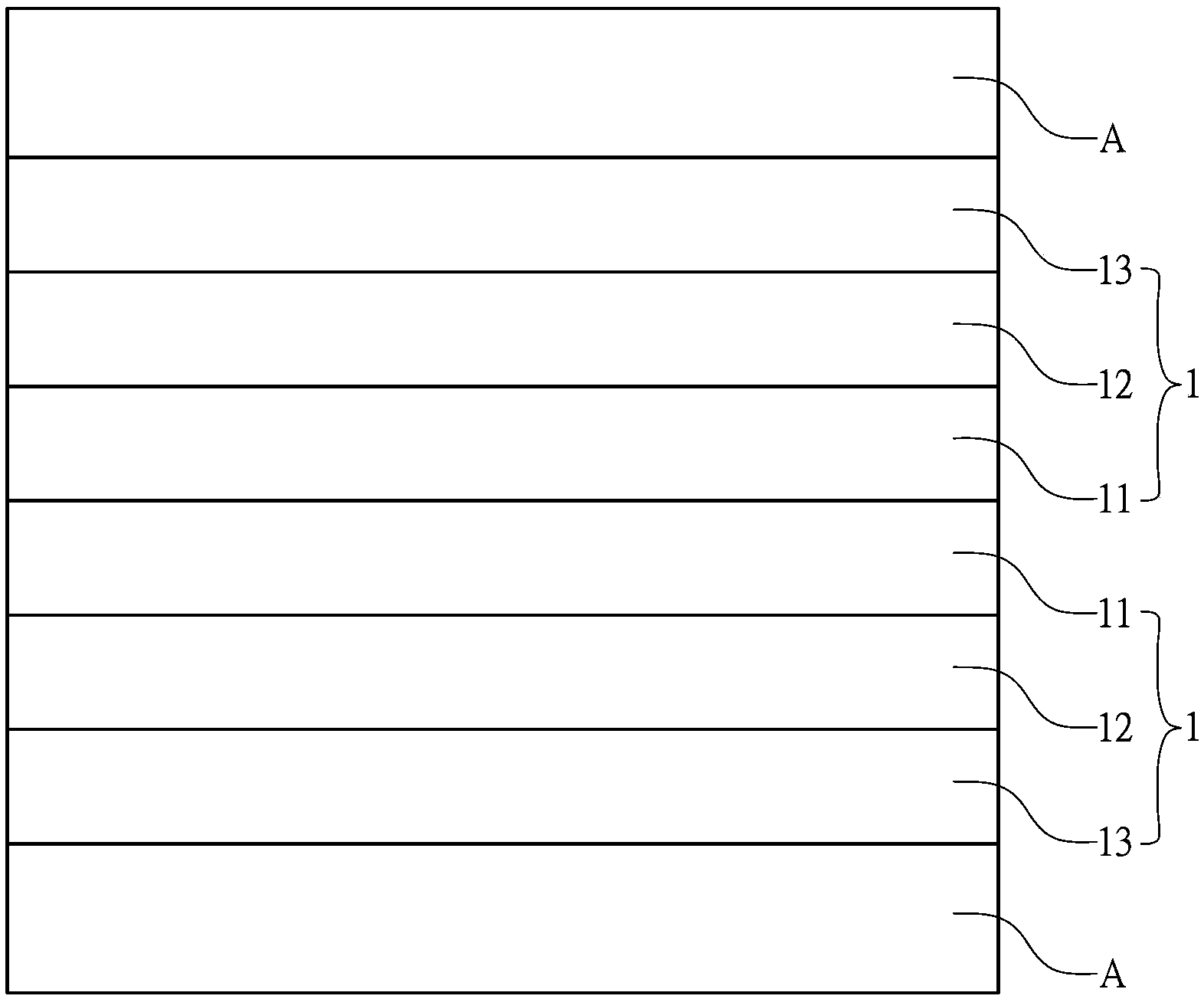

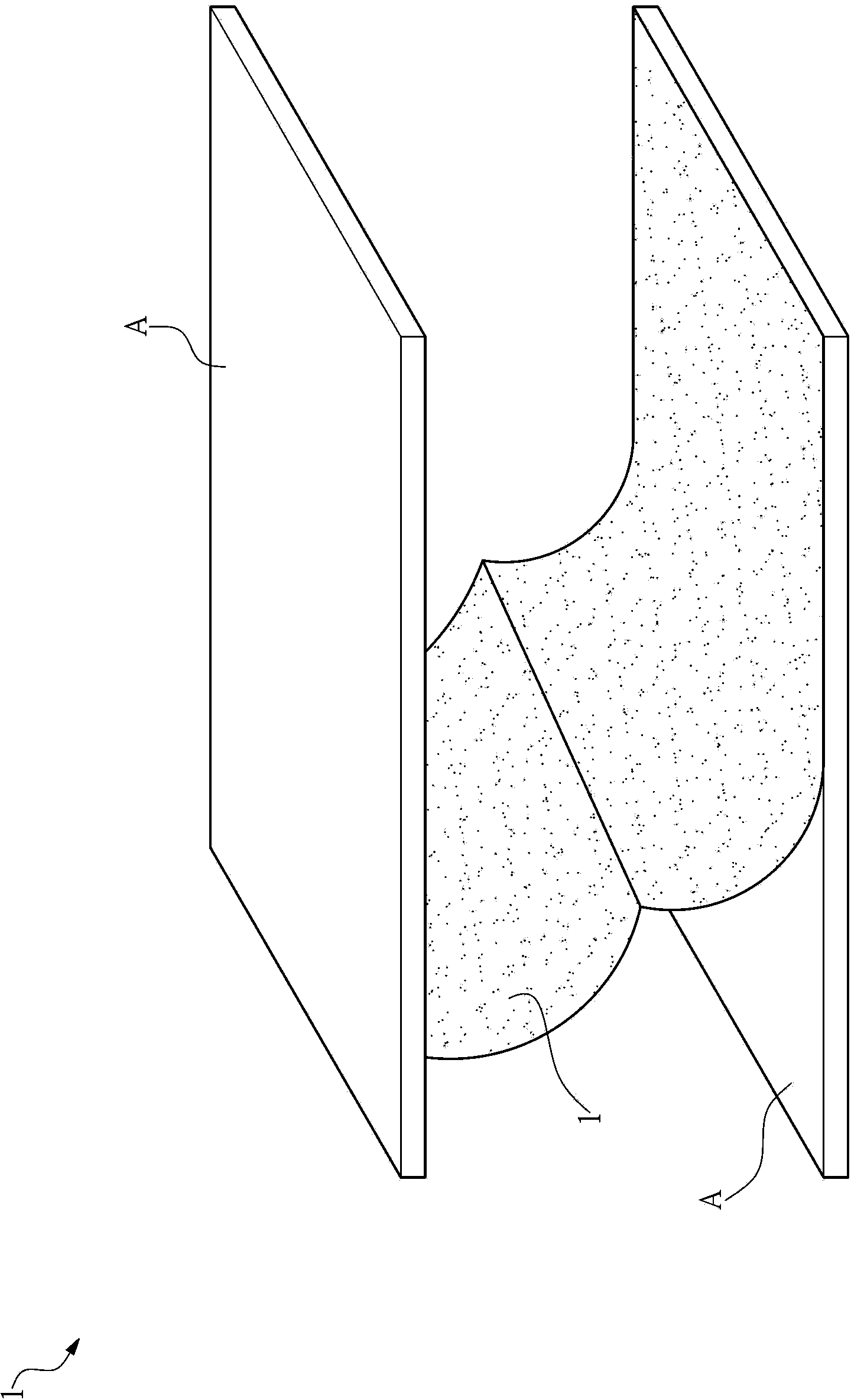

[0023] Such as Figure 4 As shown, the protective film 2 of the present invention includes a non-adhesive layer 21 and an adhesive layer 22, the non-adhesive layer 21 further includes a surface layer 211 and an intermediate layer 212; the total thickness of the protective film 2 is between 10 ~ 100um, wherein the non-adhesive The thickness of the surface layer 211 of the layer 21 is no more than 20% of the total thickness of the protective film 2, the thickness of the middle layer 212 is between 60% and 95% of the total thickness of the protective film 2, and the thickness of the adhesive layer 22 is between 60% and 95% of the total thickness of the protective film 2. 5~25%. In addition, the non-adhesive layer 21 and the adhesive layer 22 of the present invention are combined by a co-extrusion method without the need for coating processing, so as to reduce processing costs and reduce environmental pollution caused by coating processing.

[0024] Among them, the non-adhesive l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com