Method for relieving peculiar smell of tipping paper

A technology of tipping paper and odor, applied in papermaking, paper coating, textiles and papermaking, etc., can solve problems affecting human health and cigarette smell, odor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

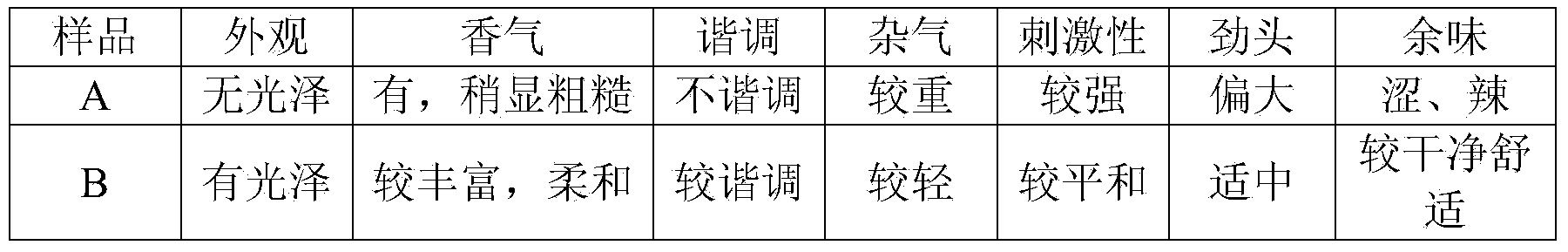

Image

Examples

Embodiment 1

[0024] A method for improving the peculiar smell of tipping paper, comprising the steps of:

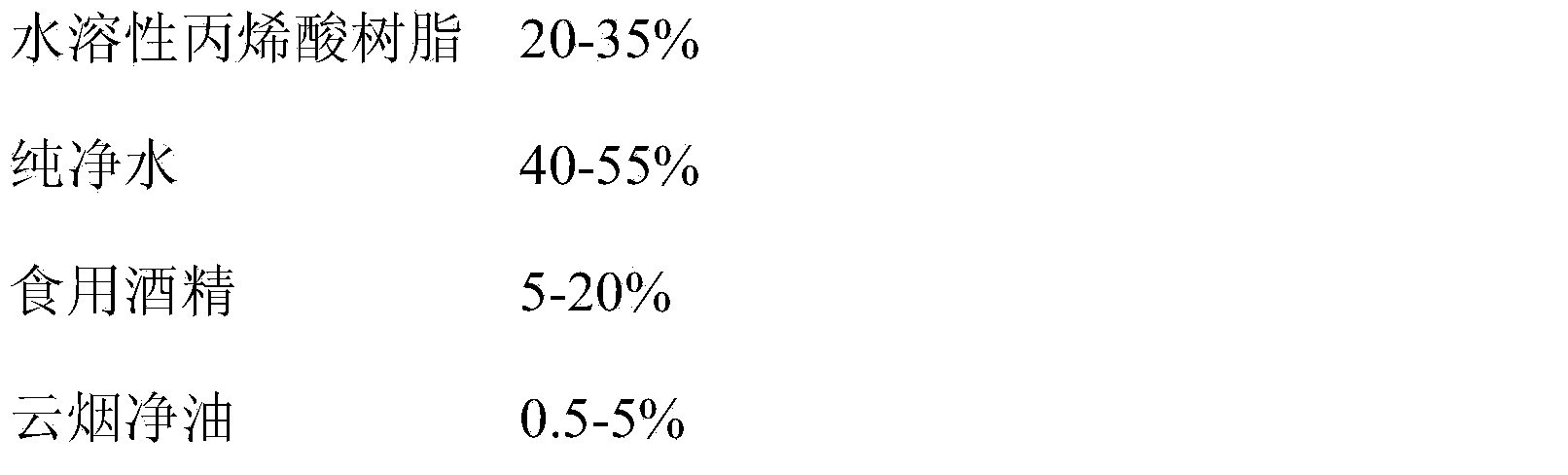

[0025] (1) Prepare the water-based resin primer according to the following weight percentage, and mix evenly:

[0026]

[0027] (2) Uniformly coat one layer of the water-based resin primer on the tipping paper base paper, as the base layer, the coating amount is controlled at 1 g / square meter, and then baked at a temperature of 90 ° C for 10 seconds;

[0028] (3) Print the ink layer on the primer layer, use electrostatic ink absorption to color the printing surface ink, the printing pressure is 0.3MPa, the printing ink viscosity is 12s, the printing plate roller is a laser engraving plate roller, and then baked at a temperature of 90°C 10S;

[0029] (4) Prepare water-based resin sealing solution according to the following weight percentage, and mix well:

[0030]

[0031] (5) Uniformly coat one layer of the water-based resin sealing solution on the surface of the ink layer, as...

Embodiment 2

[0034] A method for improving the peculiar smell of tipping paper, comprising the steps of:

[0035] (1) Prepare the water-based resin primer according to the following weight percentage, and mix evenly:

[0036]

[0037] (2) Uniformly coat one layer of the water-based resin primer on the tipping paper base paper, as the base layer, the coating amount is controlled at 1.2 g / square meter, and then baked at a temperature of 100 ° C for 12 seconds;

[0038] (3) Print the ink layer on the primer layer, use electrostatic ink absorption to color the printing surface ink, the printing pressure is 0.5MPa, the printing ink viscosity is 14s, the printing plate roller is a laser engraving plate roller, and then baked at a temperature of 90°C 10S;

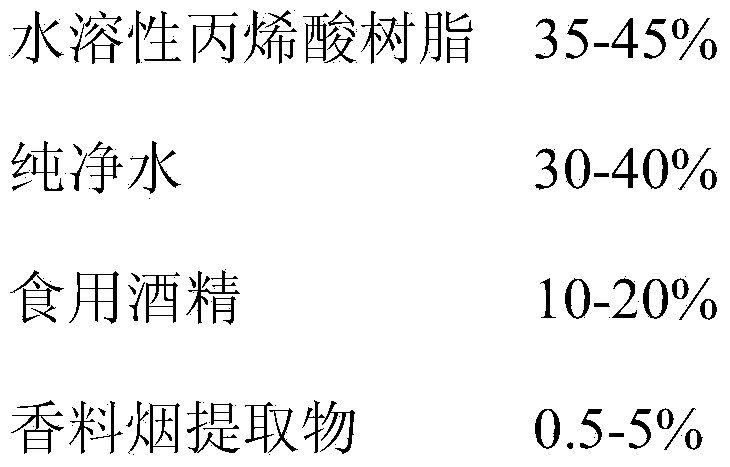

[0039] (4) Prepare water-based resin sealing solution according to the following weight percentage, and mix well:

[0040]

[0041] (5) Uniformly coat one layer of the water-based resin sealing solution on the surface of the ink layer,...

Embodiment 3

[0044] A method for improving the peculiar smell of tipping paper, comprising the steps of:

[0045] (1) Prepare the water-based resin primer according to the following weight percentage, and mix evenly:

[0046]

[0047] (2) Uniformly coat one layer of the water-based resin primer on the tipping paper base paper, as the primer, the coating amount is controlled at 0.8 g / square meter, and then baked at a temperature of 95° C. for 11 seconds;

[0048] (3) Print the ink layer on the primer layer, use electrostatic ink absorption to color the printing surface ink, the printing pressure is 0.5MPa, the printing ink viscosity is 13s, the printing plate roller is a laser engraving plate roller, and then baked at a temperature of 95°C 10S;

[0049] (4) Prepare water-based resin sealing solution according to the following weight percentage, and mix well:

[0050]

[0051] (5) Uniformly coat one layer of the water-based resin sealing solution on the surface of the ink layer, as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com