Transmission device for high-pressure production line caterpillar-tractor

A transmission device and production line technology, applied in the field of tractors, can solve problems such as the unbalanced force on the main shaft of the upper turbine box, and achieve the effects of solving the unbalanced force, reducing the bearing damage rate and reducing the maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

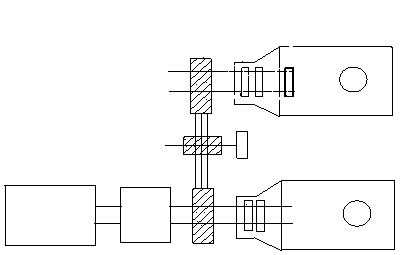

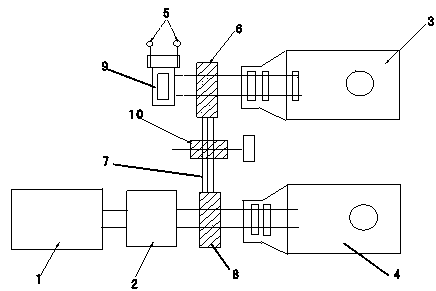

[0011] Such as figure 1 As shown, a high-voltage production line crawler tractor transmission device according to the present invention includes a DC motor 1, a gearbox 2, an upper turbine box 3 and a lower turbine box 4, and the main shafts of the DC motor 1 and the lower turbine box 4 Connected, a gearbox 5 is provided on the main shaft between the DC motor 1 and the lower worm case 4, and a lower synchronous pulley 6 is provided on the main shaft between the gearbox 5 and the lower worm case 4, and the synchronous Belt 7 is connected with upper synchronous pulley 8; Upper synchronous pulley 8 is arranged on the main shaft of upper worm case 3 above lower worm case 4; The two disk bearings in the main shaft of the upper turbine box 3 are the same anti-pull supporting device 9 as the external support point.

[0012] A belt pressure pulley 10 is provided at the synchronous belt 7 between the upper and lower synchronous wheels 8 and 6 .

[0013] Two pull rings 11 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com