Air duct component of air conditioner

A technology of air duct components and air conditioners, which is applied in the direction of pipeline layout, heating and ventilation cover/cover, etc., which can solve the problems of easy damage of foam forming air duct, complex production process requirements, and increase of thermal insulation materials, etc., to achieve improved heat insulation Effect, prevention of heat exchange phenomenon, effect of small thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

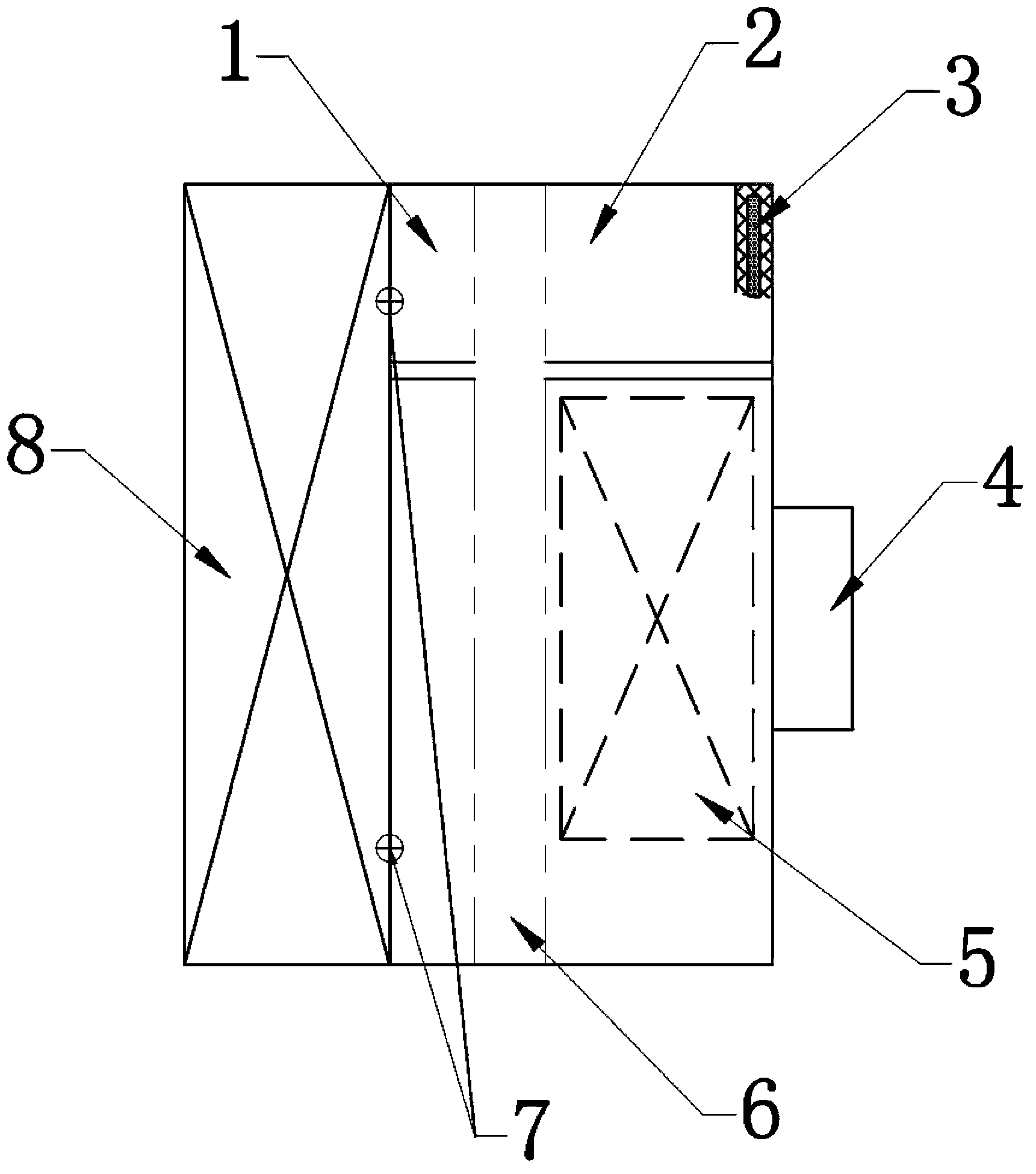

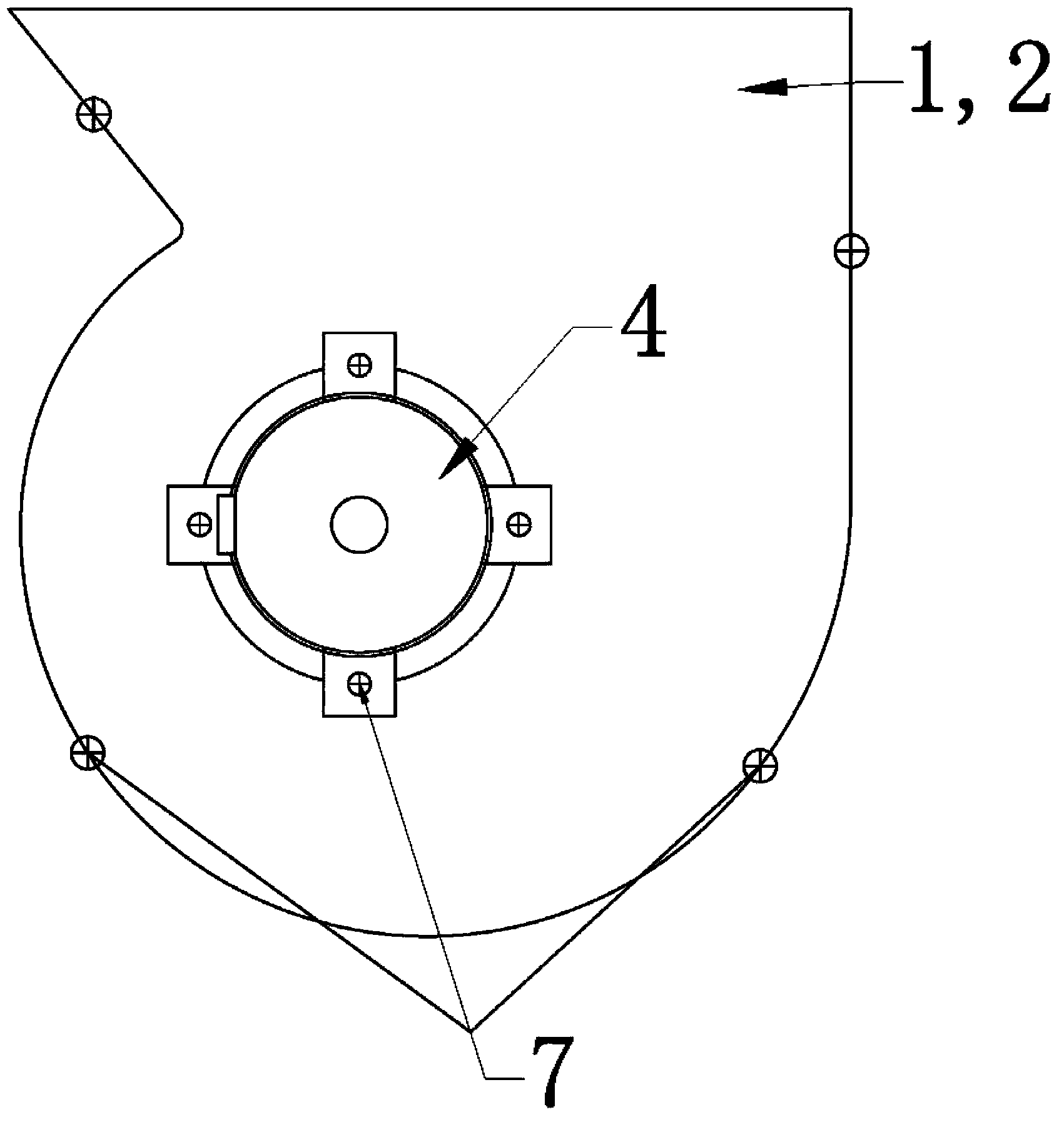

[0020] See figure 1 with figure 2 , The air duct assembly of the air conditioner in this embodiment includes a front air duct housing 1 , a rear air duct housing 2 , a motor 4 , a wind wheel 5 and a sealing sponge 6 .

[0021] Both the front air duct housing 1 and the rear air duct housing 2 are hollow, and the hollow interiors are filled with nitrogen 3 . The front air channel casing 1 is fixedly connected with the rear air channel casing 2 . The inner wall and the outer wall of the front air duct housing 1 and the rear air duct housing 2 are all made of ABS plastic material. The motor 4 is fixed on the housing 2 of the rear air duct. The wind wheel 5 is arranged in the air duct surrounded by the front air duct housing 1 and the rear air duct housing 2 , and is fixed on the output shaft of the motor 4 . The sealing sponge 6 is pasted at the docking position between the front air duct housing 1 and the rear air duct housing 2 . The evaporator cooling assembly 8 of the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com