Carbon dioxide refrigeration device structure

A carbon dioxide and refrigeration device technology, which is applied in the direction of household refrigeration devices, refrigerators, refrigeration components, etc., can solve the problem that carbon dioxide refrigerant cannot be liquefied, and achieve the effect of small application range, no pollution to the environment, and low system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

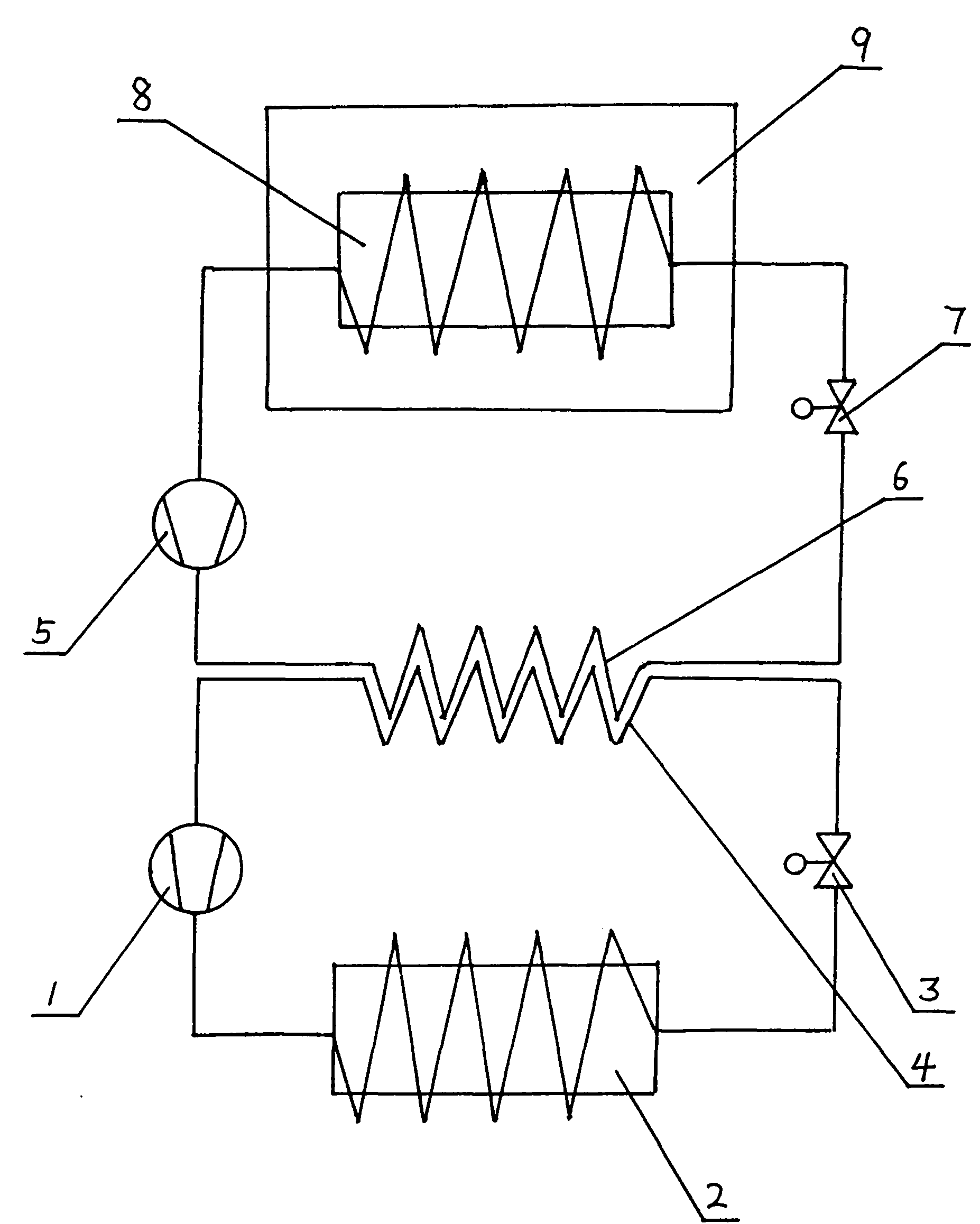

[0025] Such as figure 1 As shown, the general refrigeration device that uses carbon dioxide as the refrigerant generally adopts a cascade system refrigeration device structure, using ammonia (R717) or Freon as the refrigerant, and connecting the ammonia (R717) or Freon compressor through pipelines 1. Condenser 2. Throttle valve 3 and evaporator 4 form a high-temperature stage system; carbon dioxide is used as a refrigerant, and carbon dioxide compressor 5, condenser 6, throttle valve 7, and evaporator 8 are connected through pipelines to form a low-temperature stage system. Use the evaporator 4 of the high-temperature stage to cool down the condenser 6 that uses carbon dioxide as the refrigerant in the low-temperature stage to ensure that the carbon dioxide refrigerant operates at the critical temperature, and then pass through the evaporator 8 installed in the cold storage 9 as the refrigerant Cold storage 9 is refrigerated.

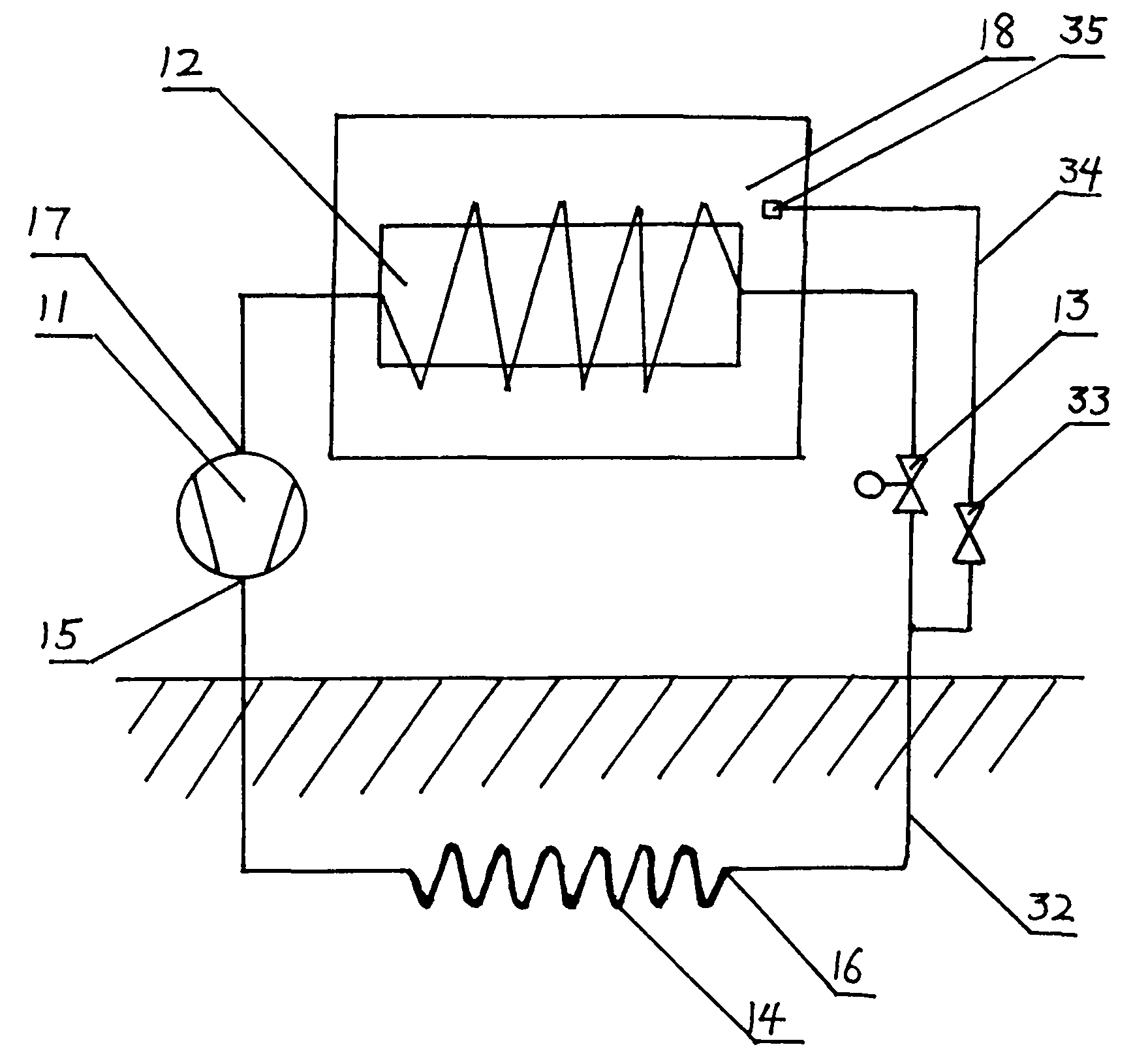

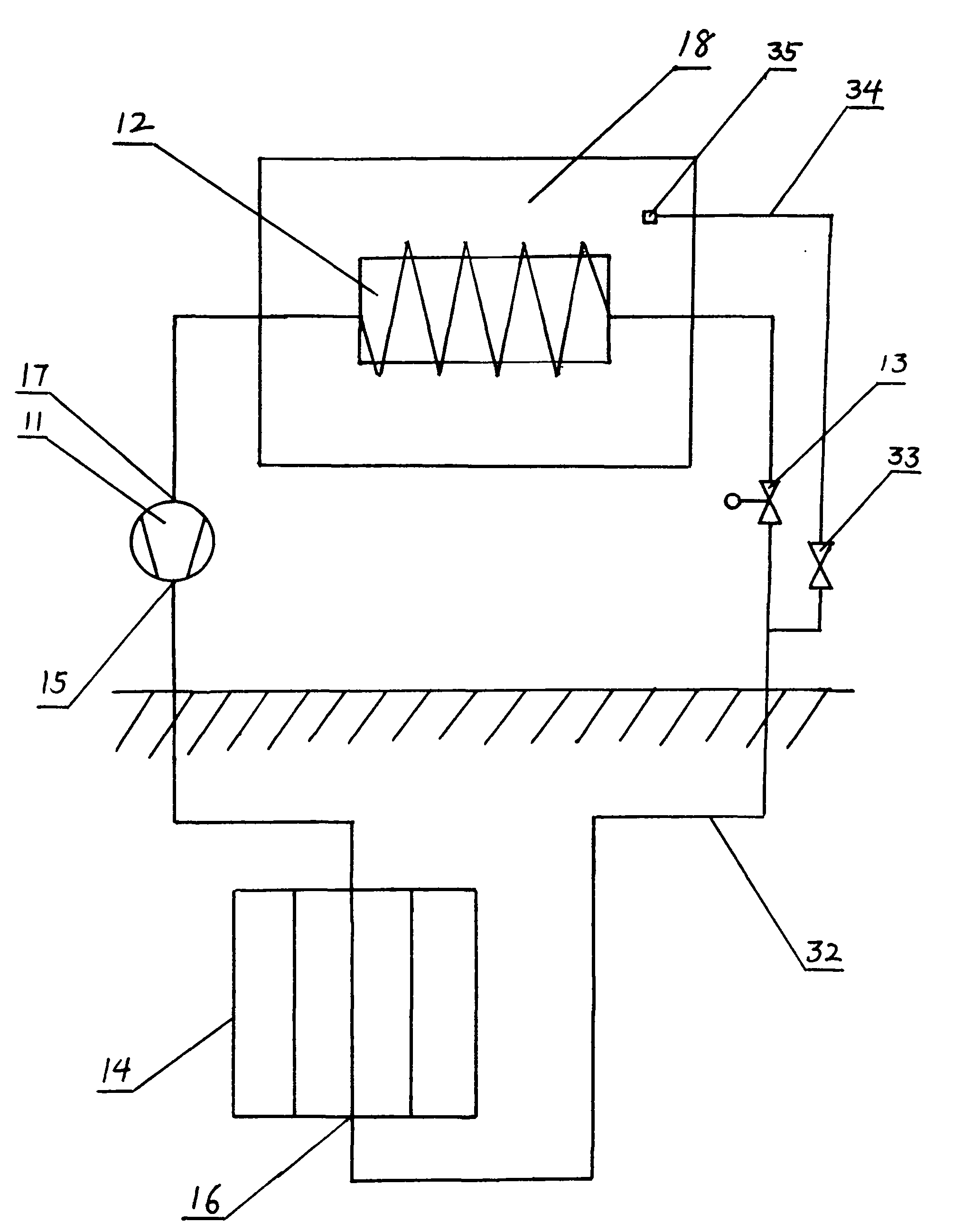

[0026] Such as figure 2 As shown, the carbon d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com