Iron core slicing table

A table and bench technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve problems such as affecting magnetic permeability, and achieve the effect of ensuring overall quality, high reliability, and eliminating the phenomenon of hurting people.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

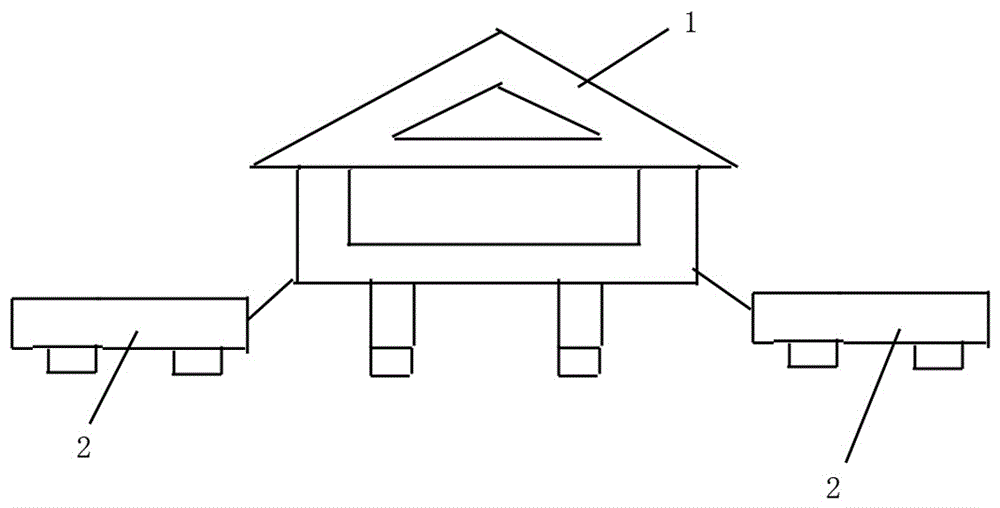

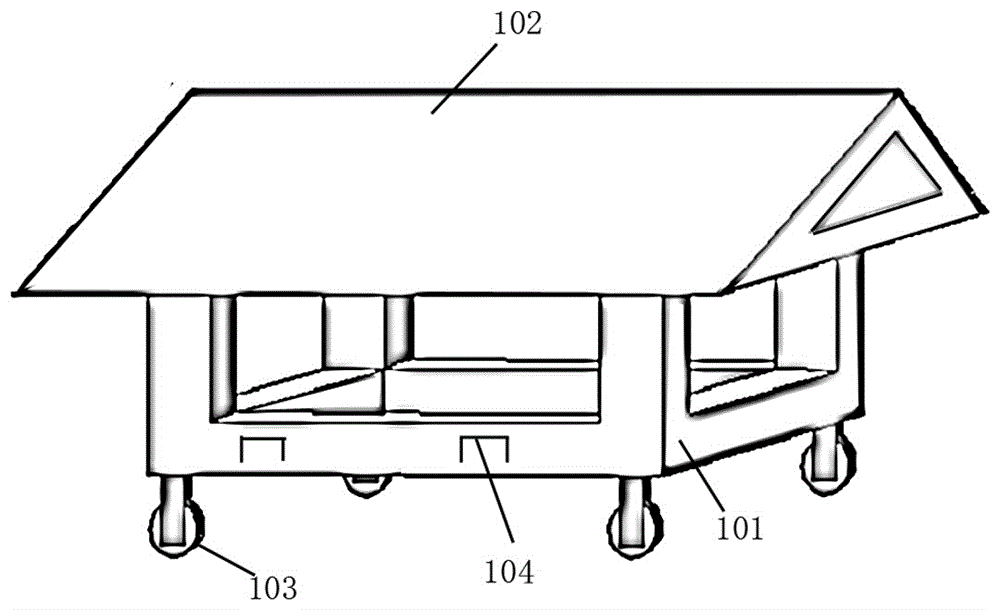

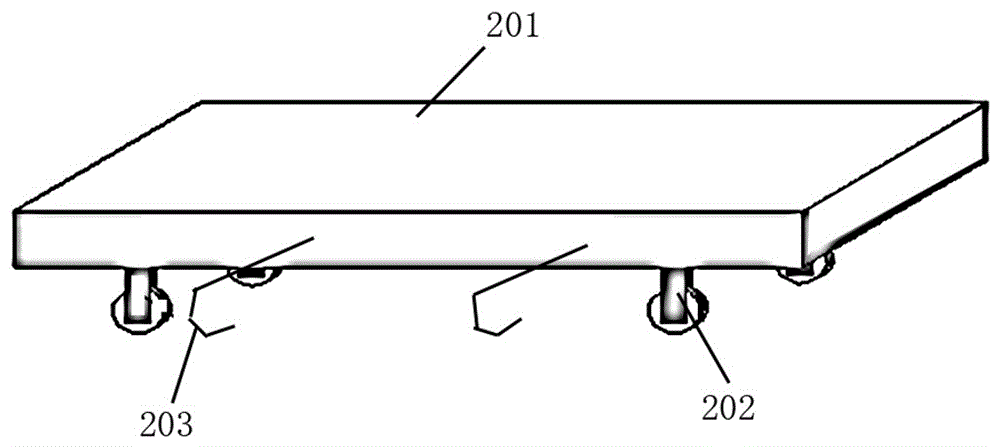

[0023] Such as Figure 1-3 As shown, it includes a fragmentation platform 1 and a splicing transport frame 2, and the splicing transport frame 2 is movably arranged on both sides of the fragmentation platform 1. Sheet stage 102, 4 universal wheels 103 are arranged below the support frame 101, and the sheet fragmentation stage 102 forms a triangular fragmentation stage by the bottom surface and two sides, and the angle between the side surface and the bottom surface of the fragmentation stage is 20 degrees; The structure is that a support base 202 is provided below the splice flat plate 201, and 4 universal wheels are installed on the support base 202; The tab plate matches the size of the core sheet.

[0024] The support frame is formed of a quadrangular support frame welded by crossbeams and longitudinal beams, and the crossbeams on both sides of the quadrilateral support frame are provided with hanging rings 104; , When splicing, connect the hook and ring to keep the splic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com