Preparation method for battery cell

A battery cell and pole piece technology, which is applied in the field of battery cell preparation, can solve problems such as increased production costs, waste of active materials, and short circuit of the cell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

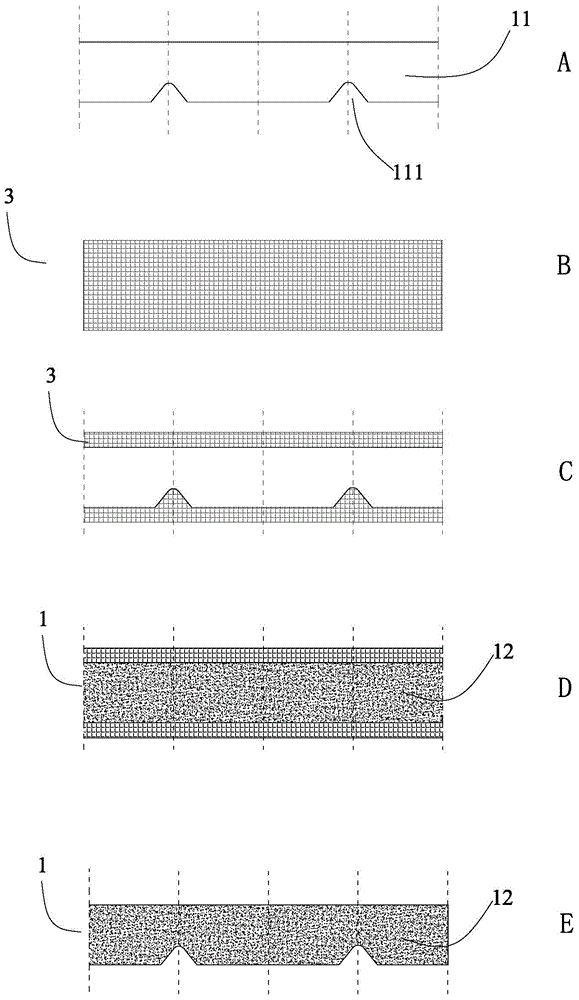

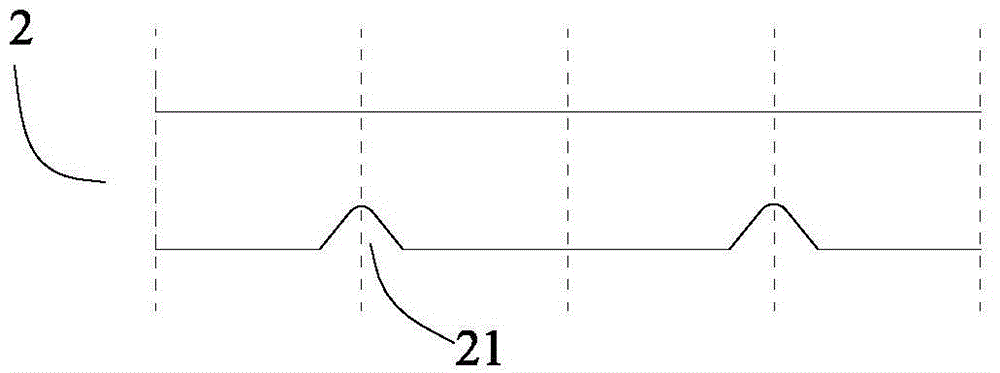

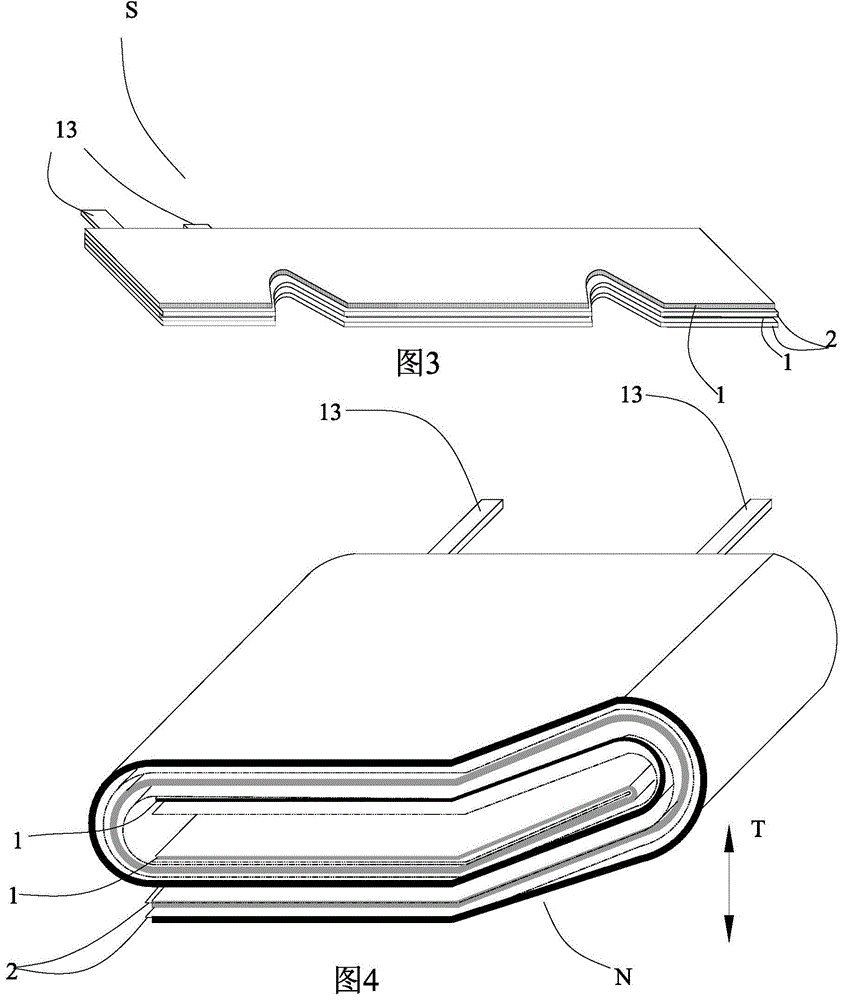

[0030] The preparation method of the battery cell according to the present invention will be described in detail below with reference to the accompanying drawings.

[0031] refer to Figure 1 to Figure 13 , according to the preparation method of the electric core of the present invention comprises the steps of: providing two pole pieces 1 with opposite polarities (refer to figure 1 and image 3 ); set the isolation film 2 (refer to figure 2 and image 3 ): Two separators 2 and two pole pieces 1 with opposite polarities are laminated alternately to form a laminate S (refer to image 3 ); winding molding: the laminated body S is wound and formed into an electric core with a notch N on the edge and / or inside (refer to Figure 4 , Figure 8 , Figure 10 , Figure 12 and Figure 13 ). Wherein, in the step of providing two pole pieces 1 with opposite polarities, each pole piece 1 in at least one pole piece 1 of the two pole pieces 1 with opposite polarities is provided as:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com