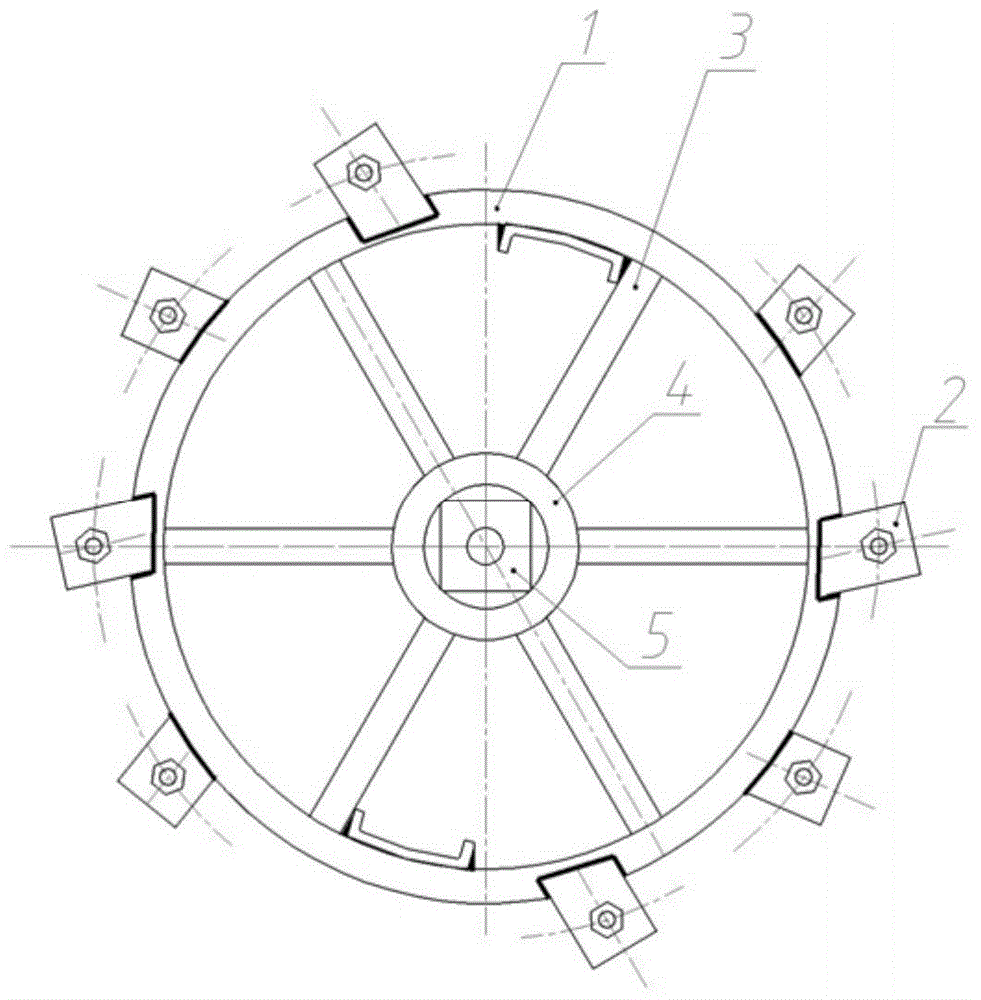

Cutter head of farmland ditcher

A trencher and cutter head technology, which is applied in the fields of excavation/covering trenches, agriculture, and applications, can solve the problems of high processing cost, inconvenient use, increased workload, etc., and achieves reduction of cutting processes, cost reduction, installation handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

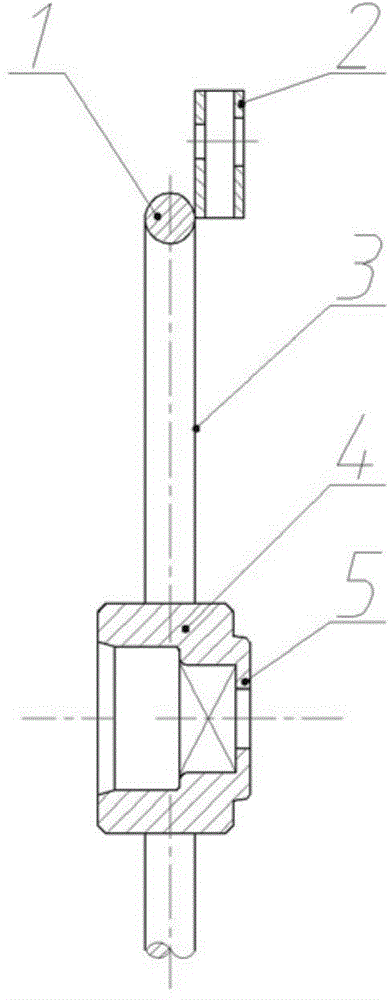

[0018] Embodiment 1: as figure 2 Shown: a partial schematic diagram of the cutter head bushing 4 of the farmland ditching machine, the bushing is made into a shape with a one-piece cover by a forging or casting process at one time.

Embodiment 2

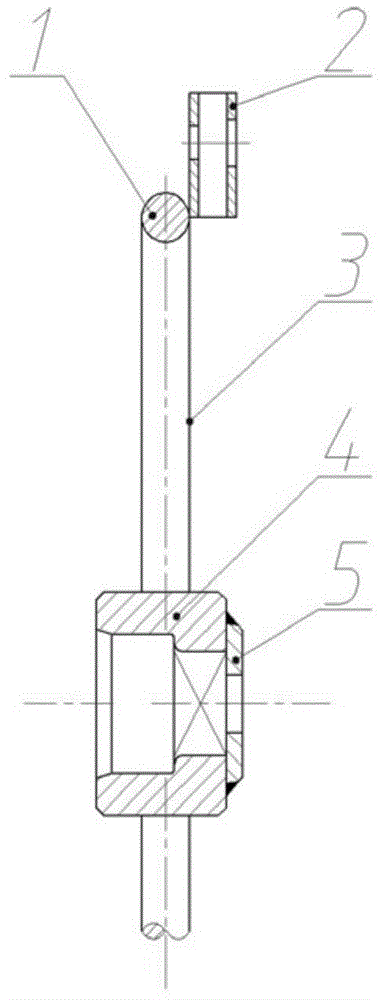

[0019] Embodiment 2: as image 3 Shown: a partial schematic diagram of the bushing 4 of the cutterhead of the farmland ditching machine, the bushing and the cover are made by welding.

Embodiment 3

[0020] Embodiment 3: as Figure 4 Shown: a partial schematic diagram of the cutter head bushing 4 of the farmland ditching machine, the bushing and the cover are made by riveting process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com