Spring mattress

A technology of mattresses and spring components, which is applied in the direction of spring mattresses, mattresses, and stuffed mattresses, etc. It can solve the problems of easy breakage of support springs, poor user feeling, and weak comfort, so as to ensure structural stability , Improve comfort, not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

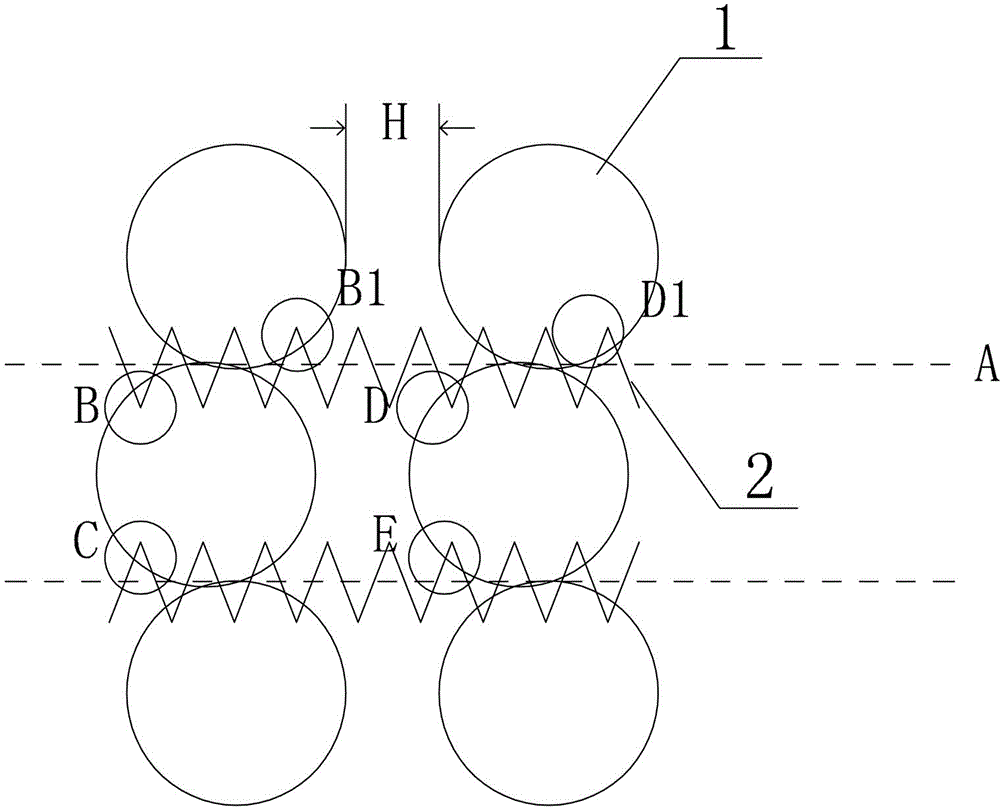

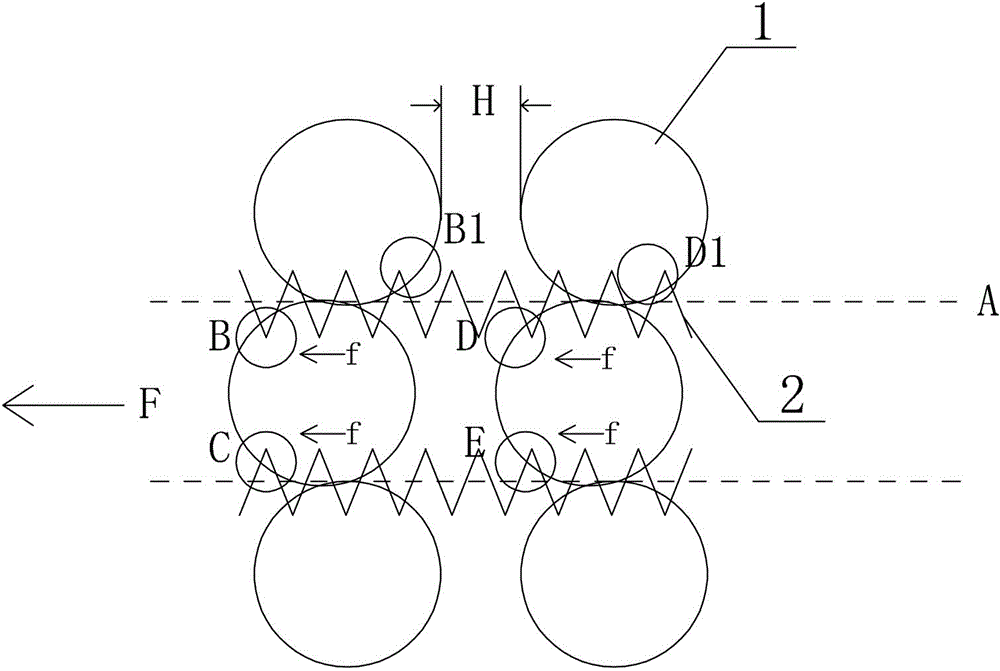

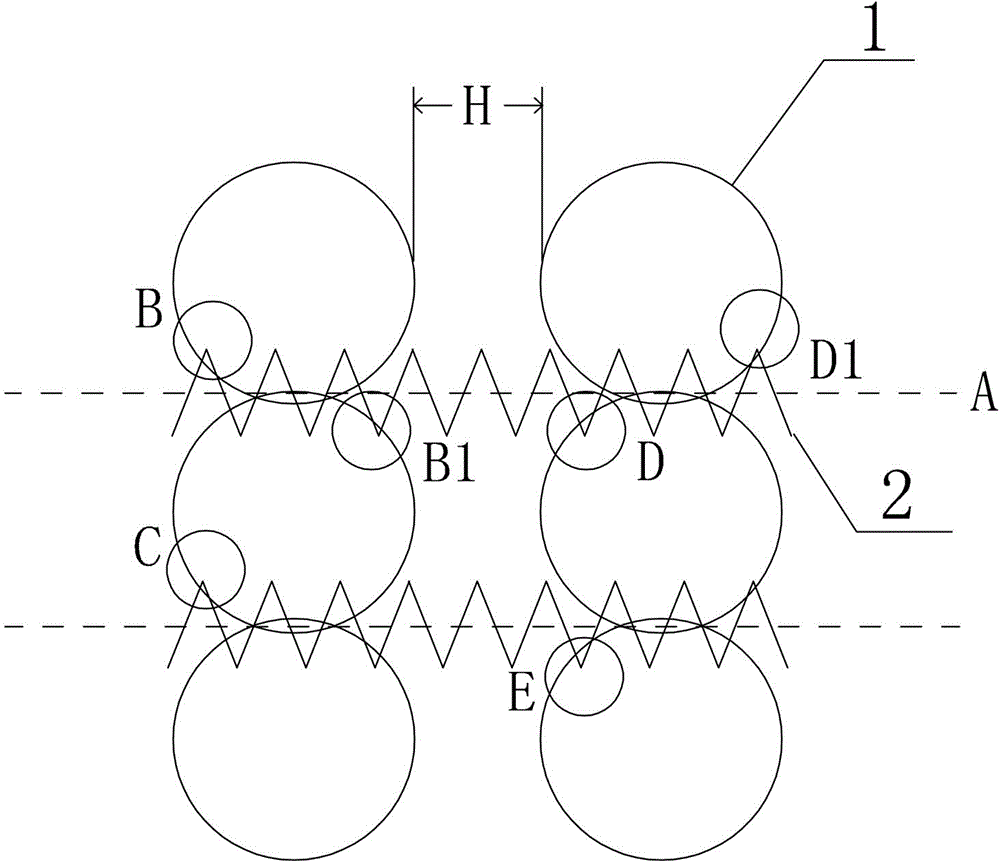

[0017] Such as image 3 , Figure 4 with Figure 5 Shown: a spring mattress, including concave springs 1, springs 2 and filling pads 3, concave springs 1 in a rectangular array, a distance H is left between concave springs 1 in adjacent rows, and concave in adjacent rows The supporting rings of the shaped springs 1 are close to each other or cross, and the through springs 2 are wound on the supporting rings of the concave springs 1 in adjacent rows.

[0018] Among the two adjacent support rings in the same row, the penetration contact part B and the penetration contact part B1 of the support ring of the spring 2 and the concave spring 1 are respectively located on both sides of the thread axis of the spring 2, and so on. Adjacent support rings are also connected with the wear spring 2 in this way.

[0019] In the two adjacent supporting rings in the same row, the penetration contact part B of the wearing spring 22 and the supporting ring of the first concave spring and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Free height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com