Method for reinforcing performance of ultrafiltration membrane by using bismuth-modified zeolite precoated layer

A modified zeolite and pre-coating technology, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of low organic matter removal rate and ultrafiltration membrane fouling, so as to improve anti-pollution ability and delay Membrane fouling and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

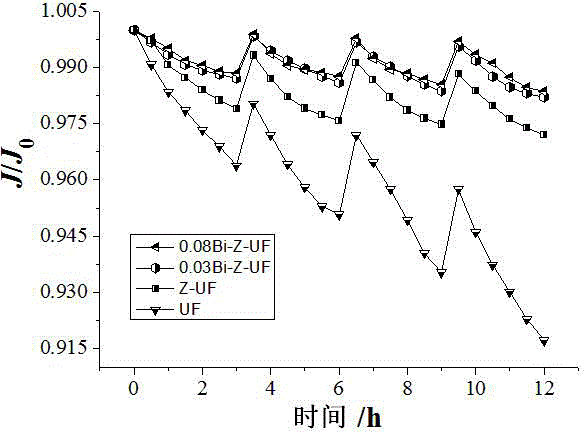

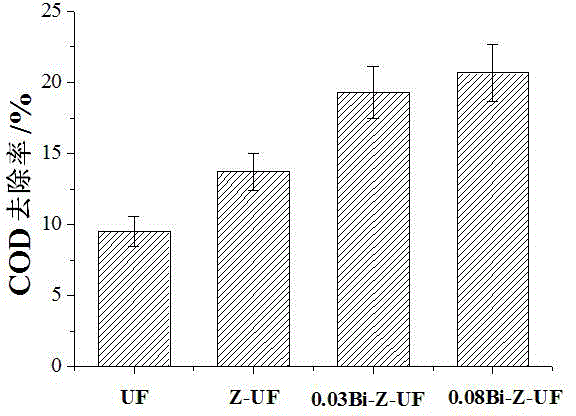

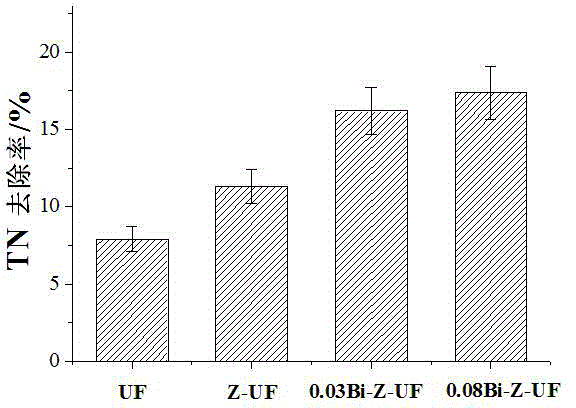

[0031] Example 1 (Using the bismuth-modified zeolite pre-coating method of the present invention to enhance the performance of ultrafiltration membranes, abbreviated as 0.03 Bi-Z-UF):

[0032] The raw water is the tail water of an industrial sewage treatment plant (COD 58mg / L, TN 19.2mg / L). The preparation method of bismuth-modified zeolite pre-coating material is as follows: (1) Add zeolite with a particle size of 1000 mesh into 0.1 mol / L sulfuric acid at a solid-to-liquid ratio of 1:5, and dynamically immerse it for 18 hours at an oscillation speed of 20 r / min. Pour out the supernatant, wash it once with pure water, and dry it at 85°C after pouring out the supernatant; (2) Add the zeolite prepared in step (1) to a 0.03 mol / L bismuth nitrate solution, dynamically immerse at an oscillation speed of 200r / min for 18h, pour out the supernatant and dry at 85°C; (3) put the zeolite prepared in step (2) at 450°C Calcining at lower temperature for 3 hours to obtain the bismuth-mod...

Embodiment 2

[0033] Example 2 (Using the bismuth-modified zeolite pre-coating method of the present invention to enhance the performance of ultrafiltration membranes, abbreviated as 0.08 Bi-Z-UF):

[0034]The raw water is the tail water of an industrial sewage treatment plant (COD 58mg / L, TN 19.2mg / L). The preparation method of bismuth-modified zeolite pre-coating material is as follows: (1) Add zeolite with a particle size of 1000 mesh into 0.1 mol / L sulfuric acid at a solid-to-liquid ratio of 1:5, and dynamically immerse it for 18 hours at an oscillation speed of 20 r / min. Pour out the supernatant, wash it once with pure water, and dry it at 85°C after pouring out the supernatant; (2) Add the zeolite prepared in step (1) with a solid-to-liquid ratio of 1:5 into the mol / L bismuth nitrate solution, dynamically immerse at an oscillation speed of 200r / min for 18h, pour out the supernatant and dry at 85°C; (3) put the zeolite prepared in step (2) at 450°C Calcining at lower temperature for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com