Material static mixer for aramid fiber pre-polymerization

A static mixer and pre-polymerization technology, used in fluid mixers, mixers, educts, etc., can solve the problems of continuous leakage of materials, affecting the quality of polymers, etc., to prolong the time, avoid deposition on the piston head, The effect of high equipment maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

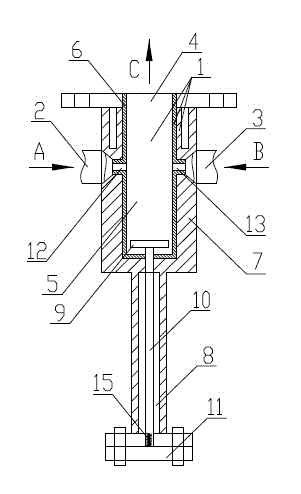

[0041] Combine now figure 1 Description of material static mixer for aramid Ⅱ prepolymerization:

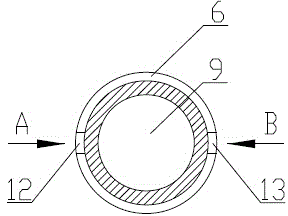

[0042] Including a mixing bin 1, a first material inlet 2, a second material inlet 3 and a material outlet 4, the mixing bin 1 includes a mixing bin inner cavity 5, a mixing bin inner wall layer 6 and a mixing bin outer wall layer 7 from the inside to the outside The discharge port 4 is set on the top of the mixing bin 1, the bottom of the mixing bin 1 is provided with a piston rod pushing bin 8, and the mixing bin inner cavity 5 and the piston rod pushing bin 8 are a mixing bin The inner wall layer 6 and the outer wall layer 7 of the mixing chamber; the bottom of the inner cavity of the mixing chamber 5 is provided with a piston head 9, and the bottom of the piston head 9 is connected to a piston push rod 10, and the piston push rod 10 passes through the inner wall layer 6 of the mixing chamber and the outer wall layer 7 of the mixing chamber, extending from the mixing chamber ...

Embodiment 2

[0045] Combine now figure 1 Description of material static mixer for aramid Ⅱ prepolymerization:

[0046] Including a mixing bin 1, a first material inlet 2, a second material inlet 3 and a material outlet 4, the mixing bin 1 includes a mixing bin inner cavity 5, a mixing bin inner wall layer 6 and a mixing bin outer wall layer 7 from the inside to the outside The discharge port 4 is set on the top of the mixing bin 1, the bottom of the mixing bin 1 is provided with a piston rod pushing bin 8, and the mixing bin inner cavity 5 and the piston rod pushing bin 8 are a mixing bin The inner wall layer 6 and the outer wall layer 7 of the mixing chamber; the bottom of the inner cavity of the mixing chamber 5 is provided with a piston head 9, and the bottom of the piston head 9 is connected to a piston push rod 10, and the piston push rod 10 passes through the inner wall layer 6 of the mixing chamber and the outer wall layer 7 of the mixing chamber, extending from the mixing chamber ...

Embodiment 3

[0049] Material static mixer for aramid Ⅱ prepolymerization:

[0050] Including a mixing bin 1, a first material inlet 2, a second material inlet 3 and a material outlet 4, the mixing bin 1 includes a mixing bin inner cavity 5, a mixing bin inner wall layer 6 and a mixing bin outer wall layer 7 from the inside to the outside The discharge port 4 is set on the top of the mixing bin 1, the bottom of the mixing bin 1 is provided with a piston rod pushing bin 8, and the mixing bin inner cavity 5 and the piston rod pushing bin 8 are a mixing bin The inner wall layer 6 and the outer wall layer 7 of the mixing chamber; the bottom of the inner cavity of the mixing chamber 5 is provided with a piston head 9, and the bottom of the piston head 9 is connected to a piston push rod 10, and the piston push rod 10 passes through the inner wall layer 6 of the mixing chamber and the outer wall layer 7 of the mixing chamber, extending from the mixing chamber 1 to the piston rod pushing chamber 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com