Full-automatic accurate pesticide variable-flow spray control system

A spray control system and fully automatic technology, applied in spray devices, devices for capturing or killing insects, applications, etc., can solve the problems of pesticide poisoning, imperfection, and uneven spraying of operators, and achieve the effect of avoiding pesticide poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

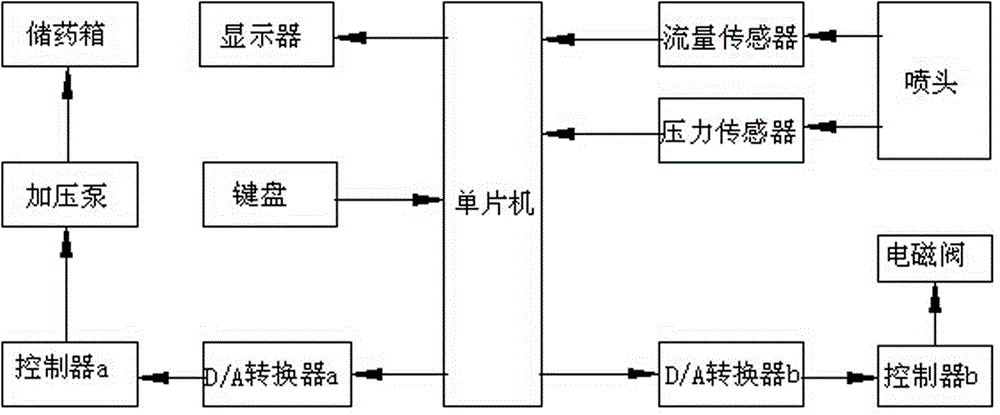

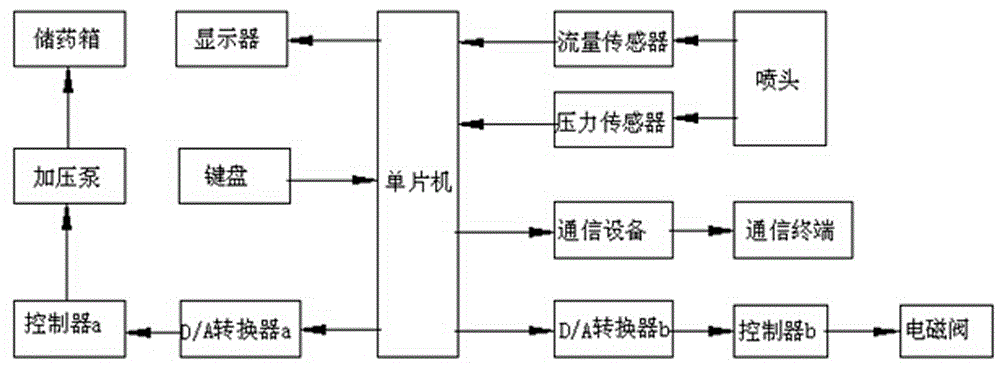

[0021] see figure 1 , a fully automatic pesticide precise variable spraying control system, including a single-chip microcomputer and a display connected to the single-chip microcomputer, a keyboard, a D / A converter a, a D / A converter a, a pressure sensor, a flow sensor, a D / A converter a and a controller a. The booster pump and the medicine storage tank are connected in sequence, and the D / A converter b is connected with the controller b and the solenoid valve in sequence. The solenoid valve, pressure sensor and flow sensor are located inside the spray head.

[0022] In the present invention, the display and the keyboard form a human-computer interaction interface. The setting of parameters and the control of the system can be realized through the human-computer interaction interface. The parameter setting includes the setting of pesticide spraying amount and nozzle pressure. By setting the pressure of the nozzle, the agriculture can be sprayed to different positions, and b...

Embodiment 2

[0024] In this embodiment, on the basis of Embodiment 1, in order to better realize the present invention, the model of the single-chip microcomputer is an ATMEGA32 single-chip microcomputer. ATMEGA32 microcontroller has the following advantages: (1) High performance, low power consumption, high cost performance; (2) Good storage performance; (3) Power-down protection function. By adopting the ATMEGA32 single-chip microcomputer, not only the manufacturing cost of the present invention can be effectively reduced, but also the storage performance of the single-chip microcomputer can be guaranteed and data loss caused by power failure can be avoided. Other parts of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0026] In this embodiment, on the basis of the above embodiments, in order to better realize the present invention, the flow sensor is connected to the single-chip microcomputer through an optical coupler. Since the flow sensor is connected to the microcontroller through an optocoupler, during data transmission, the flow sensor converts the electrical signal representing the flow into an optical signal for data transmission. The transmission process eliminates the influence of the electromagnetic field on the electrical signal of the flow sensor and transmits it to the microcontroller. The data is more accurate, and the system's ability to resist electromagnetic field interference is stronger. Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com