A Walkable Small-scale Construction Mixer

A slurry mixer and small motor technology, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of high cost of parts and components, not compact and convenient, and large body volume, etc., to achieve flexible and safe use , Simple structure, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

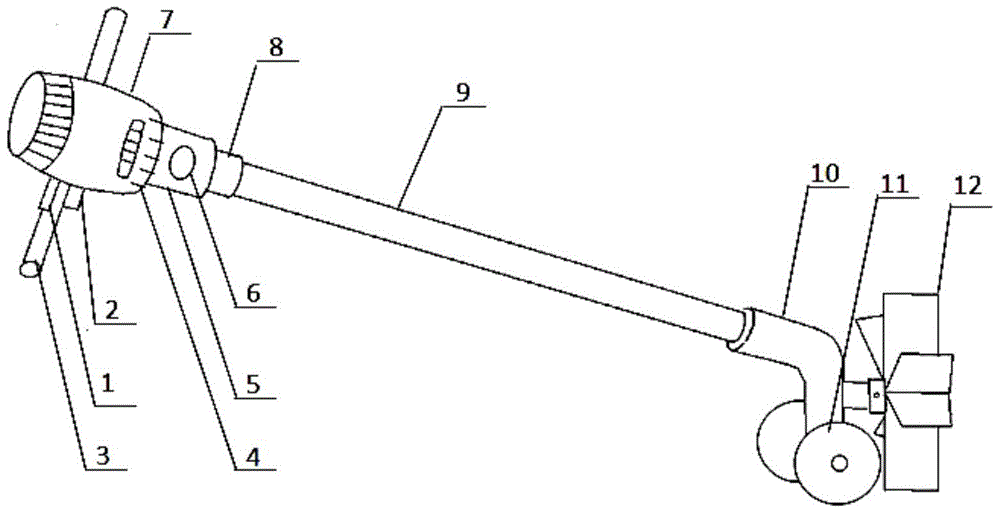

[0015] control figure 1 , a walkable small-sized pulp mixer for construction, including a handle 3, a small motor 7, a clutch sleeve 5, a transmission shaft sleeve 9, a reduction gear box 10, a walking wheel 11 and a pulp mixing plate 12, and the small motor 7 There is a motor switch 2 and a variable speed switch 1; the handle 3 is installed on both sides of the small motor 7, the small motor 7 is connected to the clutch sleeve 5 through the joint screw seat 4, and the two ends of the transmission shaft sleeve 9 are respectively connected to the clutch through the bearing sleeve 8 The casing 5 is connected with the reduction gear box 10; the traveling wheel 11 is installed under the reduction gear box 10, and the slurry mixing plate 12 is installed at the front end of the reduction gear box 10; the clutch sleeve 5 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com