Preparation method of spray-type cement concrete capable of degrading NOx

A cement concrete and concrete technology, applied in the field of photocatalysis, can solve the problem of weakening catalytic effect, and achieve the effects of efficient and continuous photocatalytic degradation, strong water permeability and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

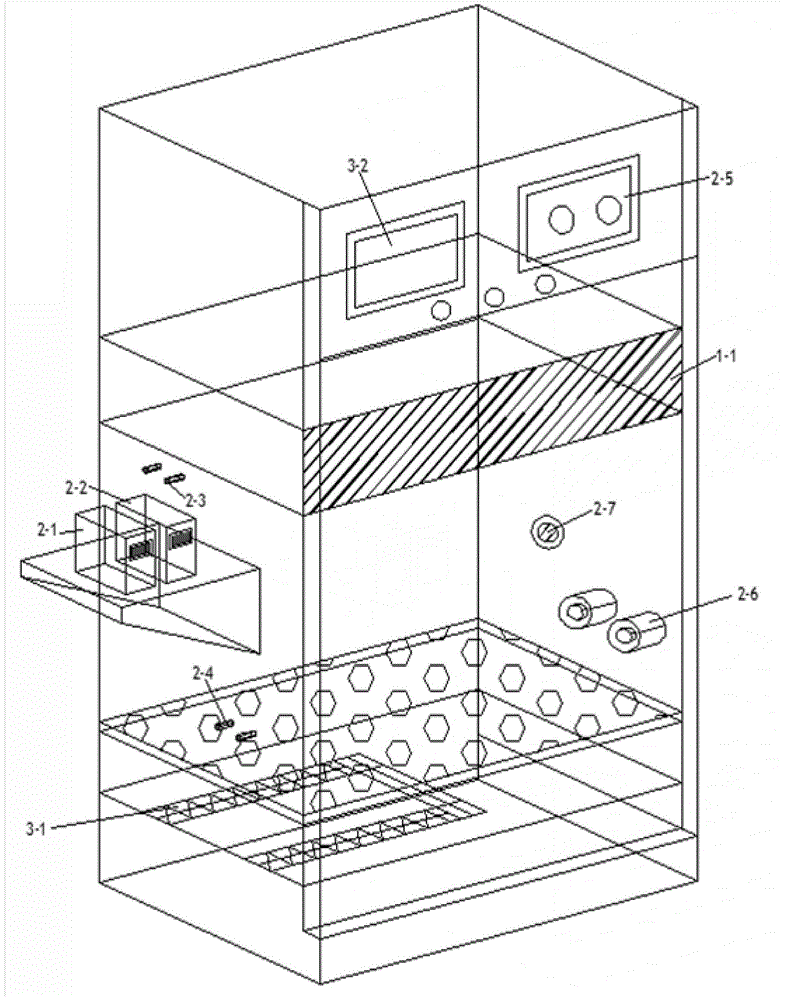

Image

Examples

Embodiment 1

[0036] (1) TiO 2 Fully mix with activated carbon at a mass ratio of 1:1 to make nano-TiO 2 The material is not easy to agglomerate and easy to disperse.

[0037] (2) Cement, TiO 2 The mixture prepared in proportion with activated carbon, concrete penetration curing agent and dispersant polycarboxylate are mixed in a ratio of 1:0.06:0.03:0.06 by weight to make a nano-titanium dioxide aqueous slurry with a mass concentration of 5g / L.

[0038] (3) Make sand-free permeable cement concrete, adopt artificial molding, cover the surface with a plastic film after molding, and let it stand for one to two days and nights at a room temperature of 20°C ± 5°C and a relative humidity greater than 50%, and then demoulding. Then the prepared nano-TiO 2 The water-based slurry was sprayed on the surface of the permeable concrete specimen within a depth of 10mm, and finally the specimen was placed in a standard curing room (temperature 20°C ± 5°C, humidity greater than 95%) for 28 days.

[0...

Embodiment 2

[0041] (1) TiO 2 Fully mix with activated carbon at a mass ratio of 1:1 to make nano-TiO 2 The material is not easy to agglomerate and easy to disperse.

[0042] (2) Cement, TiO 2 The mixture prepared in proportion with activated carbon, concrete penetration curing agent and dispersant polycarboxylate are mixed in a ratio of 1:0.1:0.03:0.06 by weight to make a nano-titanium dioxide aqueous slurry with a mass concentration of 5g / L.

[0043] (3) To make sand-free permeable cement concrete, use artificial molding, cover the surface with plastic film after molding, and let it stand for one to two days and nights at a room temperature of 20°C ± 5°C and a relative humidity greater than 50%, and then demoulding. Then the prepared nano-TiO 2 The water-based slurry was sprayed on the surface of the permeable cement concrete specimen within a depth of 10 mm, and finally the specimen was placed in a standard curing room (temperature 20°C ± 5°C, humidity greater than 95%) for 28 days ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com