Lipidated straw modified fertilizer and preparation method thereof

A technology for improving fertilizer and straw, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of inability to meet straw recycling, straw incineration waste, complicated processes, etc., to prevent phosphorus enrichment and denitrification, easy absorption, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

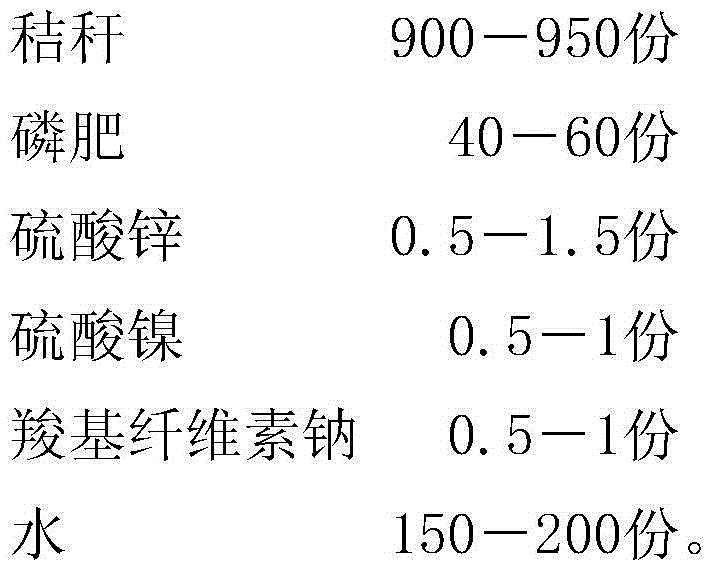

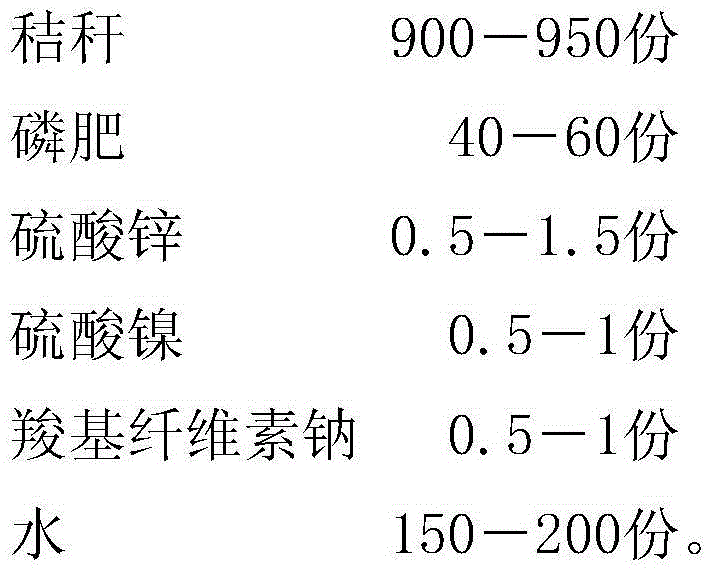

Embodiment 1

[0022] Weighing by weight components: 950 parts of plant straw, 50 parts of phosphate fertilizer, 0.5 part of nickel sulfate, 0.5 part of zinc sulfate, and 0.6 part of sodium carboxycellulose. Put the straws of the above components into the pulverizer, powder them to 80 mesh, and transport them to the mixer. Put the following components: 0.5 parts of nickel sulfate and 0.5 parts of zinc sulfate into 150 parts of water, sprinkle them on the straws and stir. Put 50 parts of phosphate fertilizer into the straw, then put 1 part of carboxycellulose sodium into 50 parts of water, while stirring, spray it in the mixer where the straw is stored, mix evenly, and put the material in the stack for 6 hours before it can be applied to the straw. Tanaka, that is, fattened straw improved fertilizer. An average of 600-1000 kg per mu is used as the base fertilizer, and an appropriate amount of nitrogen fertilizer is used.

Embodiment 2

[0024] Weighing by weight components: 950 parts of plant straw, 50 parts of phosphate fertilizer, 0.5 part of nickel sulfate, 0.5 part of zinc sulfate, 0.6 part of sodium carboxycellulose, and 200 parts of water.

[0025] Put the straw into the pulverizer to powder to 80 mesh, transport it to the mixer, then put nickel sulfate, zinc sulfate, carboxy cellulose into 200 parts of water, mix evenly, spray in the mixer where the straw is stored, and then put Phosphate fertilizer is put into the straw, mixed evenly, piled up and left for 6 hours to obtain the fattened straw improved fertilizer, and the amount of application per mu is 650 kg according to the amount of straw harvested per mu.

Embodiment 3

[0027] Raw materials were weighed according to the ratio of components by weight: 900 parts of straw, 100 parts of phosphate fertilizer, 1 part of nickel sulfate, 0.6 part of zinc sulfate, 0.5 part of carboxycellulose, and 200 parts of water.

[0028] Crush the straw to 80 mesh, put the following components into 200 parts of water and mix evenly, sprinkle on the straw powder and stir evenly, let it stand for 6 hours, and apply it to the field, 900 kg per mu.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com