Scraper type paving and compacting machine for filter sand cushion layer of canal slope

A scraper-type, paving technology, which is applied in water conservancy projects, artificial waterways, buildings, etc., can solve problems such as difficulty in guaranteeing construction quality, complicated construction technology, and high labor intensity, and achieve high paving accuracy, avoid air shock operation, The effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

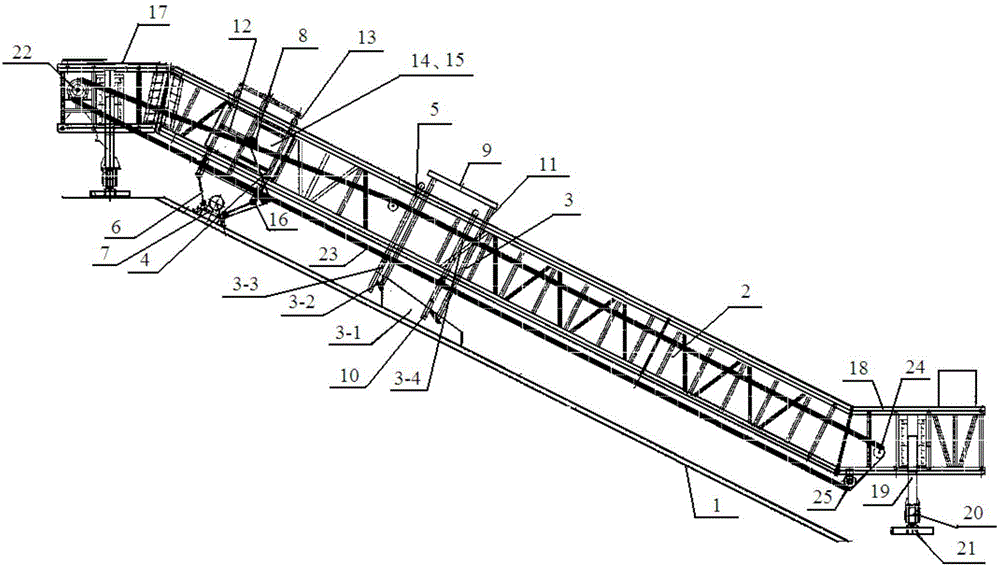

[0025] like figure 1 As shown, the present invention is a paving scraper type canal slope filter sand cushion paving compactor, the paving compactor includes a truss 2 arranged along the inclined direction of the canal slope 1, and a paving component is arranged on the truss 2 3. The shock trolley 4 and traction paving component 3 and the traction mechanism 5 that the shock trolley 4 reciprocates along the truss 2, the paving component 3 includes a paving scraper 3-1, and the paving scraper 3-1 passes through the reinforced steel 3- 2. It is connected with the fixed leg 3-3 of the paving scraper. The fixed leg 3-3 of the paving scraper passes through the sleeve 3-4 and the lower end of the extended column 11 set on the outside of the shock trolley 4. The fixed leg 10 of the paving scraper is also connected to the gantry The gantry 9 is provided with a traction mechanism 5 for the paving scraper 3-1, and the gantry 9 is provided with a height adjustment mechanism for the paving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com