Pouring formwork structure for non-standard layer structure and construction method

A non-standard layer and construction method technology, applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve problems such as inability to continue to use, achieve quality and safety savings, convenient construction, and operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

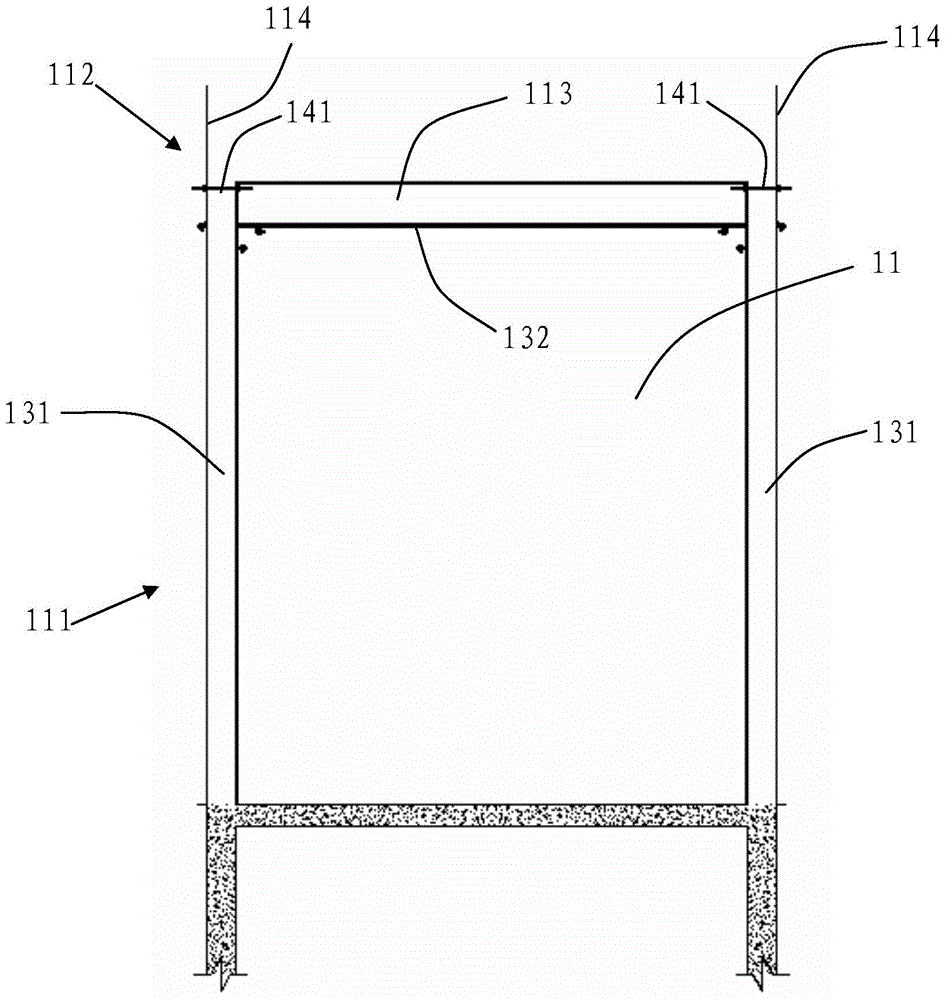

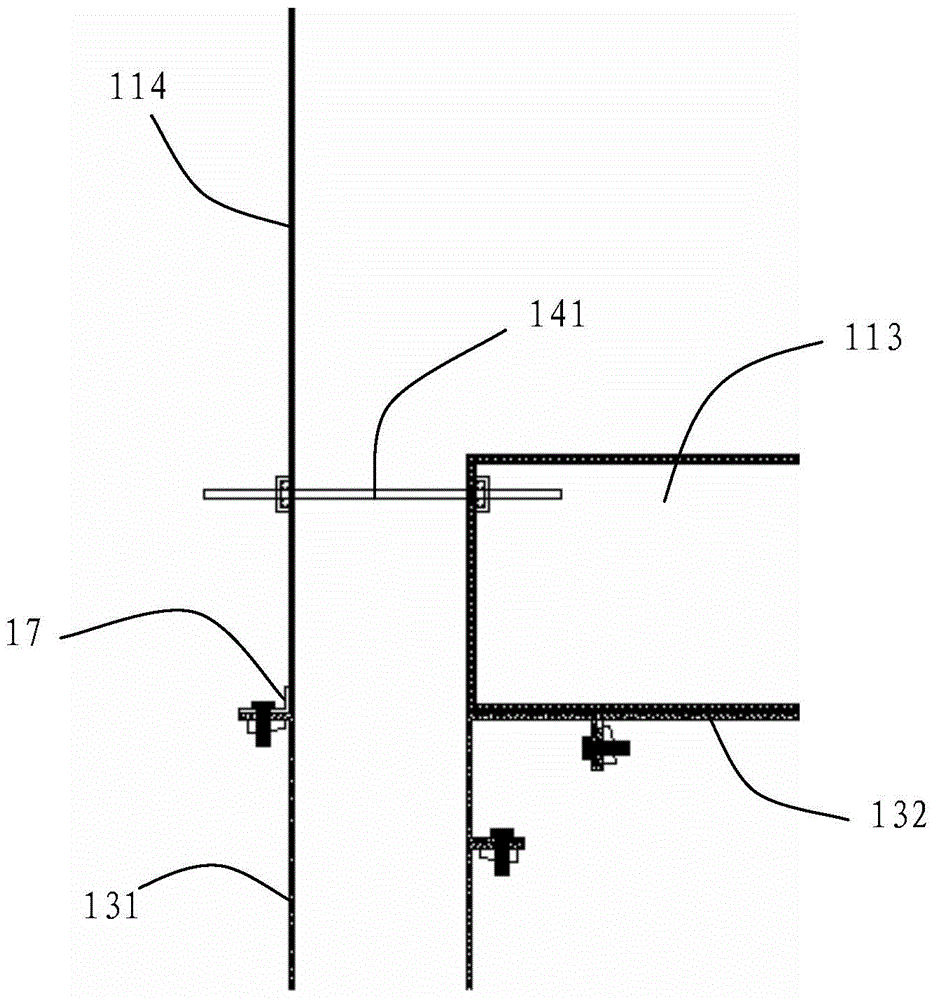

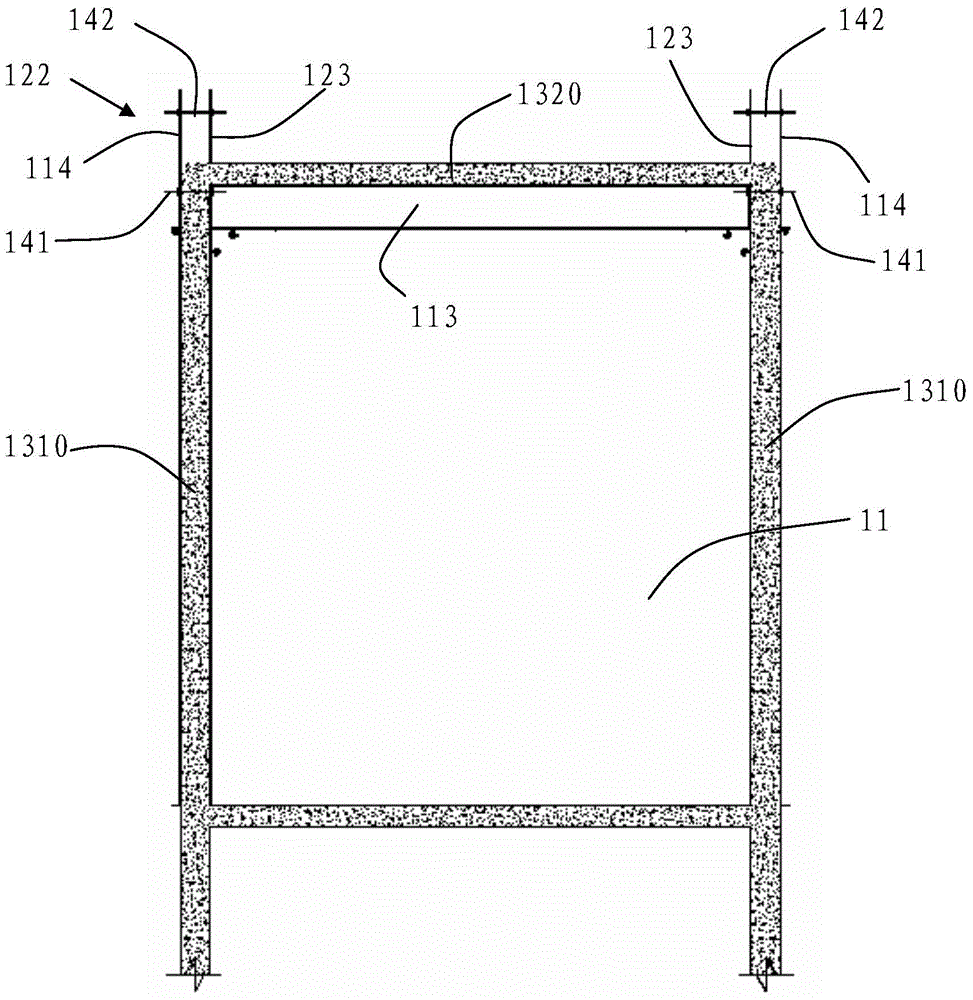

[0030] see first figure 1 with figure 2 As shown, a pouring formwork structure of a non-standard layer structure of the present invention is mainly used for constructing non-standard layers in standard layers, and the non-standard layer structure includes at least one first non-standard layer 11, the layer of the first non-standard layer 11 The height difference higher than the height of the standard layer is Δ1, and the pouring formwork structure of the first non-standard layer 11 includes the first aluminum alloy shaped formwork 111 of the standard layer and the first wooden Make lengthened formwork 112, the first aluminum alloy shaped formwork 111 is installed on the standard floor, including the first beam plate formwork 132 between the first wall column formwork 131 and the first wall column formwork 131, the first wooden lengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com