Megawatt wind power generation blade with blade-tip turbulent flow structure and forming method of megawatt wind turbine blade

A technology of wind power generator and forming method, which is applied in the direction of wind power generator components, wind power engines, wind power generation, etc., which can solve the problems of blade stability decline, wake effect enhancement, blade aerodynamic performance degradation, etc., and achieve the suppression of blade tip vortex The effect of generating, improving running stability, and improving aerodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the 1970s, R.T. Whitcomb of the National Aeronautics and Space Administration (NASA) Ames Research Center invented the winglet (Winglet, Whitcomb R T.A design approach and selected wind-tunnel results at high subsonic speeds for wing-tip mounted winglets.NASA TND-8260,1976), its function is to reduce the induced drag of the wing and weaken the wake of large aircraft to reduce the impact of aircraft wake on the airspace of the airport through the winglet.

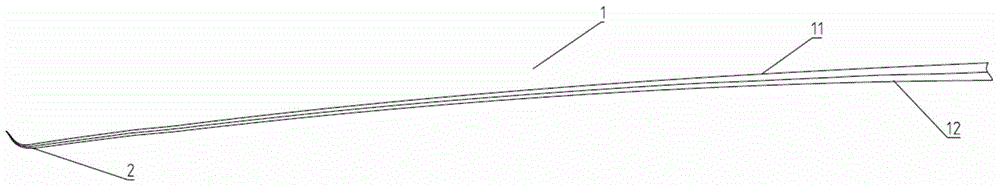

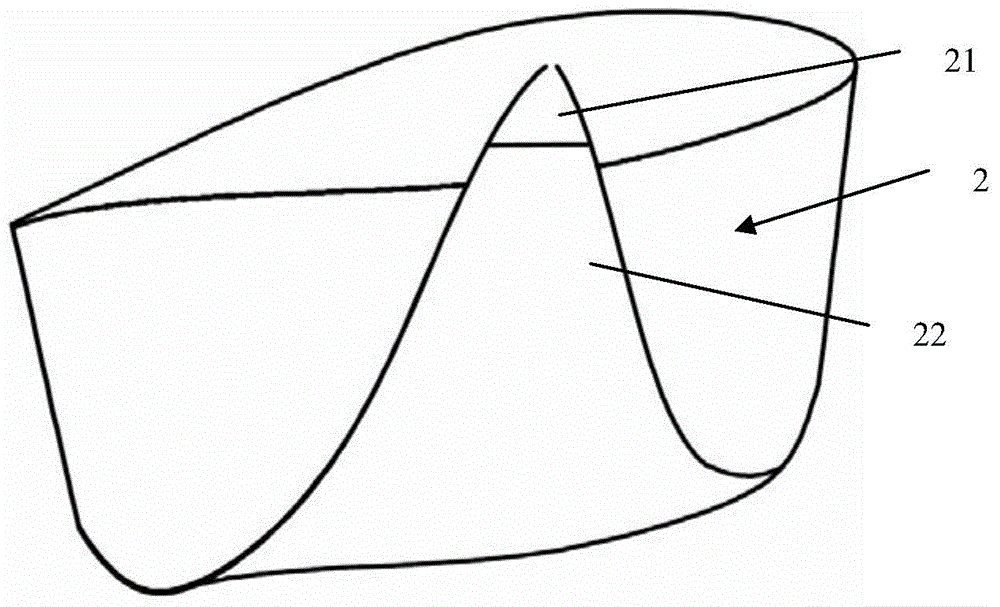

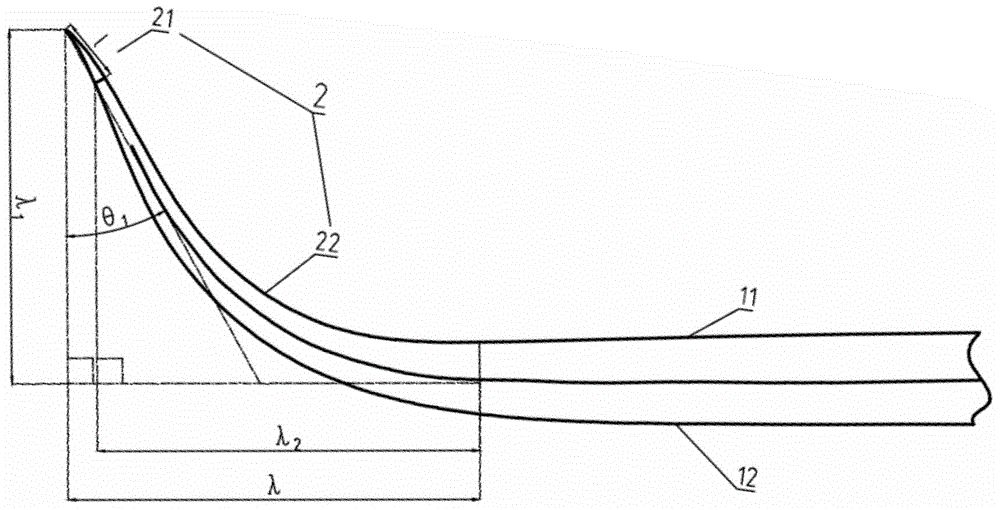

[0041] The blade tip turbulence structure designed by the present invention is based on the same principle of the winglet of the aircraft. The design of the winglet of the aircraft is suitable for the subsonic low-speed flow of 0.6-0.8Ma, while the present invention is aimed at the low-speed flow below 0.3Ma. , by installing a spoiler structure near the tip, the spoiler area of the tip is increased to form a flow opposite to the tip vortex to reduce the induced resistance, improve the aerodynamic performance of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com