Rotary splashing device

A splashing device and water splashing technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problem of poor uniformity of circumferential water distribution, and achieve uniform, moderate size, The effect of eliminating the hollow phenomenon of water distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

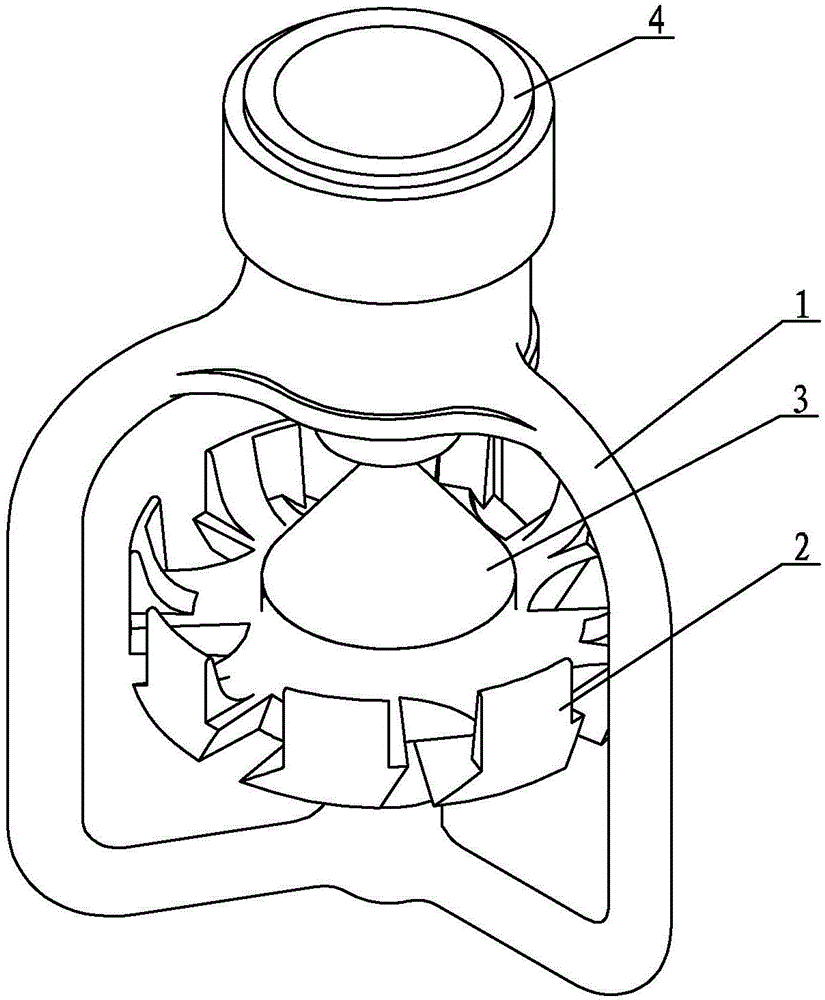

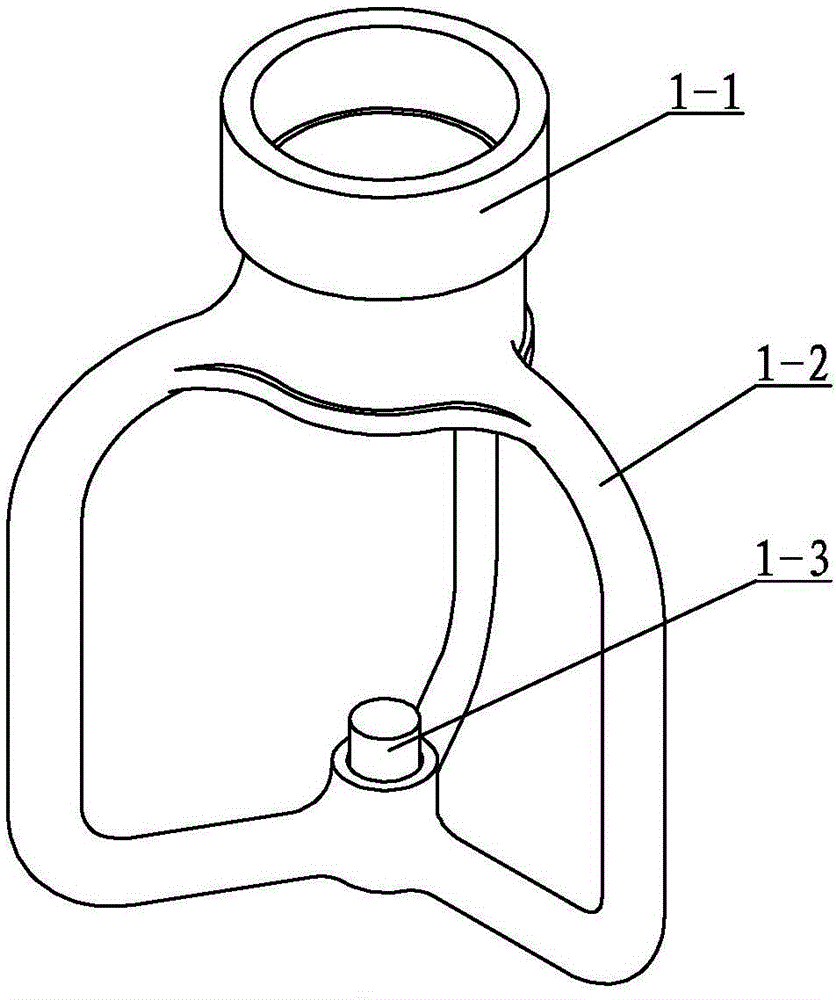

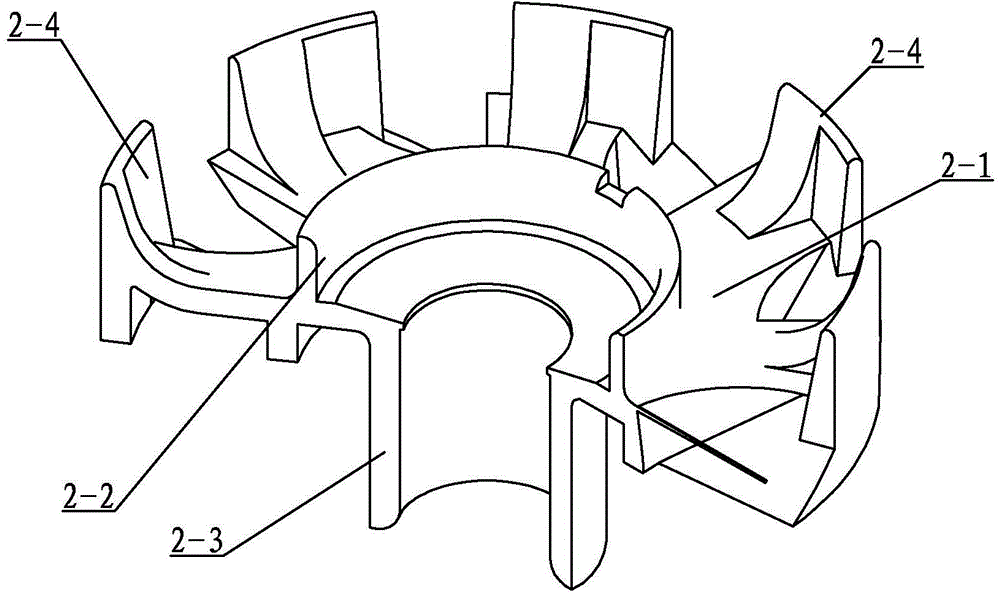

[0029] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment, this embodiment comprises skeleton 1, impeller 2, water distributor 3 and water inlet pipe 4, and described skeleton 1 is made up of placement port 1-1, support frame 1-2 and support shaft 1-3, placement port 1-1 is set on the upper end of the support frame 1-2, the support shaft 1-3 is set on the lower end of the support frame 1-2, the placement port 1-1 is set coaxially with the support shaft 1-3, and the impeller 2 is composed of the disc 2-1, The upper ring 2-2, the shaft sleeve 2-3 and several blades 2-4 are composed, the upper ring 2-2 is located above the disc 2-1, and the shaft sleeve 2-3 is located below the disc 2-1, The upper ring 2-2, the disk 2-1 and the shaft sleeve 2-3 are coaxially arranged and made into one body, and the disk 2-1 is evenly arranged with several blades 2-4 along the edge, between two adjacent blades 2-4 There is a gap between them, and the side of ...

specific Embodiment approach 2

[0030] Specific implementation mode two: combination Figure 4 To illustrate this embodiment, the driving surface 2-4-1 of this embodiment is a slope inclined from the inside to the outside and from top to bottom, and the driving angle β of the driving surface 2-4-1 is 10° to 45° . The driving angle β is small, the slope of the driving surface 2-4-1 is large, the driving force is large, and the speed of the impeller is high; the driving angle β is large, the slope of the driving surface 2-4-1 is small, the driving force is small, and the speed of the impeller is low. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0031] Specific implementation mode three: combination Figure 4 The present embodiment will be described. The driving angle β of the present embodiment is 30°. The driving angle β is at this value, which makes the driving force and impeller speed high more reasonable. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com