Concrete performance test device under the joint action of constant tensile load and erosive medium

A co-action, tensile load technology, applied in the direction of measuring device, using stable tension/pressure to test material strength, weather resistance/light resistance/corrosion resistance, etc., can solve the problems of concrete performance testing, tensile stress eccentricity, stress Slack and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

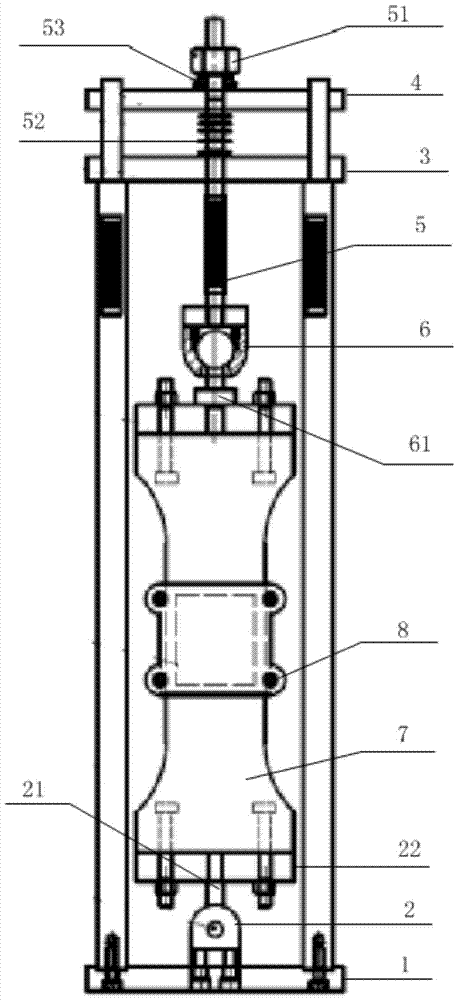

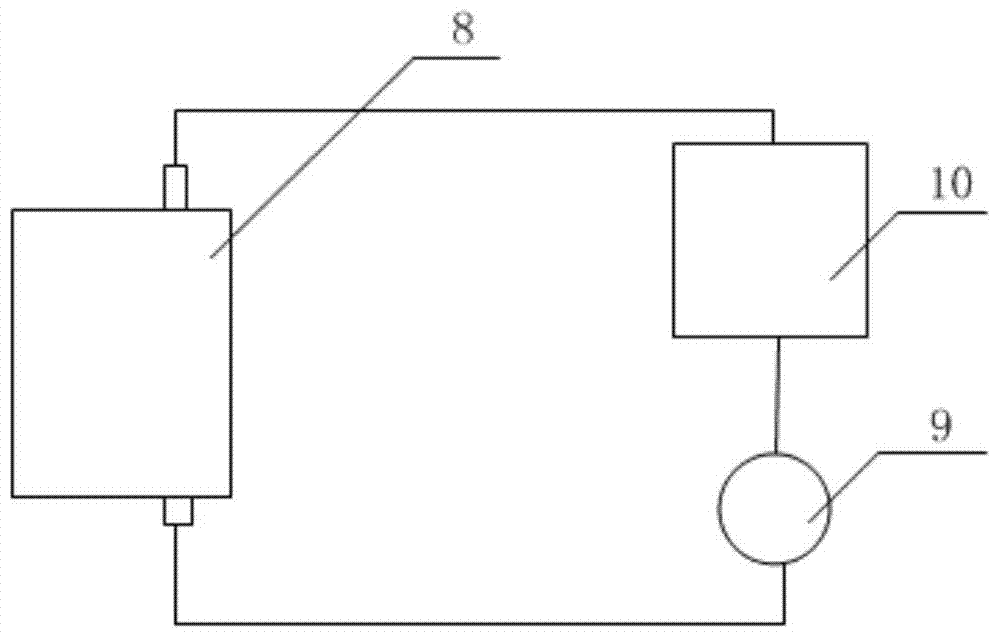

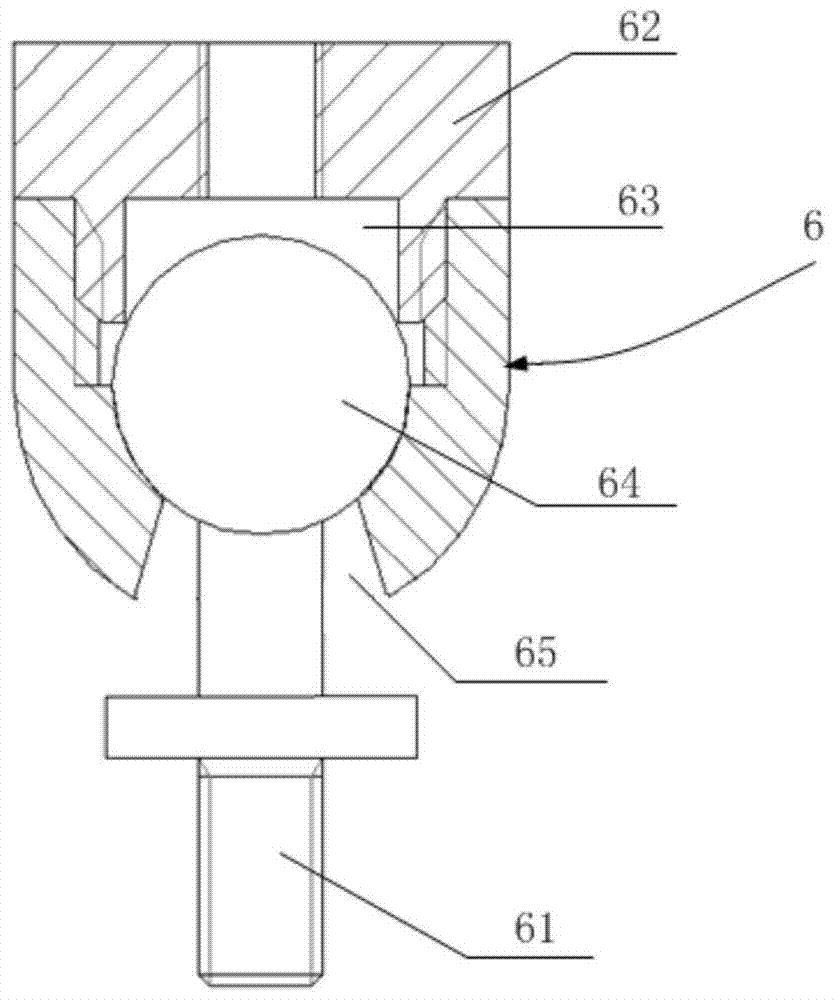

[0039] The problem to be solved by the present invention is that the tensile stress eccentricity and stress relaxation occur in the existing test device during the test process, and the performance test of concrete under the coupled action of stress and medium erosion cannot be realized. Such as figure 1 and figure 2 As shown, a concrete performance test device under the joint action of continuous constant axial tensile stress and erosive medium, which includes:

[0040] Base plate 1, on which at least four columns are fixedly connected; preferably, such as figure 1 In the shown embodiment, the bottom plate is rectangular, and the number of columns is four, which are fixedly connected to the four corners of the bottom plate by bolts.

[0041] The connecting seat 2 is fixed in the middle of the bottom plate; the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com