Method for resisting frosting and condensation in rapid temperature change experiment

A temperature change and anti-frost technology, applied in the directions of temperature control, strength characteristics, and measurement of electrical variables, to achieve the effects of avoiding rework, ensuring work efficiency, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

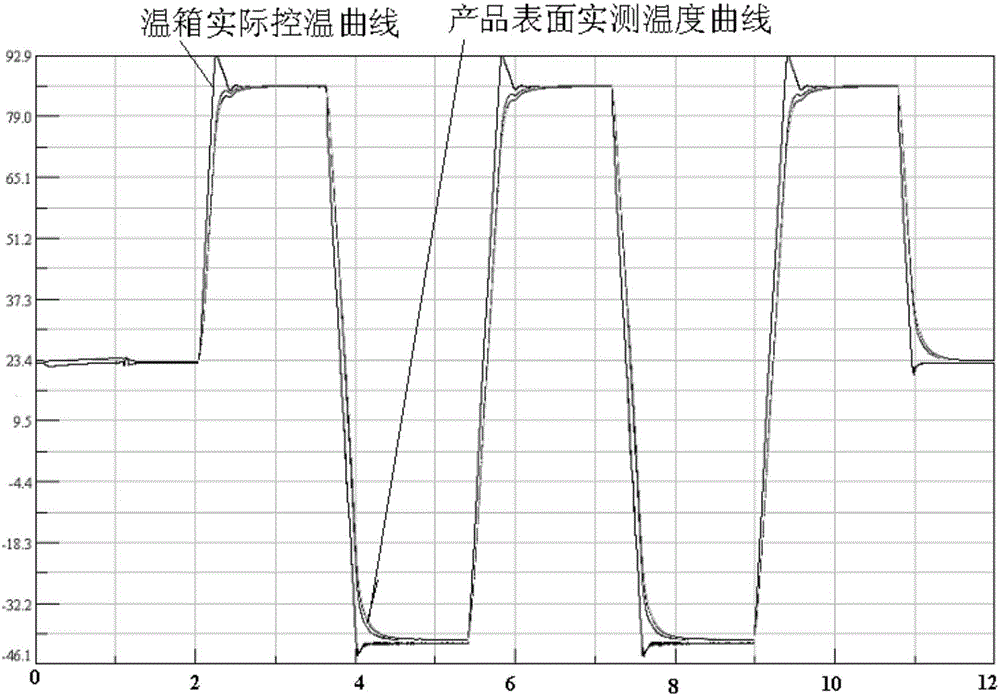

[0047] Determine the test piece

[0048] The test piece is a stand-alone product of a certain model, the product material is aluminum, and the actual weight is 1.57kg. During the test, 4 temperature measuring points T1~T4 are evenly arranged on the outer surface of the product;

[0049] Implementation steps

[0050] 1) The weighing result of the product is 1.57kg;

[0051] 2) The outer surface area of the product measured by CAD software is 736.8cm 2 ;

[0052] 3) According to the mass and area data, the product S / M value can be calculated as 469.3cm 2 / kg;

[0053] 4) According to the S / M value, determine the no-load temperature change rate of the thermostat as 5°C / min;

[0054] 5) The incubator selected for the test is the German Fuqi incubator (VTS7027-15);

[0055] 6) Compile the thermostat control program, the main parameters of which are as follows:

[0056] The no-load temperature change rate is 5°C / min;

[0057] Test temperature range -40℃~+85℃;

[0058] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com