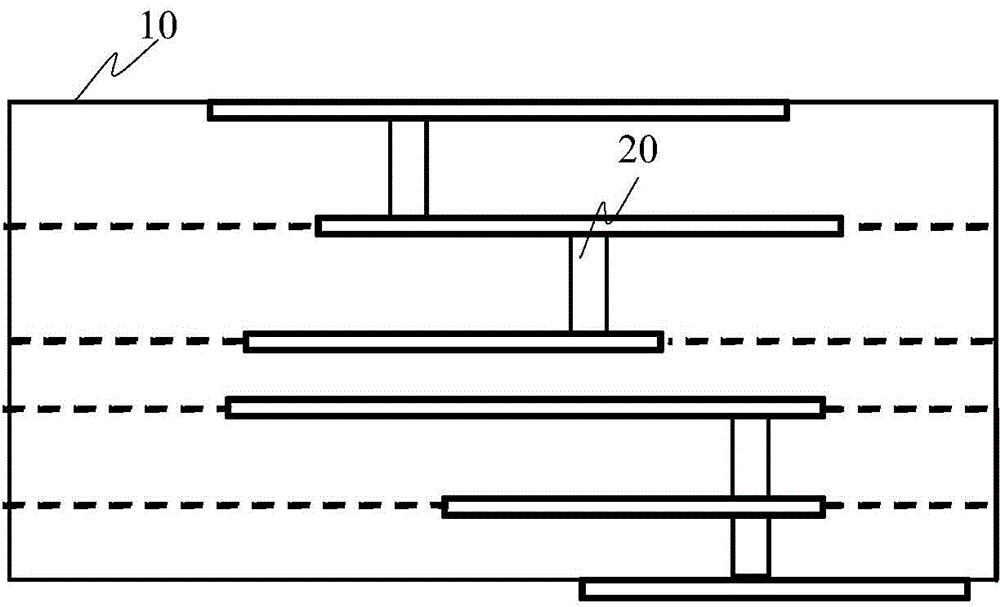

Grouted conductive gold paste applied to low-temperature co-fired ceramic and preparation method of grouted conductive gold paste

A technology of low-temperature co-fired ceramics and filling holes, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., and can solve problems such as the density of filling holes and unsatisfactory electrical conductivity. Achieve the effects of good filling hole density, excellent electrical conductivity, and simple method steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

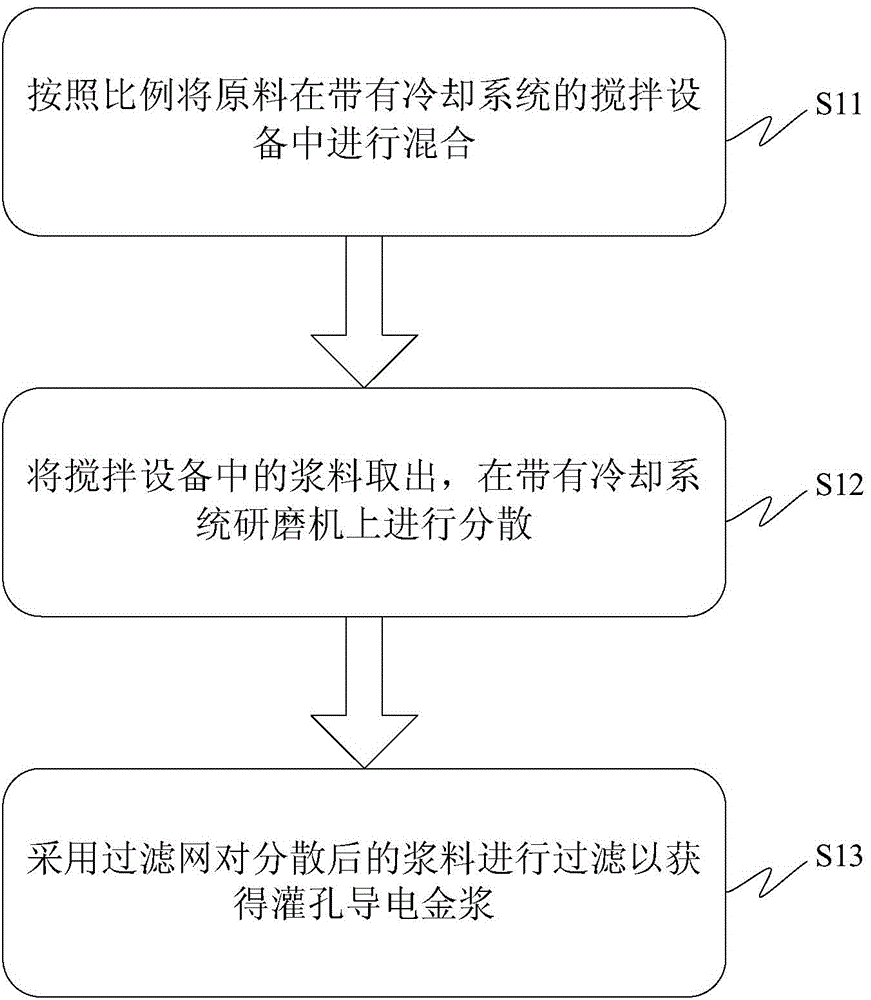

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a conductive gold paste for filling holes applied to low-temperature co-fired ceramics. The conductive gold paste for filling holes includes the following components in terms of mass ratio: 80% gold particles, 10% inorganic additives, 5% % carrier, 0.5% adjuvant, and 4.5% solvent.

[0030] As an example, the gold particles are selected from gold powders whose morphology is spherical and whose particle size is selected from gold powders whose D50 is between 1-3 microns and D90 is not greater than 5 microns.

[0031] As an example, the inorganic additives include the following components in parts by weight: 25 parts of Al 2 o 3 , 30 parts of SiO 2 , 10 copies of Bi 2 o 3 , 25 parts of CaCO 3 , and 10 parts of SrCaO 3 .

[0032] As an example, the carrier includes a mixture of the following components in mass ratio: 30% specialty resin, and 70% solvent. Further, the special resin is selected from esters, and the solvent is selected from alc...

Embodiment 2

[0041] This embodiment provides a conductive gold paste for filling holes applied to low-temperature co-fired ceramics. The conductive gold paste for filling holes includes the following components in terms of mass ratio: 95% gold particles, 1% inorganic additives, 1% % carrier, 0.3% adjuvant, and 2.7% solvent.

[0042] As an example, the gold particles are selected from gold powders whose morphology is flake-like, and whose particle size is selected from gold powder whose D50 is between 1-3 microns and whose D90 is not greater than 5 microns.

[0043] As an example, the inorganic additives include the following components in parts by weight: 20 parts of Al 2 o 3 , 35 parts of SiO 2, 10 copies of Bi 2 o 3 , 20 parts of CaCO 3 , and 15 parts of SrCaO 3 .

[0044] As an example, the carrier includes a mixture of the following components in mass ratio: 10% specialty resin, and 90% solvent. Further, the special resin is selected from alcohol esters, and the solvent is sele...

Embodiment 3

[0052] This embodiment provides a conductive gold paste for filling holes applied to low-temperature co-fired ceramics. The conductive gold paste for filling holes includes the following components in terms of mass ratio: 85% gold particles, 5% inorganic additives, 6 % carrier, 1% adjuvant, and 3% solvent.

[0053] As an example, the size of the gold particles is selected from gold powders whose D50 is between 1 and 3 microns and whose D90 is not greater than 5 microns.

[0054] As an example, the inorganic additives include the following components in parts by weight: 40 parts of Al 2 o 3 , 15 parts of SiO 2 , 35 copies of Bi 2 o 3 , 5 parts of CaCO 3 , and 5 parts of SrCaO 3 .

[0055] As an example, the carrier includes a mixture of the following components in mass ratio: 20% specialty resin, and 80% solvent. Further, the special resin is cellulose, and the solvent is alcohol.

[0056] As an example, the main and auxiliary components include a silane coupling agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com