External rotor motor

An external rotor motor and external rotor technology, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of affecting the stability of the motor and hindering the application , high noise and other issues, to achieve the effect of improving running stability, suppressing high-order harmonics, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

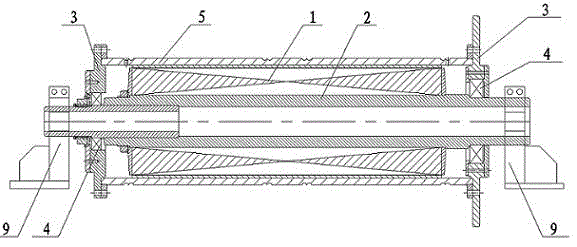

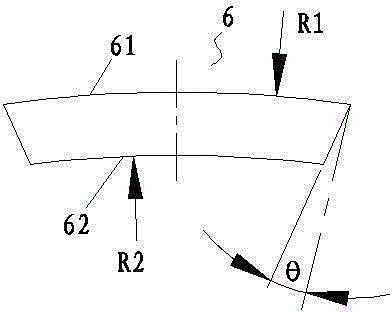

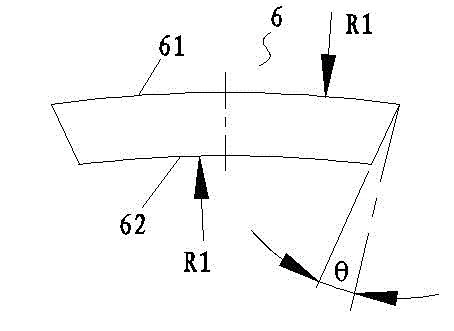

[0011] see Figure 1-5 , The outer rotor motor provided by the present invention includes an outer rotor and a stator 1 located inside the outer rotor, the stator is fixedly mounted on a central shaft 2, and the two ends of the central shaft are fixedly supported in two supports 9 respectively. The two ends of the outer rotor are fixedly connected with fixed discs 3, and the fixed discs are rotatably connected with the central shaft through rotor bearings 4. The outer rotor includes a cylindrical rotor housing 5, and the rotor housing is fixed with a There are several permanent magnets 6, and the several permanent magnets adopt the same tile-shaped hexahedron structure and are arranged regularly along the circumferential direction (direction along the circumference) and the axial direction (direction parallel to the axis of the central axis), any circumferential direction and The number of permanent magnets arranged in any axial direction is multiple, and the two circumferenti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Remanence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com