Fragrance composition for reducing lingering tobacco odor, and cigarette

A technology of composition and spices, which is applied in the field of cigarettes, and can solve problems affecting tobacco flavor, mixing, and restrictions on the types of spices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

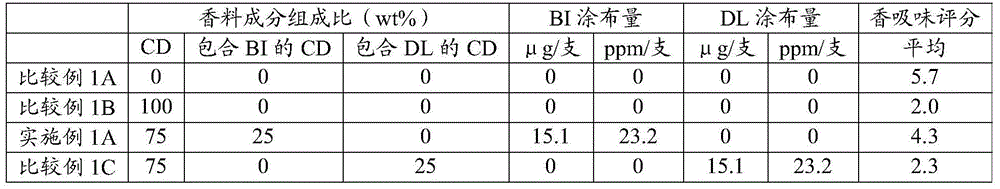

Embodiment 1A

[0022]Example 1A: 75 parts by weight of cyclodextrin (CD) and 25 parts by weight of cyclodextrin containing β-ionone (CD containing BI) were mixed in the form of powder. The mixed powder was dispersed so as to be 16 wt % with respect to a 6.0 wt % aqueous solution of carboxymethylcellulose to prepare a dispersion liquid. Using a gravure coater manufactured by Yashii Seiki Co., Ltd., the dispersion liquid was gravure-coated with a width of 7 mm on the center portion of a roll paper (P35) having a width of 27 mm. The cyclodextrin encapsulation rate of β-ionone was analyzed by GC-MSD, and the result was 9.2%, and the coating amount of β-ionone on the roll paper was 23.2ppm / branch. The cigarette samples of Example 1A were produced using the prepared rolling paper. As the cigarette, usual commercially available cigarettes were used.

[0023] Cigarette samples of Comparative Examples 1A, 1B, and 1C were prepared as controls for the cigarette samples of Example 1A. For the cigaret...

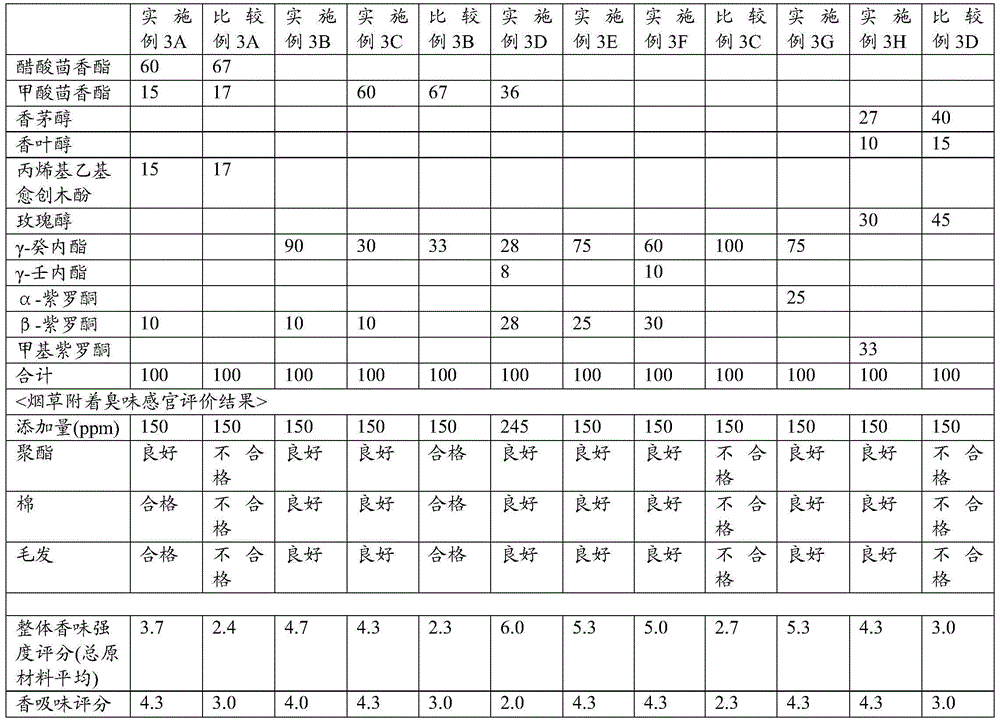

Embodiment 3A-3H and comparative example 3A-3D

[0052] After dissolving each flavor composition in ethanol, it was applied to the entire surface of the cigarette wrapping paper using a syringe. The application amount of the ethanol solution of each fragrance composition was 10 μL / cartridge. The added amount (ppm) in Table 3 represents the added amount of flavoring per one cigarette (650 mg shredded tobacco weight). For example, when the added amount is 150 ppm, 650 mg×150 ppm=97.5 μg of the fragrance composition is dissolved in 10 μL of the ethanol solution of the fragrance composition. Cigarettes were made using the prepared rolling paper, and sensory evaluation was carried out.

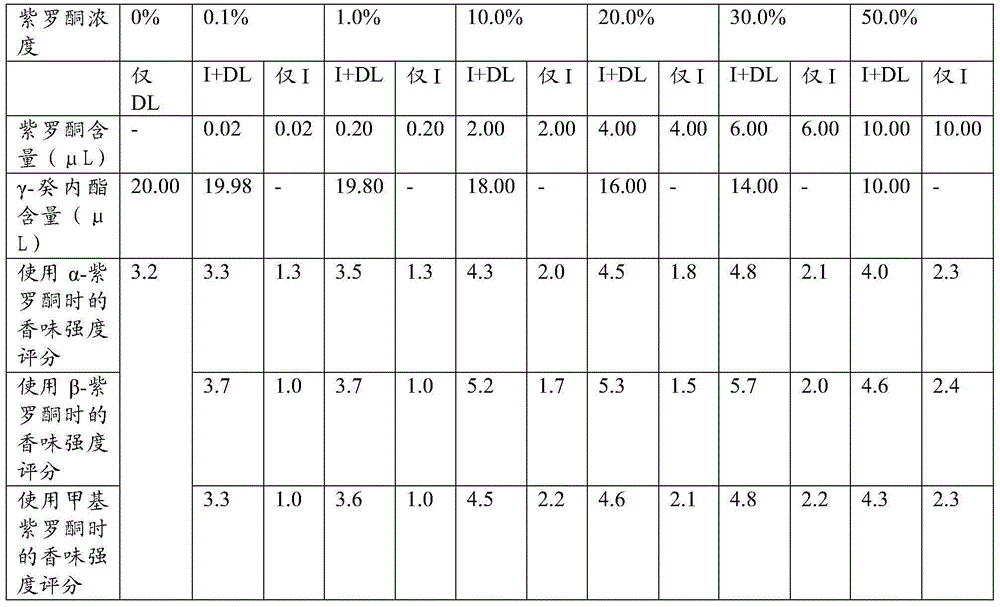

Embodiment 3I-3M

[0054] Each fragrance composition was clathrated with cyclodextrin. In the same manner as in Test 1, the fragrance-containing cyclodextrin was dissolved in a 6.0 wt % aqueous solution of carboxymethylcellulose to prepare a dispersion. The dispersion liquid was gravure coated with a width of 7 mm on the center portion of a cigarette paper having a width of 27 mm using a gravure coater. The addition amount (ppm) in Table 2 represents the addition amount of the fragrance composition, which is determined by the addition amount of cyclodextrin for inclusion of fragrance and the encapsulation efficiency of each fragrance composition. Cigarettes were made using the prepared rolling paper, and sensory evaluation was carried out.

[0055] [Sensory evaluation]

[0056] 1) Evaluation of Tobacco Adherence Odor

[0057] Smoke from burning cigarettes was made to adhere to polyester, cotton, and hair materials, and 48 professional evaluators in the company evaluated the odor of tobacco ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com