Efficient ribbon dispersion stirrer and ribbon dispersion stirring machine with same

A technology of dispersing stirring and mixer, which is applied to mixers with rotating stirring devices, mixer accessories, mixers, etc., which can solve the problems of low mixing efficiency, poor mixing effect, and inapplicability to high-viscosity materials, and achieve high mixing efficiency, The effect of good mixing effect and obvious mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

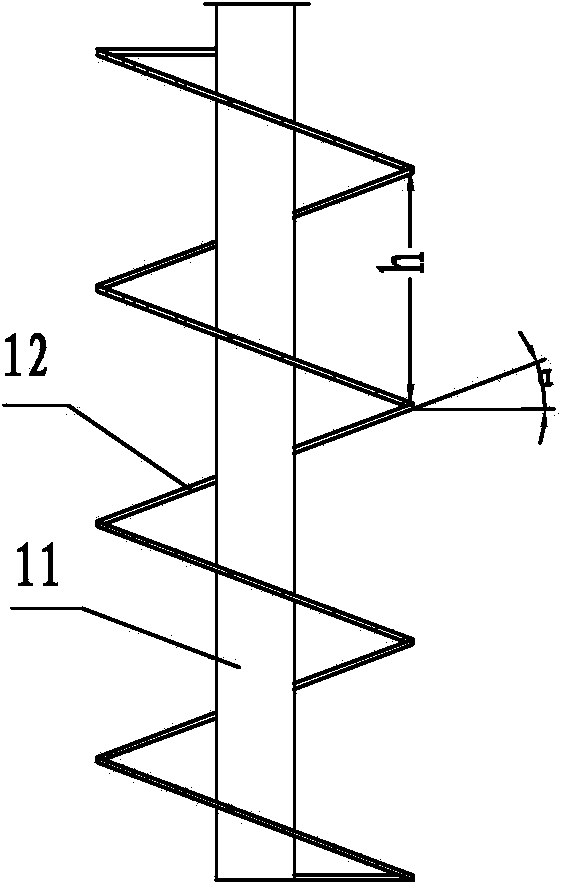

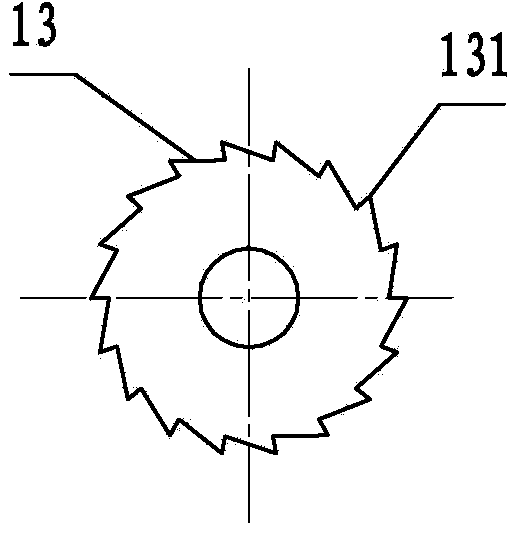

[0041] Embodiment one: if Figure 1-1-Figure 1-2 As shown, a high-efficiency screw dispersing mixer includes a rotating shaft 11 and 1-2 screw dispersing paddles installed on the rotating shaft, and the screw dispersing paddle is composed of a helical blade 12 and is arranged on Shaped paddle outer edge tooth piece 13 constitutes, and described helical blade inner edge is fixed on the rotating shaft, and described tooth piece is plane tooth piece 131, and plane tooth piece refers to this tooth piece and helical blade and The connecting parts of the tooth pieces are located in the same plane.

Embodiment 2

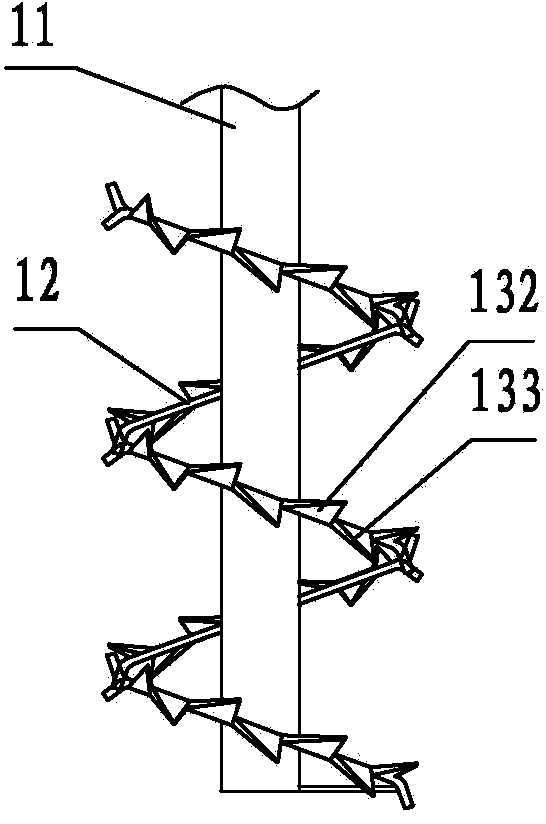

[0042] Embodiment two: if Figure 2-1-Figure 2-2 As shown, a high-efficiency screw dispersing mixer includes a rotating shaft 11 and 1-3 screw dispersing paddles installed on the rotating shaft, and the screw dispersing paddle is composed of a helical blade 12 and is arranged on The outer edge of the helical blade 13 is composed of the inner edge of the helical blade, and the inner edge of the helical blade is fixed on the rotating shaft. The tooth is composed of an upward tooth 132 and a downward tooth 133 arranged at intervals.

[0043] The helical blade 12 in this embodiment is a left helical blade formed by rotating clockwise. As a transformation of this embodiment, the helical blade can also be a right helical blade formed by counterclockwise rotation. leaves (such as Figure 3-1-Figure 3-2 shown).

[0044]The tooth piece that the present invention is arranged on the outer edge of the spiral blade can be a plane tooth piece 131 or / and an upward tooth piece 132 or / and a ...

Embodiment 3

[0048] Embodiment three: a kind of high-efficiency ribbon dispersing mixer, such as Figure 9 As shown, it includes agitator, beam I 22, motor I 24 fixed on beam I, lift cylinder 23 connected under beam I and oil station system 25 connected with lift cylinder. The high-efficiency ribbon dispersing mixer 1 The rotating shaft is installed on the beam I through the bearing housing 21 and the bearing, and the rotating shaft is connected with the motor I through a pulley and a belt. The agitator is the high-efficiency ribbon dispersing agitator 1 according to the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com