mobile loader

A loading and unloading machine, mobile technology, applied in storage devices, transportation and packaging, etc., can solve the problems of long operation time, low efficiency, high labor intensity, etc., and achieve the effect of improving work efficiency, reducing labor intensity and shortening operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

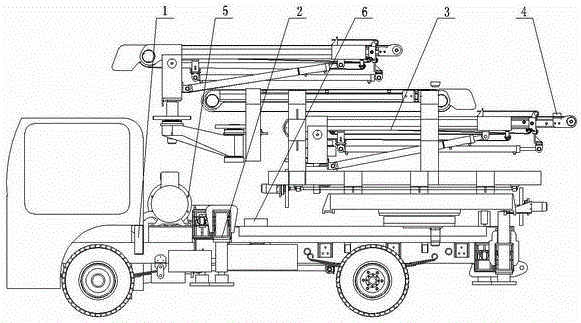

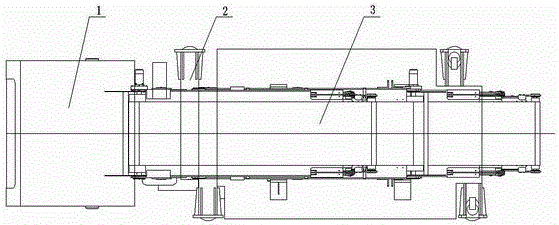

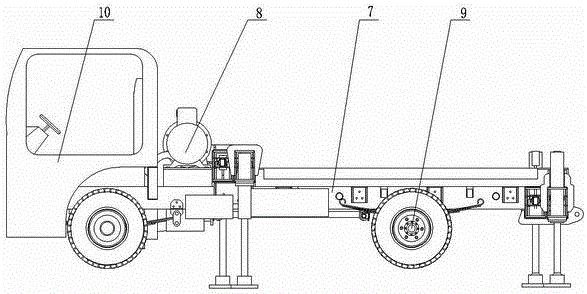

[0035] Such as figure 1 , figure 2 As shown, the mobile loading and unloading machine of the present invention is composed of six functional modules such as a vehicle chassis 1, a hydraulic support leg 2, a loading and unloading mechanism 3, a counting and printing system 4, a hydraulic system 5, and an electric control system 6. Integrating machinery, electricity, and hydraulic pressure as a whole, using its own diesel engine (it can also be equipped with an electric motor, using an external power supply) as the power, and through electrical, hydraulic, and mechanical transmission and control technologies, it drives the vehicle chassis 1 to walk, turn, brake, and drive. 1. The hydraulic outrigger 2 is extended and retracted and the loading and unloading mechanism 3 is expanded and retracted to meet the functional requirements of various working conditions and realize the driving and loading and unloading transportation operations of the whole machine. The vehicle chassis 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com