Disc-type micropore aerator

A technology of microporous aerators and aerators, which is applied in water aeration, chemical instruments and methods, sustainable biological treatment, etc., and can solve problems such as pollution of ventilation pipes

Inactive Publication Date: 2014-11-26

GUANGXI NANNING ZHONGJIA ENVIRONMENTAL PROTECTIONVALVE MFG

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The present invention is to overcome the technical defect that the ventilation pipe is polluted as the sewage enters the ventilation pipe in the above-mentioned prior art, and invents a disc-type microporous aerator

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0021] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

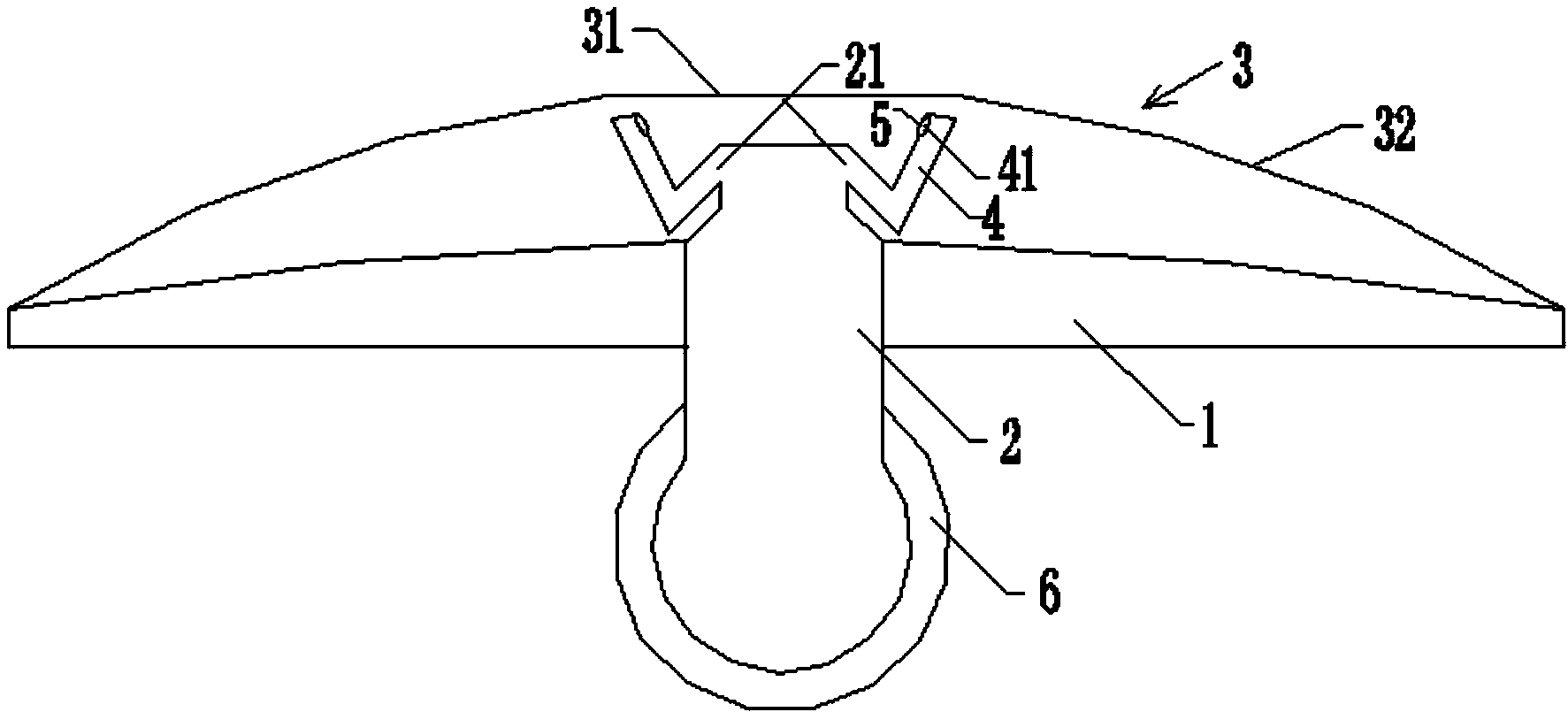

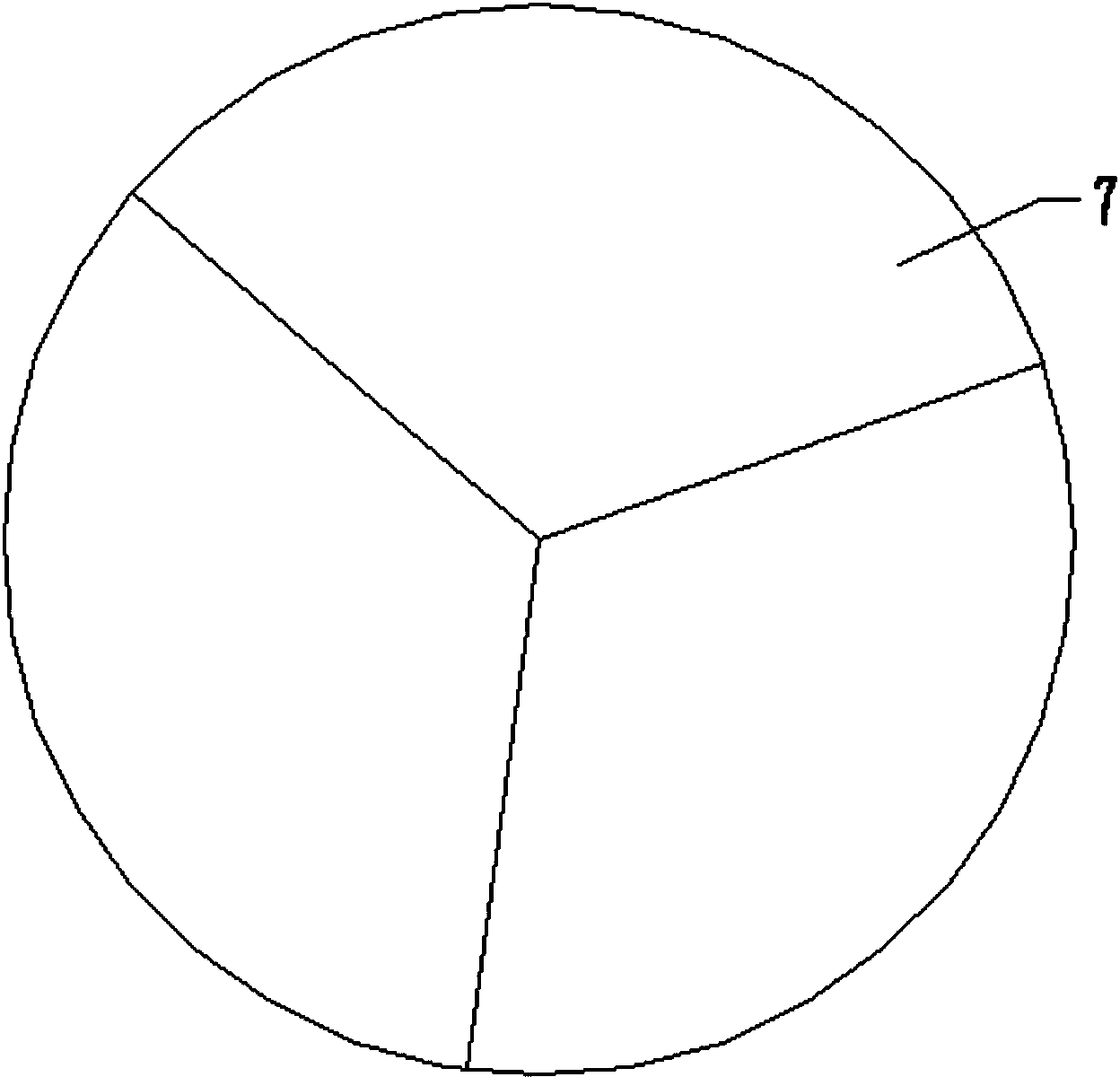

The invention discloses a disc-type micropore aerator including a flow guide disc, a rubber membrane sheet and a plurality of gas guide pipes; the middle part of the flow guide disc is provided with a hollow flow guide pipe protruding out of the upper surface of the flow guide disc, the end part of the upper end of the flow guide disc is in a sealing state, and the side wall surface of the upper end is provided with a plurality of gas guide holes; the central area of the rubber membrane sheet is a non-pore area, and the periphery area is provided with a plurality of micropores penetrating through the rubber membrane sheet; the rubber membrane sheet is positioned above the flow guide disc, the periphery edge of the rubber membrane sheet and the periphery edge of the flow guide disc are in sealing connection, and a gas guide cavity is formed between the flow guide disc and the rubber membrane sheet; the plurality of gas guide pipes are each of an V shape, one end of each of the plurality of gas guide pipes is connected with one of the plurality of gas guide holes, the side wall of the other end of each of the plurality of gas guide pipes is provided with a gas outlet hole, the gas outlet direction is that a gas flow sprays to a part of the central area of the rubber membrane sheet, and the gas outlet holes are each provided with a non-return valve. The device cannot cause pollution of ventilation pipelines.

Description

technical field [0001] The invention relates to the field of sewage treatment equipment, in particular to a disc microporous aerator. Background technique [0002] Among the many methods of sewage treatment, aerobic biological treatment is an economical and effective method. There are many factors that affect the effect of aerobic biological treatment. One of the important factors is that there must be sufficient dissolved oxygen in sewage, aeration The device is a key device for supplying oxygen to sewage. [0003] And in existing microporous aerator, the pipeline that carries out ventilation is generally designed bigger, although check valve has been arranged in the device, still have sewage to carry out to ventilation pipeline in the moment that check valve is closed, like this, along with The accumulation of sewage in the ventilation pipe will cause the pollution of the ventilation pipe. Contents of the invention [0004] The present invention aims to overcome the te...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F3/02C02F7/00

CPCY02W10/10

Inventor 林天祥蔡子才林斌铨谢章志蔡永远李远知

Owner GUANGXI NANNING ZHONGJIA ENVIRONMENTAL PROTECTIONVALVE MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com