Scrap tire boulevard

A technology for waste tires and avenues, applied in container cultivation, horticulture, botany equipment and methods, etc., can solve the problems of not making full use of the elasticity and support of waste tires, no environmental protection, energy saving, high efficiency, low cost, unfavorable promotion and use, etc. problems, to achieve the effect of improving mechanical properties, stable and reliable structure, and not easy to lose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

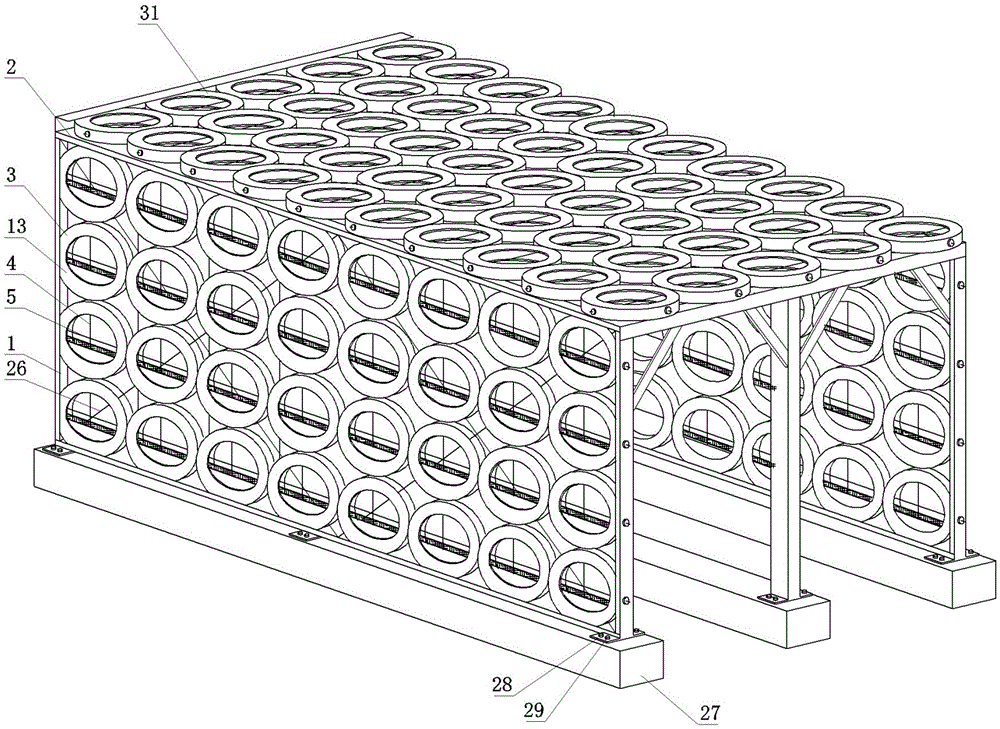

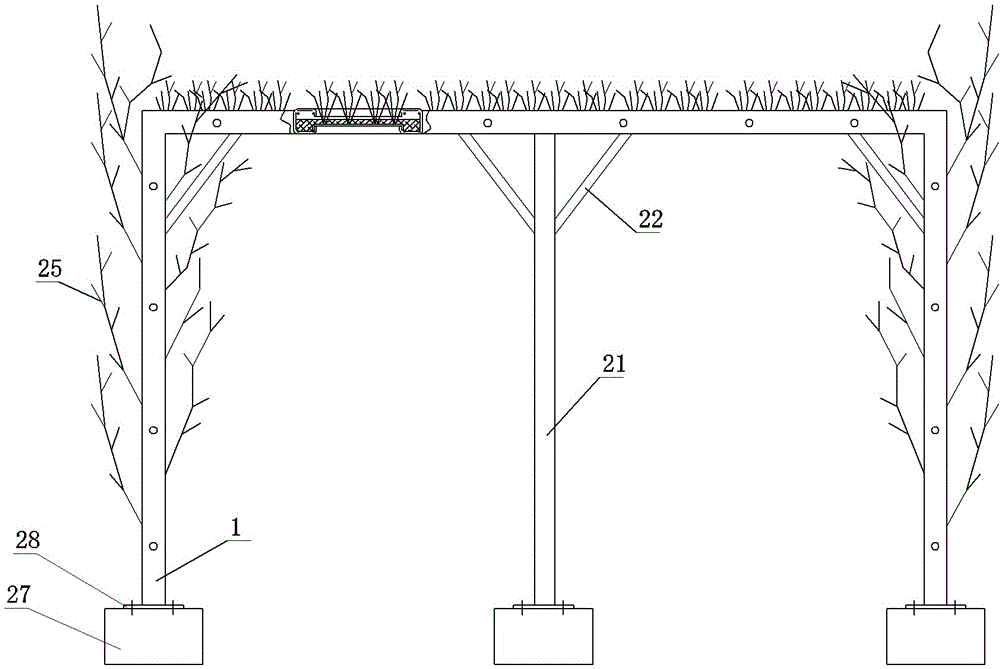

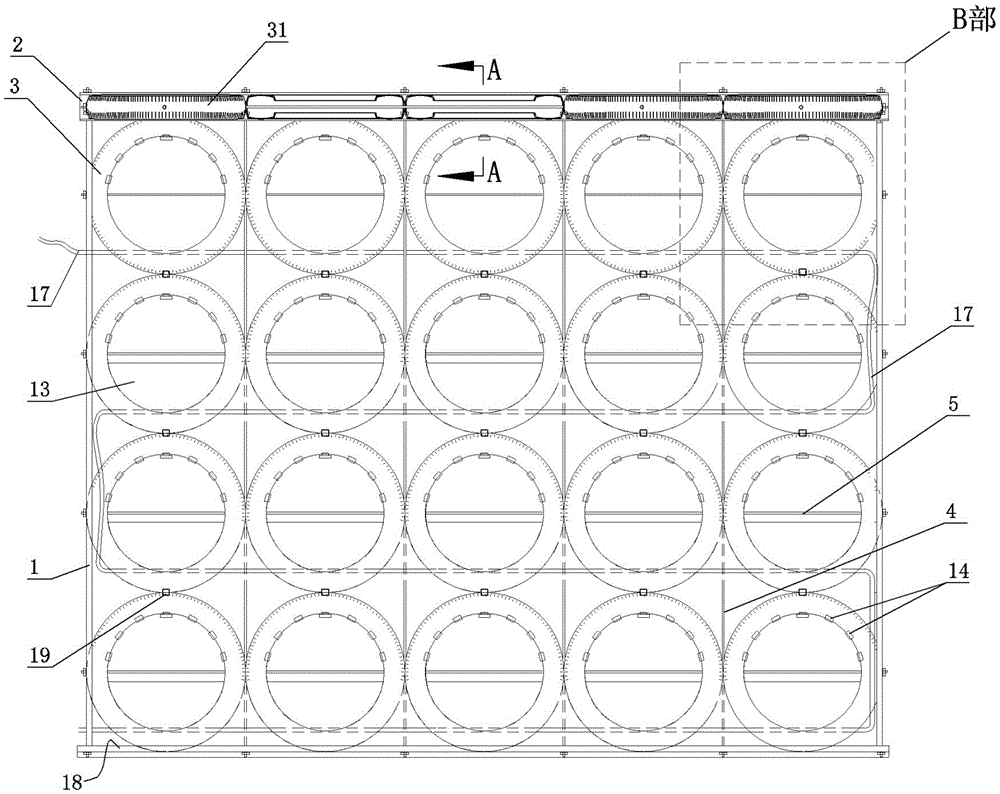

[0024] Embodiment 1: a kind of waste tire boulevard, see figure 1 , figure 2 and image 3 , the channel structure composed of the left and right fences and the ceiling, the lower ends of the left and right fences are respectively provided with concrete bottom beams, the lower ends of the left and right fences are fixed on the concrete bottom beams through the bottom plate and anchor bolts, and the left and right fences include The outer frame, waste tires and steel strands are fully filled with waste tires adjacent to each other in the outer frame to form the main body of the fence. The outer frame includes left and right sides 1, a top beam 2 and a bottom beam. The outer frame is adjustable in length and width, see the specific structure Figure 5 and Figure 6 , Adjusting structures are arranged between the top beam 2 and the bottom beam and the side 1 respectively. The upper and lower ends of the side are respectively provided with a frame adjustment rod 16 and a fram...

Embodiment 2

[0029] Embodiment 2: another kind of waste tire boulevard, see Figure 7 , the content is basically the same as that of Embodiment 1, except that the roof of the boulevard is a truss structure 24, and the creeping plants planted in the fences on both sides can be wound and covered on the upper side of the ceiling to form a green boulevard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com