Drilling tool combining long spiral drill rod with down-hole hammer

A down-the-hole hammer and long helix technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of large mechanical equipment and labor force, and achieve the effect of compact structure, simple structure and great implementation value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

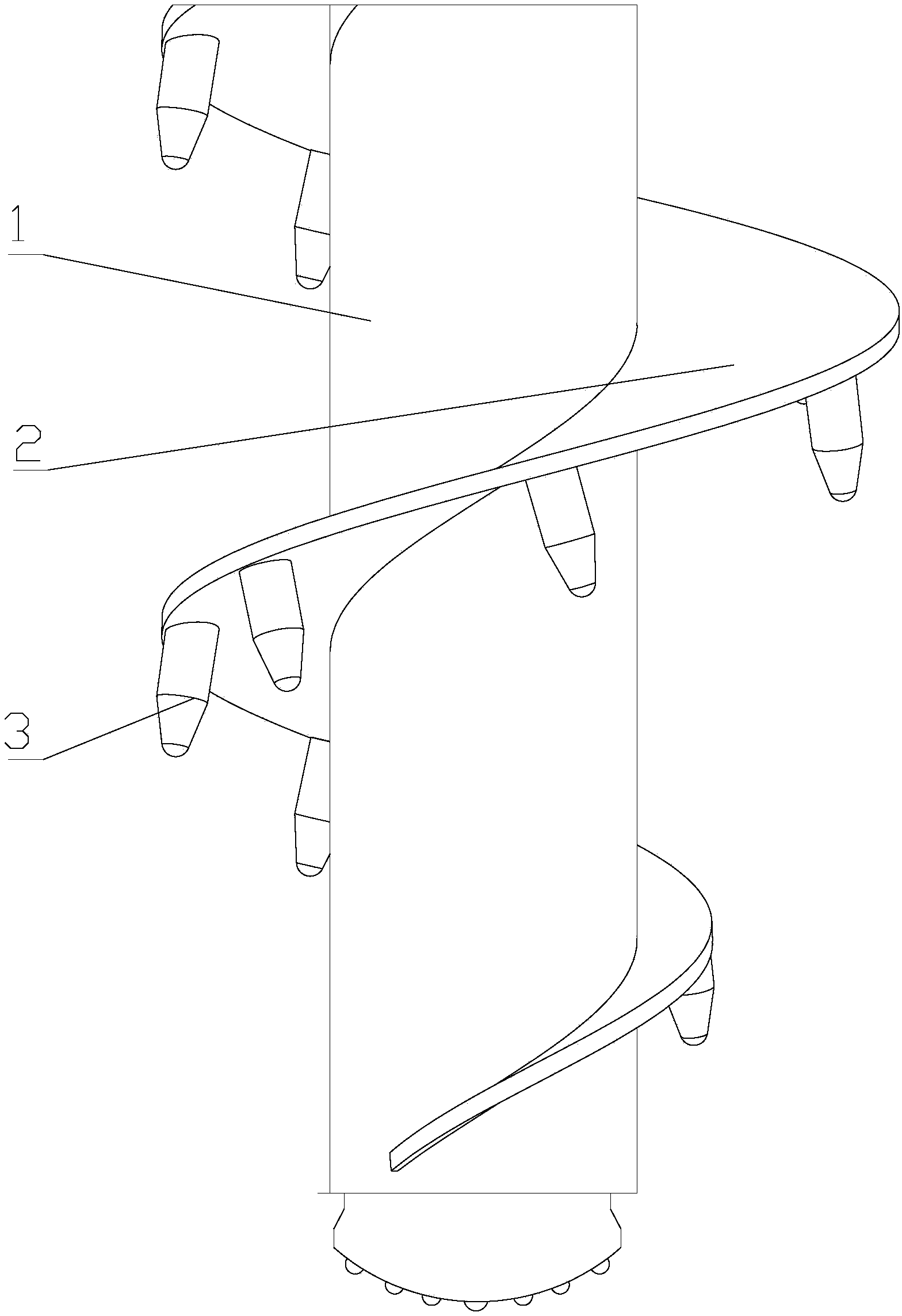

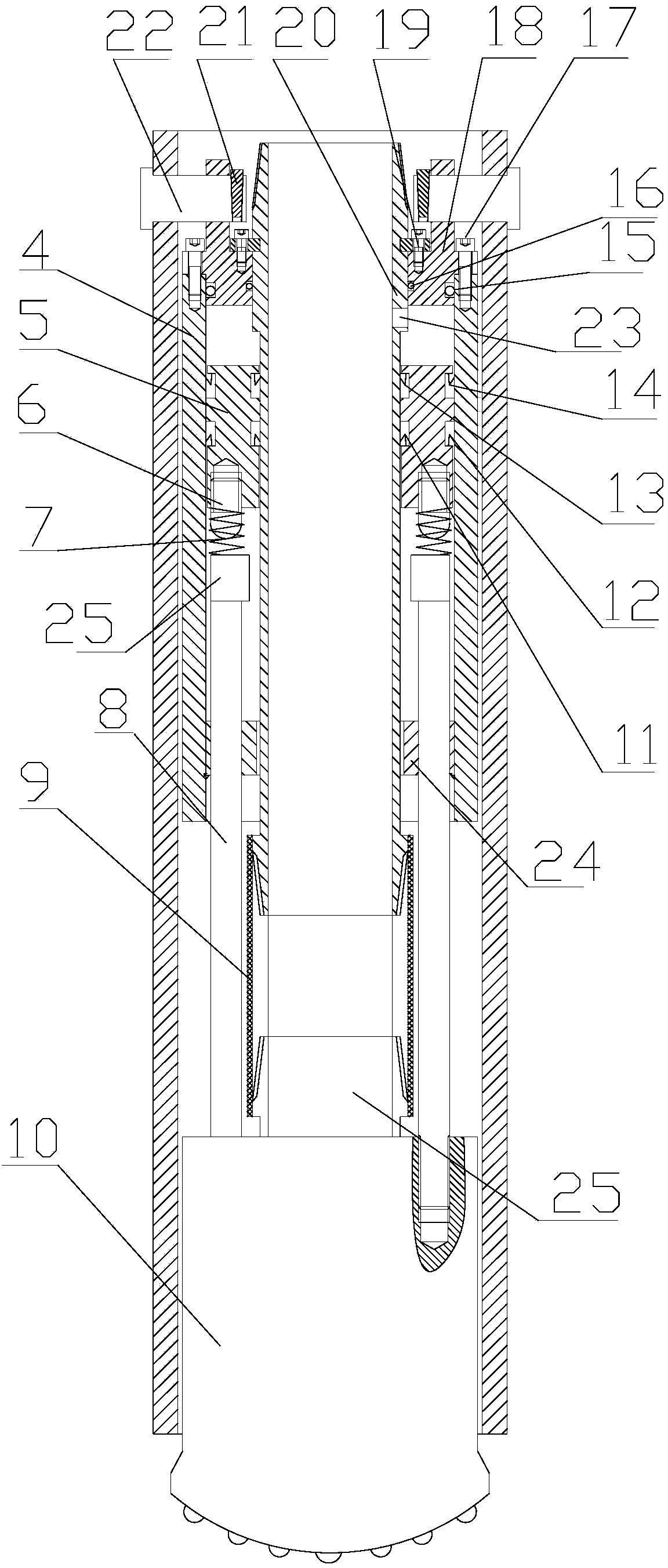

[0023] Referring to the accompanying drawings, a drilling tool combined with a long helical drill rod and a down-the-hole hammer includes a drill rod 1 and a helical blade 2 that spirally surrounds the drill rod. Drill bit 10, the upper part is provided with the propulsion mechanism of described down-the-hole hammer 10;

[0024] The propulsion mechanism includes a cylinder 4 fixed on the drill rod 1, a vent pipe 20 longitudinally runs through the cylinder 4 and the piston 5 in the cylinder 4, and the inlet end of the vent pipe 20 is connected with an external air intake device, so The side wall of the air pipe 20 is provided with a first air outlet 23 for feeding the cylinder cavity between the cylinder end cover 18 and the piston 5, and the inner wall of the cylinder 4 and the outer wall of the air pipe 20 form a piston. 5, the bottom end of the piston 5 is connected with the ejector rod 6 for pushing the down-the-hole hammer 10, the ejector rod 6 is connected with the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com