A coal-fired heating furnace for civil use

A heating furnace and coal-burning technology, which is used in household stoves/stoves, applications, household heating, etc., can solve the problems of insufficient heat exchange, large heating costs, and low efficiency, saving coal resources and improving heat utilization. , the effect of avoiding heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

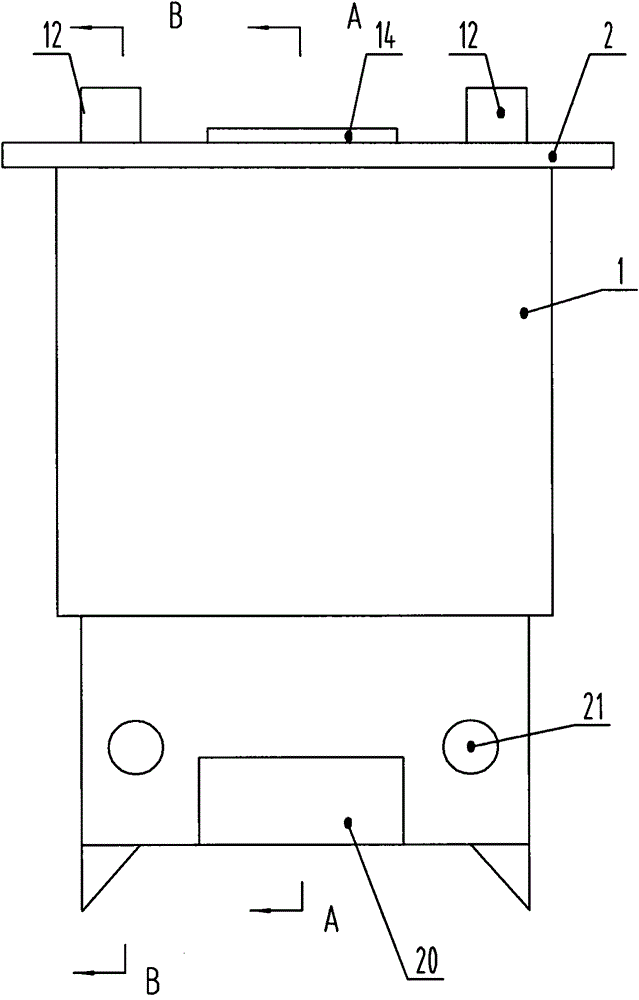

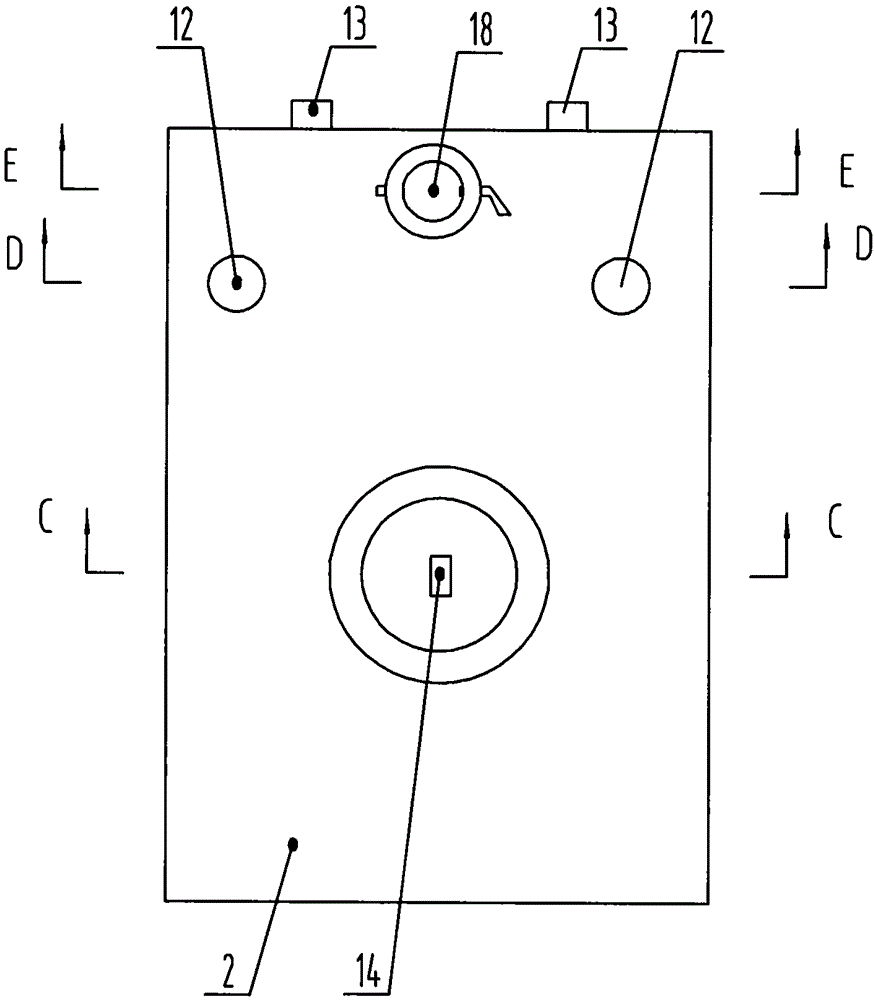

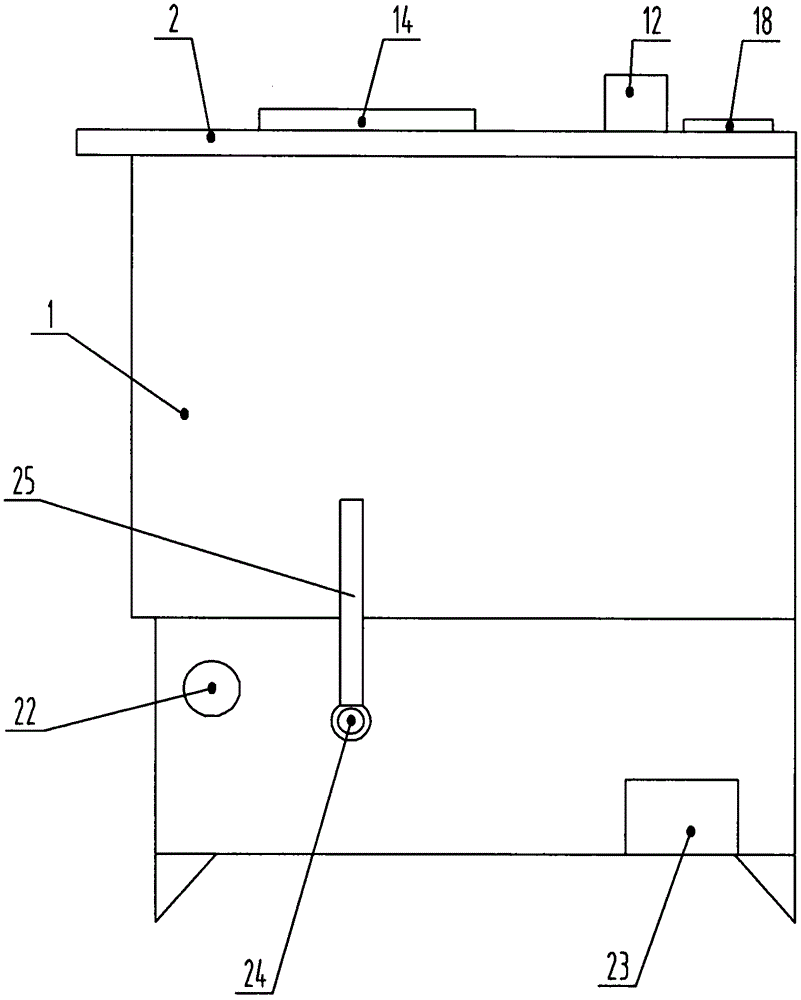

[0038] See Figure 1-2 , 4-8, 10-11, in the figure (the direction of the arrow indicates the flow of flue gas), the civil coal-fired heating stove of the present invention includes a furnace shell 1 and a top cover 2. The lower part of the sealed chamber formed by the furnace shell is Furnace 3, a grate 4 is provided in the furnace, the middle of the top cover is provided with a coal filling port, and the upper part of the sealed chamber is provided with box-shaped inner and outer water jackets 5, 6 with open lower ends, wherein the top of the inner water jacket To be lower than the top of the outer water jacket, one side of the inner and outer water jackets is connected by a pipe 7. The tops of the inner and outer water jackets are provided with through holes 8, 9 respectively at the coal filling openings, and the lower end of the inner water jacket is fixed to the furnace On the bent frame, the top of the outer water jacket is fixed on the bottom surface of the top cover, the ...

Embodiment 2

[0041] See Figure 5-11 The structure of this embodiment is similar to that of the first embodiment, and the same parts will not be repeated here. The difference is that: the inner wall of the housing described in this embodiment is provided with a heat insulation layer 15. A heat preservation channel 16 is provided between the shell and the heat insulation layer, and the width of the heat preservation channel is 25 mm.

[0042] Compared with the first embodiment, this embodiment can avoid the loss of heat generated by combustion as much as possible during use, and improve the heat utilization rate; moreover, in this way, no matter how the boiler is burned, the outer wall is cool to the touch, which also ensures It is safe to use and prevents children from being burned by accidentally touching the furnace body.

Embodiment 3

[0044] See figure 2 , 5 , 9, 11-12, the structure of this embodiment is similar to the first embodiment, and the same parts will not be repeated here. The difference is: in this embodiment, there is provided between the rear side of the outer water jacket and the furnace shell The smoke exhaust channel 17 has a smoke exhaust port on the top cover corresponding to the smoke exhaust channel. A blocking cover 18 is provided in the smoke exhaust port, two sides of the blocking cover are pivotally hinged on the smoke exhaust port, and a rotating handle 19 is provided on one side of the blocking cover.

[0045] This embodiment is compared with the first embodiment. When in use, because the smoke exhaust channel is set between the rear side of the outer water jacket and the furnace shell, the smoke will be reheated by the outer water jacket through the coal fire secondary circulation channel. The residual heat contained in the gas is already very small, and the exhausted smoke is almos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com