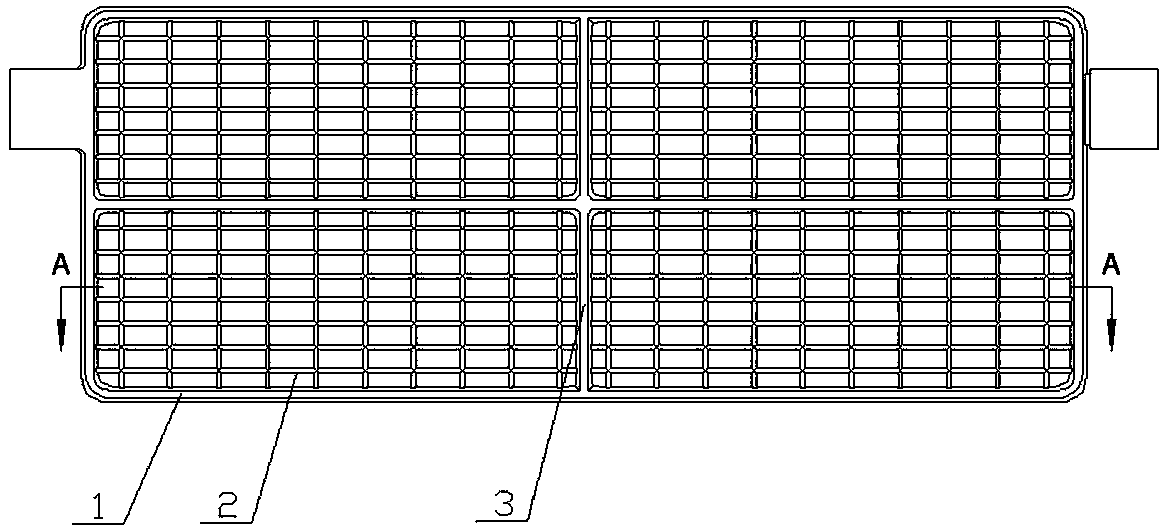

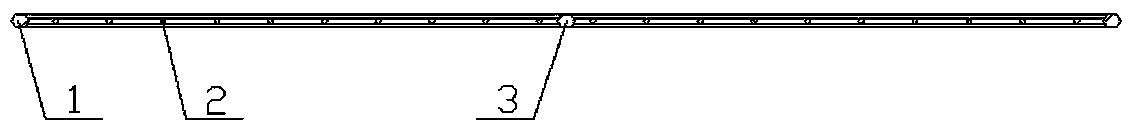

Lead-acid battery grid structure

A lead-acid battery and grid technology, applied in the direction of electrode carrier/collector, etc., can solve the problems of battery capacity attenuation, battery compression ratio drop, large internal rib spacing, etc., achieve good plate consistency and improve battery performance , The effect of uniform plate thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] see figure 1 , figure 2 , the inner ribs 2 in the grid are thin and dense, the inner ribs are cylindrical, and their diameter is 1 / 2 of the thickness of the outer frame 1. In this example, the distance between the inner ribs is 10mm, and the diameter of the inner ribs is 2mm. The inside of the outer frame is provided with longitudinal and transverse thick ribs 3, and the thickness of the thick ribs is consistent with the thickness of the outer frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com