Bus fixed contact grounding device for KYN28 type switch cabinet

A technology of grounding device and static contact, which is applied in the direction of switchgear, electrical connection seat, clip connection conductor connection, etc. It can solve the problems of personal safety hazards, equipment damage, and the inability to ensure the safety of bus power failure, so as to improve safety. and efficiency, protection of life safety, fast and convenient connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

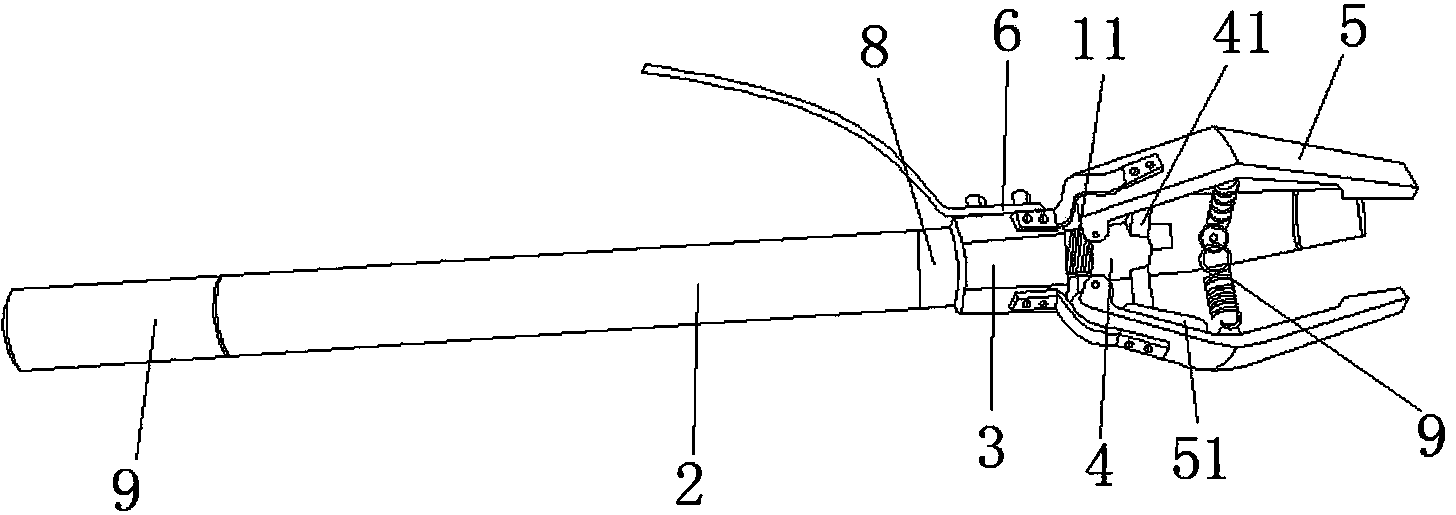

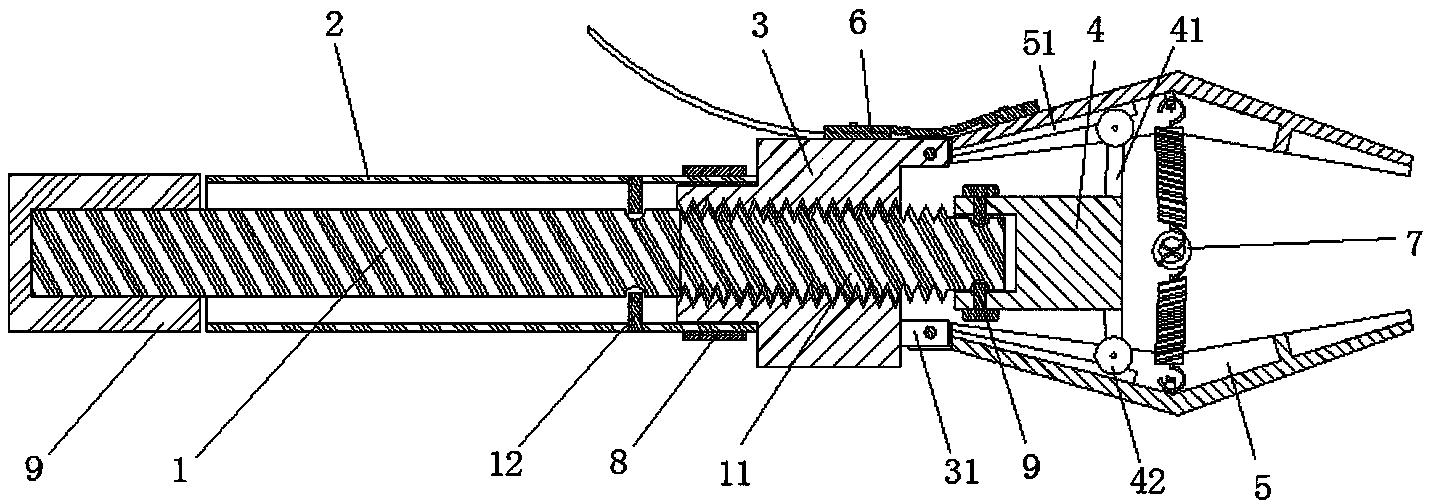

[0026] Figure 1 and figure 2 As shown, a KYN28 type switchgear busbar static contact grounding device includes an insulating material operating rod 1, an insulating material operating rod sleeve 2, a metal base 3, a push rod 4, and three metal claws 5. The lead wire 6 and the tightening device 7, the joystick 1 is cylindrical, the head of the joystick 1 is provided with a screw 11, the outer wall of the upper part of the base 3 is a regular hexagon, and the outer wall of the lower part is a cylinder Three claw seats 31 are evenly arranged around the axis of the base 3 on the edge of the upper top surface of the outer wall, and the claw seats 31 are arranged in a ring around the axis of the through hole. The inner wall of the hole is provided with a wire, the screw 11 on the top of the operating rod 1 matches the wire inside the base 3, the operating rod 1 moves up and down inside the base 3 through rotation, and the outer part of the operating rod 1 is covered with an operati...

Embodiment 2

[0028] Other technical features of the equipment in this implementation are the same as those in Example 1, except that the connection between the screw rod and the ejector rod is changed to the following structure: the bottom of the ejector rod is provided with a hollow annular base, and the inner wall of the ejector rod is connected to the wire Bearings are arranged between the outer walls of the rods, thereby reducing the steps of digging and screw holes, and the stability of the bearings is also higher, which can prolong the service life of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com