Motor system and electric vehicle

A technology for electric vehicles and motor shafts, applied in electric vehicles, motors, electric components, etc., can solve the problems of current loss, poor heat dissipation, low work efficiency, etc., to improve the response speed, reduce current loss, and good waterproof performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

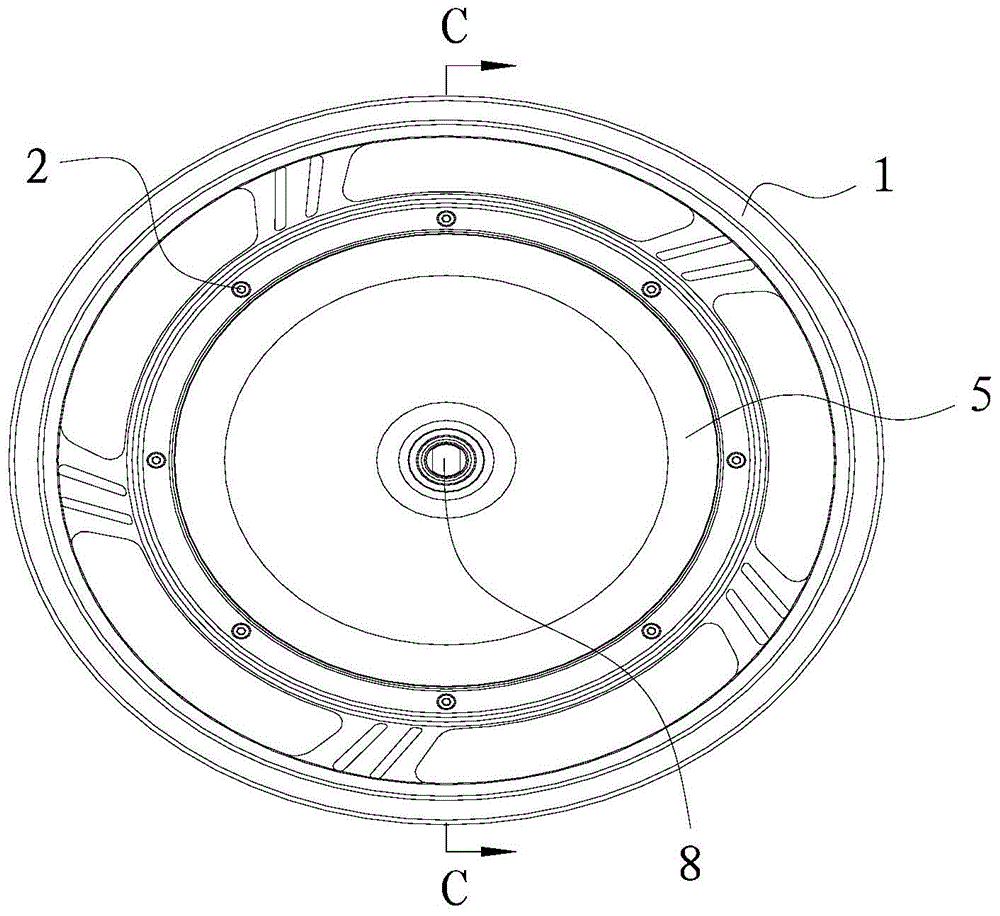

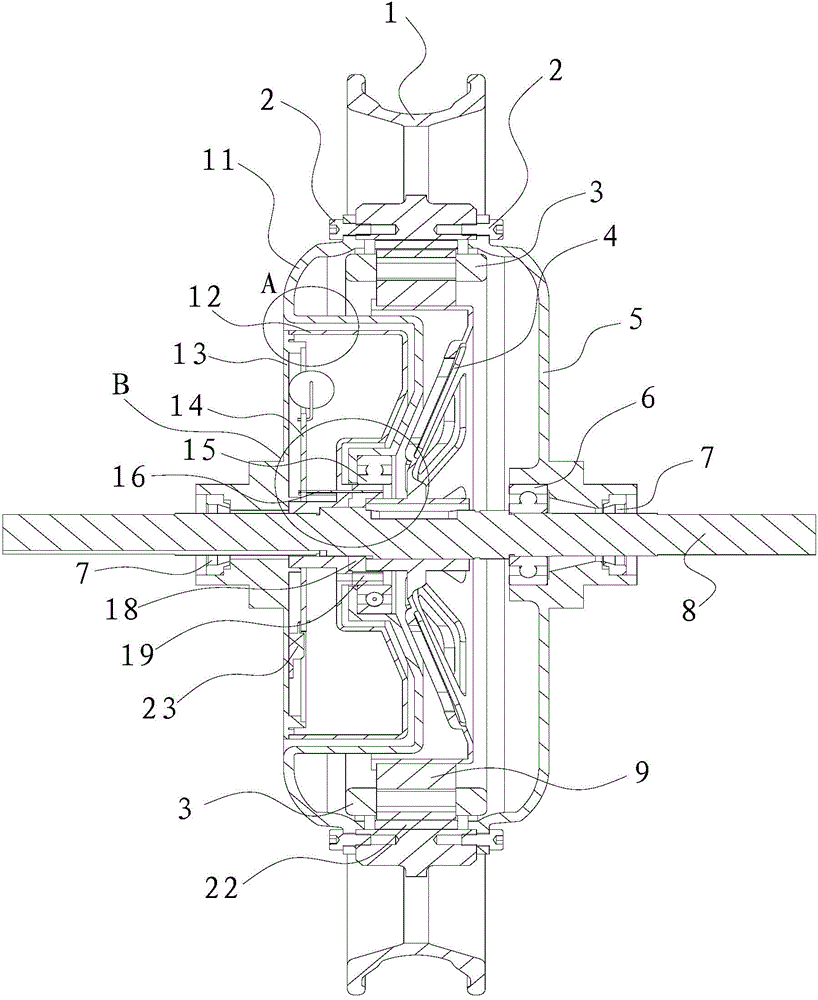

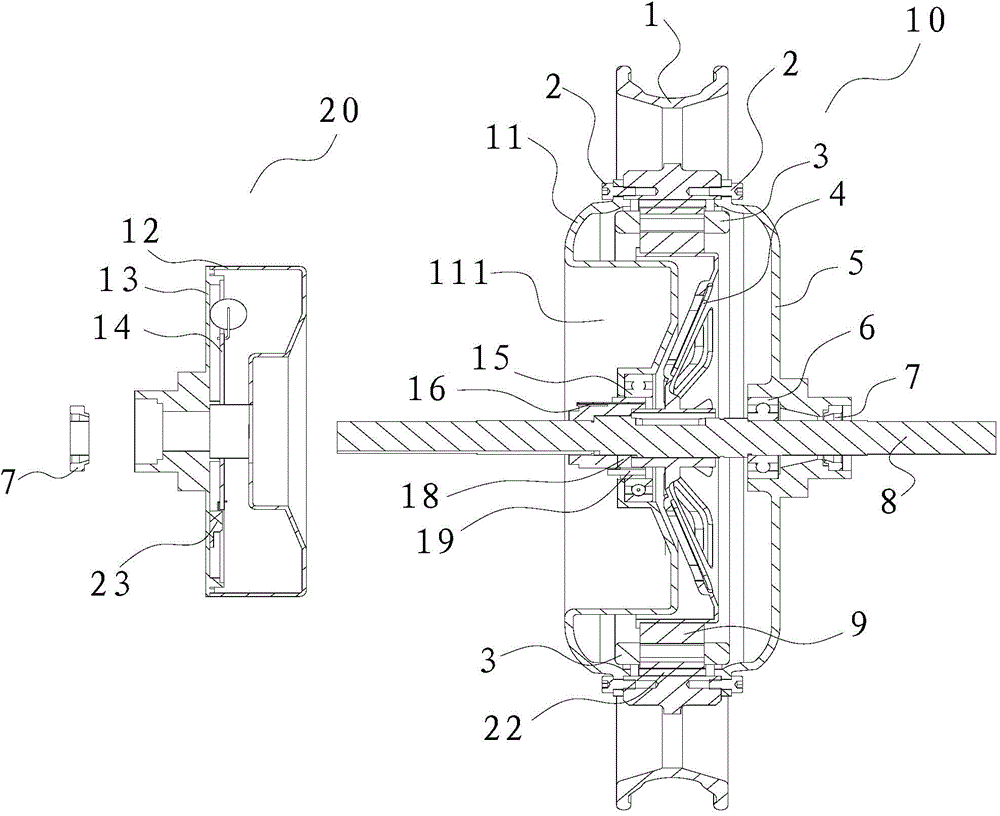

[0029] This preferred embodiment provides a motor system. like Figure 1 to Figure 5 As shown, the motor system includes a motor 10 and a controller 20 , and a connector 18 is provided between the motor 10 and the controller 20 . The motor 10 includes two side covers, wherein the first side cover 11 is recessed inward to form a recess 111 . The motor shaft 8 of the motor 10 passes through the recess 111 ; the controller 20 is mounted on the motor shaft 8 and located in the recess 111 .

[0030] The controller 20 is set in the concave portion 111 formed by the recessed side cover of the motor 10, and then connected through the connector 18, which shortens or even cancels the connection line originally connected between the controller 20 and the motor 10, reduces current consumption, and improves The reaction speed of the control signal is improved; the risk of water seepage into the motor 10 from the position of the connection hole is reduced; the space of the whole vehicle i...

Embodiment 2

[0038] This preferred embodiment provides a motor system whose structure is basically the same as that of the first preferred embodiment. The motor system includes a motor and a controller, a connector is provided between the motor and the controller, the motor includes two side covers, wherein the first side cover is recessed inward to form a recess, and the motor shaft of the motor passes through the recess; the controller is installed on on the motor shaft and located in the recess.

[0039] The difference is that a gap can be formed between the controller shell and the outer side wall of the recess, and they can also be close together, which does not affect the invention purpose of shortening or even canceling the connection and reducing the current consumption. The MOSFET and the PCB board can be arranged in parallel or vertically, as long as the internal space of the controller can accommodate the MOSFET. The MOSFET can be placed on the inner wall of the side cover of t...

Embodiment 3

[0041] This preferred embodiment provides an electric vehicle, which is provided with the motor system as described in the first or second preferred embodiment. The setting position of the motor system is not limited, and it can be set on the vehicle frame of the electric vehicle, and can also be set on the driving wheel of the electric vehicle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com