Triangular end positive electrode plate of wet type electric dust remover

A wet electrostatic precipitator and anode plate technology, applied in the direction of electrode structure, external electrostatic separator, electrostatic separation, etc., can solve the problems of destroying the formation of water film of anode plate, large plate end structure, and small surface of dust collecting plate. , to achieve the effect of increasing the area of the dust collector, improving the spacing between the cathode and anode, and maintaining the spacing between the cathode and anode.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

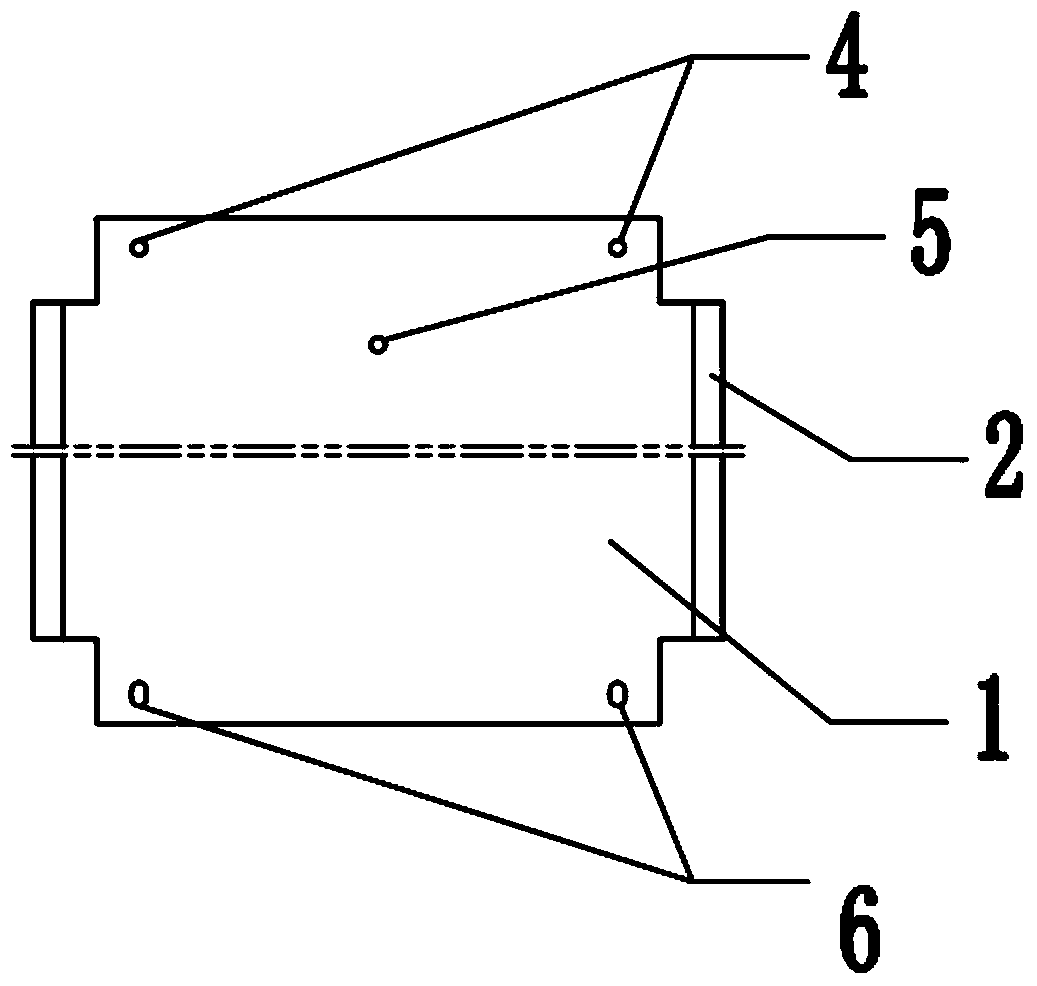

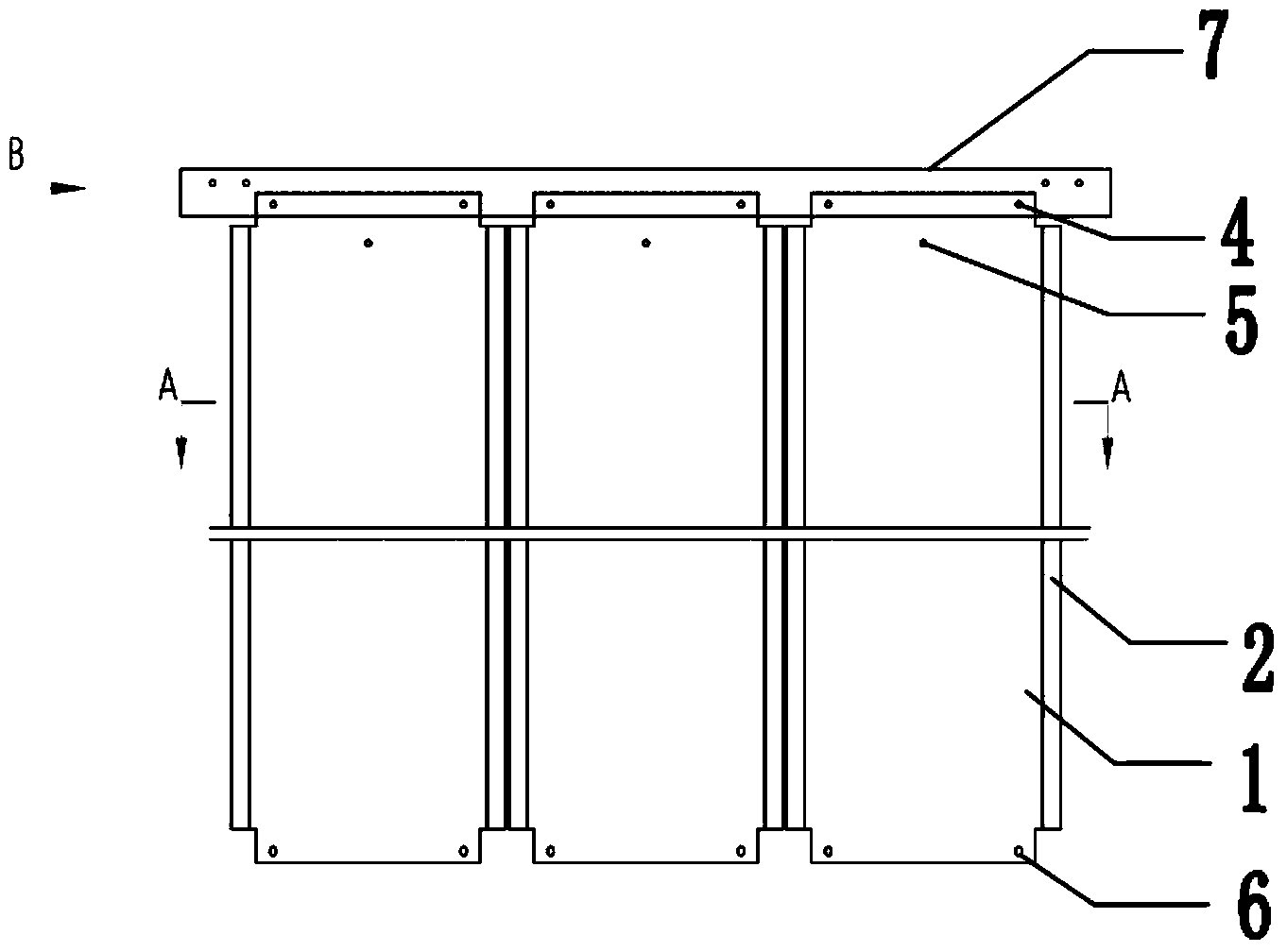

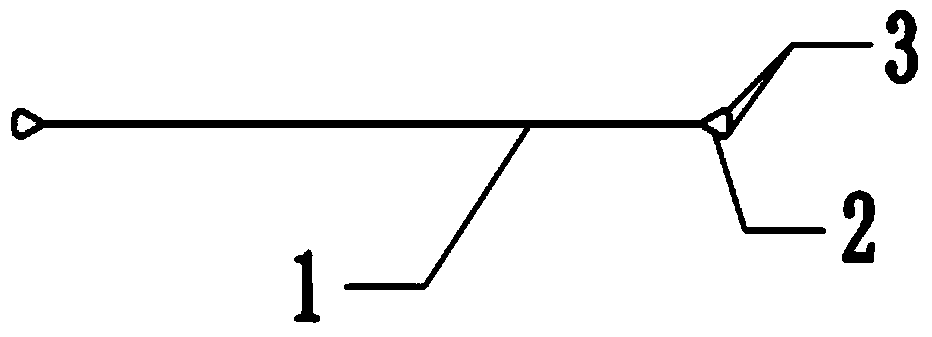

[0029] see Figure 1-5 , the anode plate 1 adopts a flat structure, and no groove is pressed against the plate, which is beneficial to the formation of a flat water film. The anode plate 1 has a width of 818mm and a length of 12m. The material of the anode plate is 2205 stainless steel. The curved edges on both sides of the anode plate 1 adopt a triangular end structure 2, and the two corners of the bottom edge of the triangle adopt a design of circular arc corners 3, which can effectively avoid creepage at the sharp corners of the triangular end. The triangular end structure strengthens the main body of the plate and prevents the plate from bending and deforming. This structure has better strength than other structures. Especially suitable for long anode plates.

[0030] see Figure 4 , the two sides of the triangular end structure of the end structure 2 are linear. This structure is simple to manufacture and more compact than other structures in the past. Under the same...

Embodiment ( 2

[0034] The difference between this embodiment and embodiment (1) is: see Figure 5 The two sides of the generally triangular end structure 2 are designed with arc lines, which can effectively avoid the generation of sharp corners at the end, and can also effectively avoid creepage at the sharp corners of the triangular end. The plate material is SUS316L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com