Gem faceting machine

A faceting and gemstone technology, applied in machine tools, grinding machines, metal processing equipment and other directions suitable for grinding the edge of workpieces, can solve the problems of large vibration, difficult to control processing accuracy, poor quality, etc. The effect of guaranteeing precision and improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

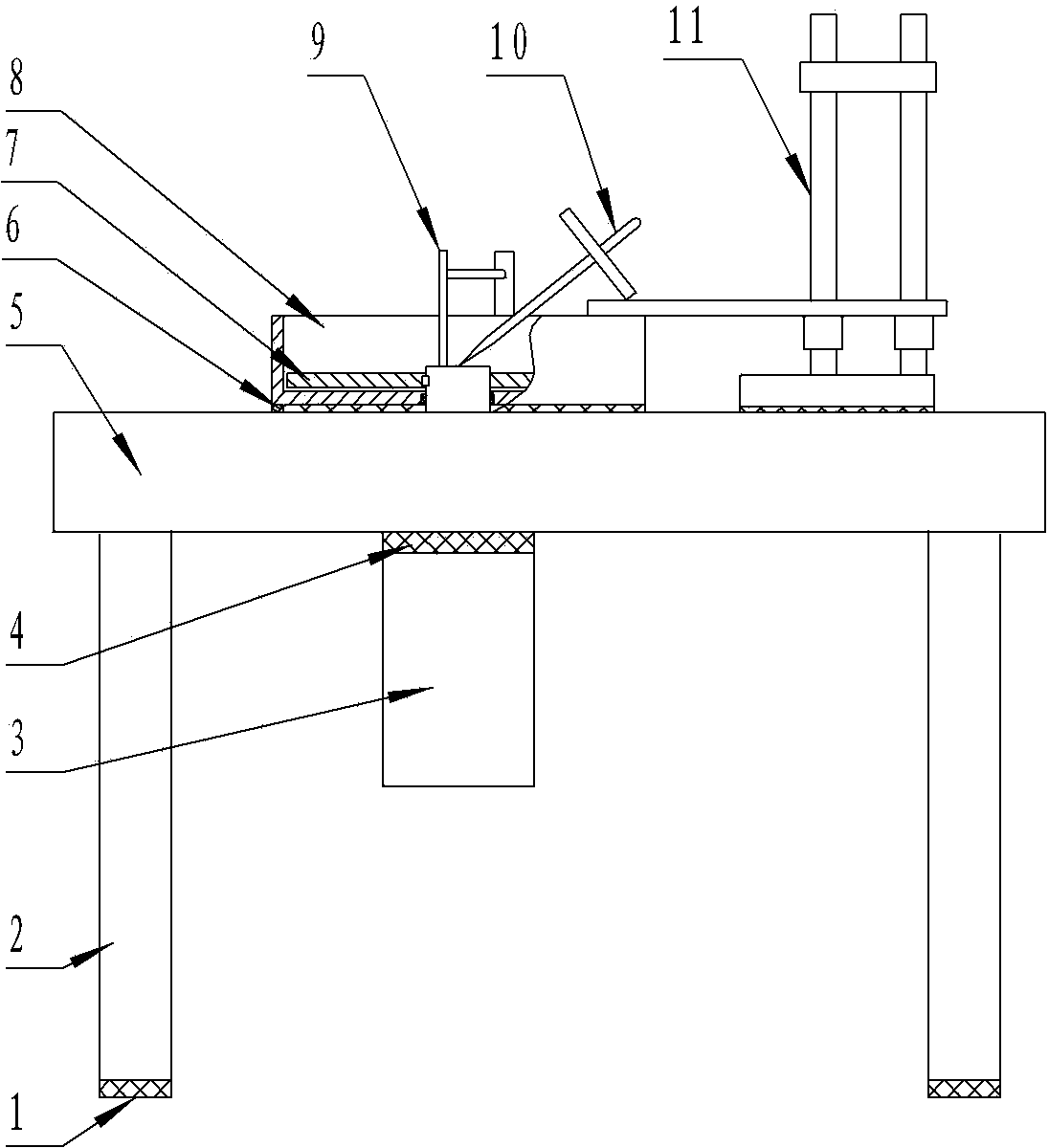

[0010] like figure 1 The gemstone faceting machine shown, it comprises the workbench 5 that has support foot 2, is provided with motor 3 vertically under workbench 5, and the output shaft of motor 3 passes through workbench 5 upwards, and the output shaft of motor 3 is in the workbench The part on the platform 5 is equipped with a disc 8 with an upwardly protruding edge, and the part of the output shaft of the motor 3 on the disc 8 with an upwardly protruding edge is provided with a rotating grinding disc 7, and a mechanical disc 8 is arranged next to the upwardly protruding disc 8. Fixture 9, an angle frame 11 is also provided beside the upwardly protruding disc 8, an angle device 10 is provided on the angle frame 11, a flexible gasket 4 is provided between the motor 3 and the bottom of the workbench 5, and the workbench 5 is placed on the gear T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com