Wire drawing process based on plastic surface

A wire drawing and process technology, which is applied in the field of wire drawing process based on plastic surface, can solve the problems that the electroplating layer is easily oxidized, the effect cannot be achieved, and the product yield is low, so as to improve the wire drawing effect and aesthetics, prevent oxidation, and solve the problem of The effect of color differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0014] The most critical idea of the present invention is: spray UV ink on the electroplating layer area of the product after electroplating treatment, the ink can effectively block the oxidation of the electroplating layer, solve the problem of color difference caused by oxidation on the surface of the electroplating layer, and improve the drawing effect and aesthetics .

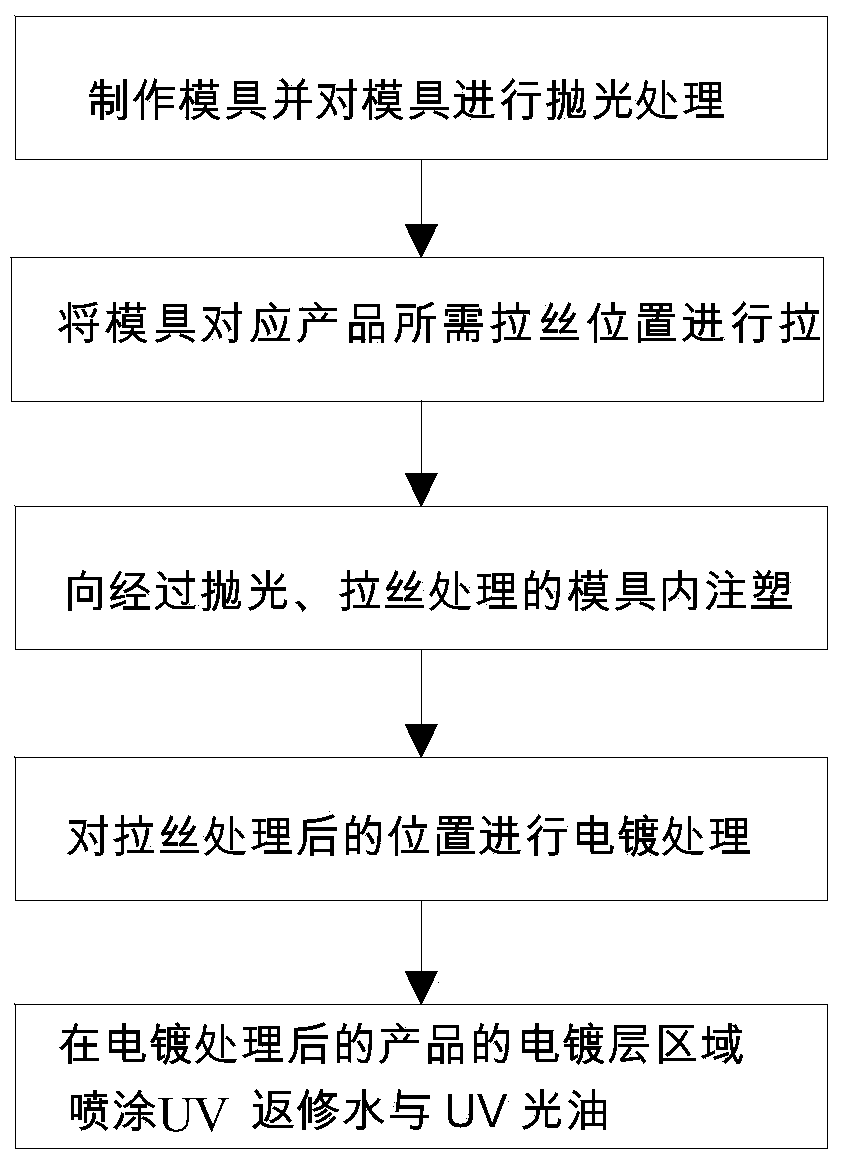

[0015] see figure 1 , this embodiment is based on the wire drawing process on the plastic surface, including the following steps:

[0016] Making molds and polishing them;

[0017] Carry out wire drawing treatment on the corresponding mold position for the required wire drawing effect on the surface of the product;

[0018] Injection molding into polished and bru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com