Liquefied natural gas pump lifting device

A technology of liquefied natural gas and rotating devices, which is applied in cranes, transportation and packaging, load suspension components, etc., can solve the problems of limited rotating range, larger devices as a whole, and increased costs, so as to achieve sufficient safety and light weight , the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Hereinafter, modes for implementing the present invention will be described with reference to the drawings.

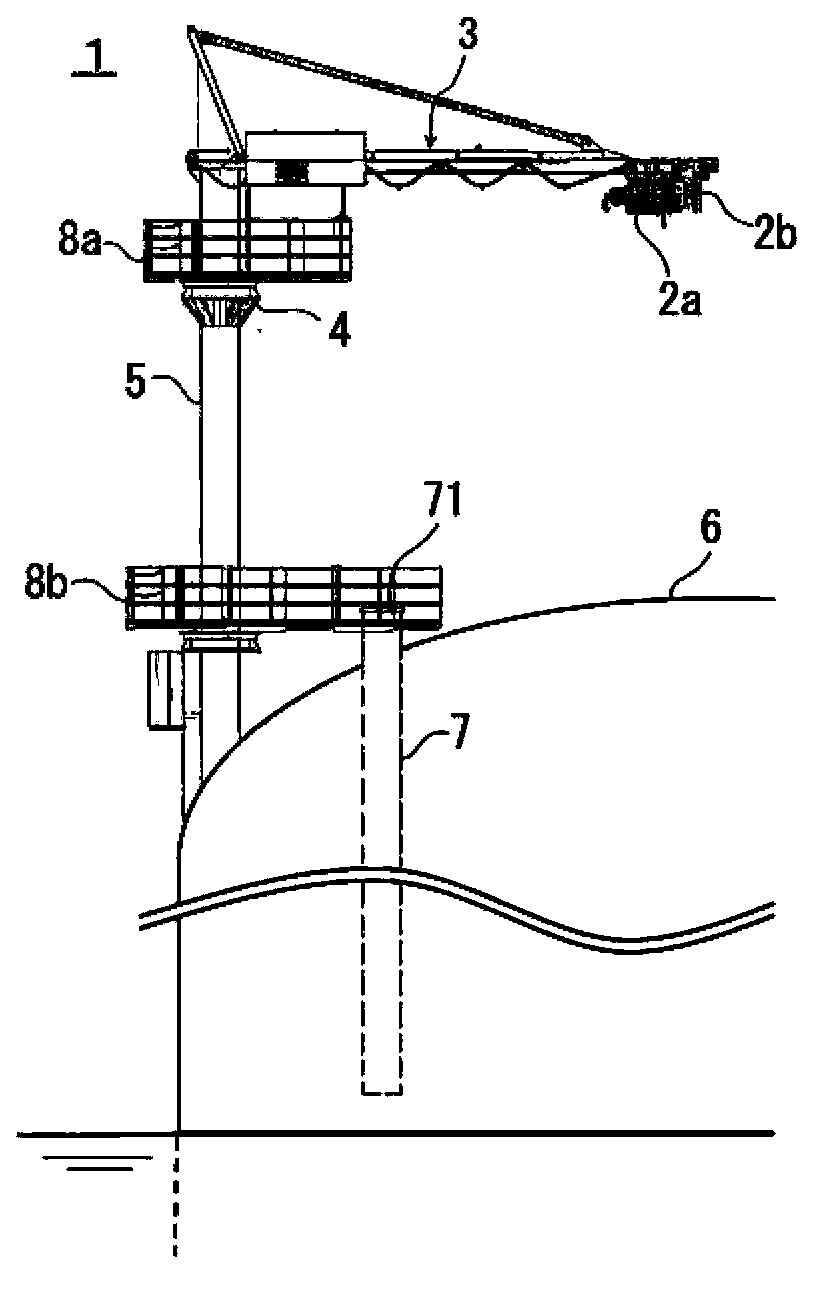

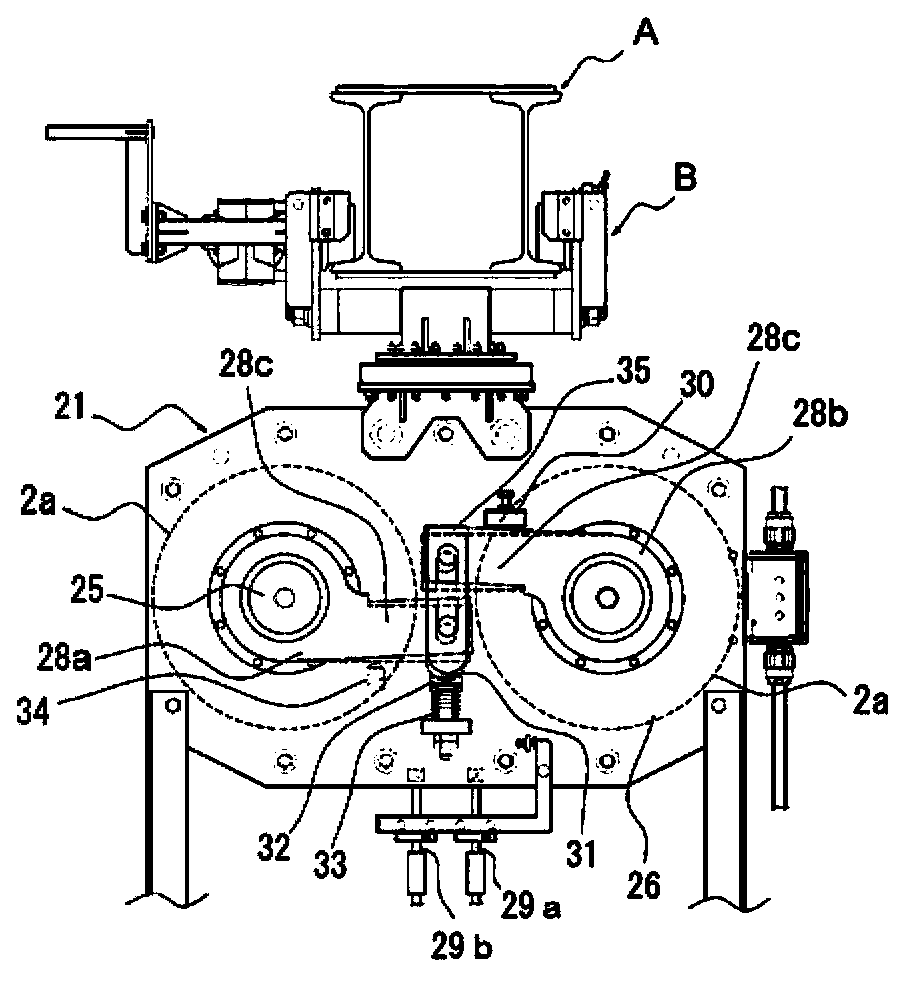

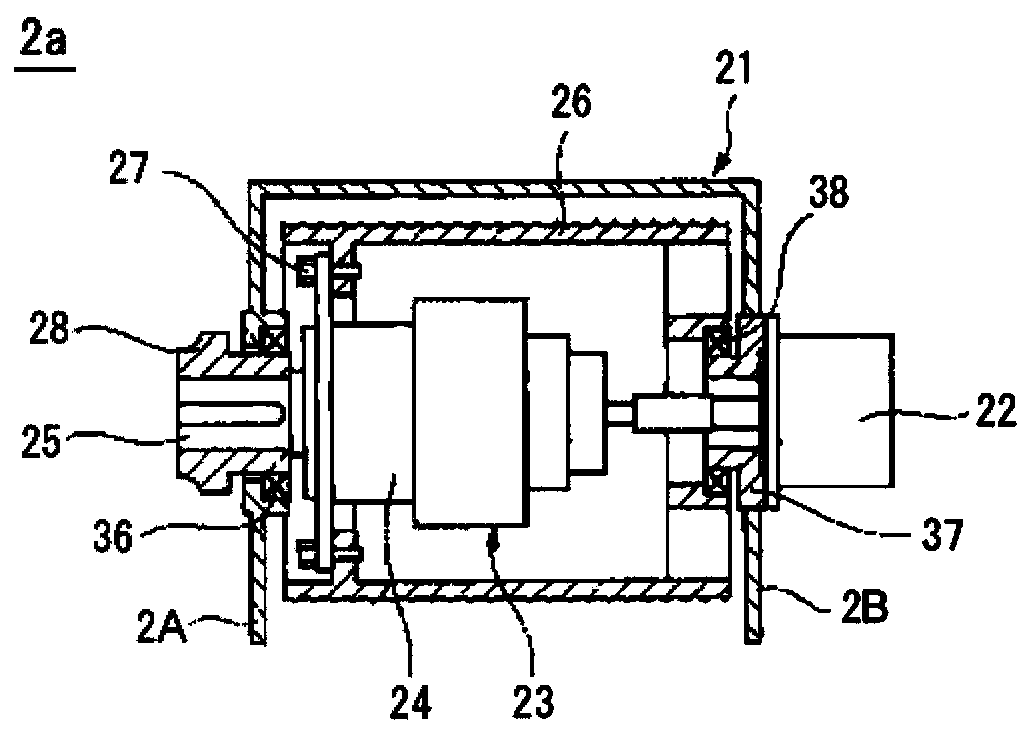

[0061] figure 1 It shows a preferred embodiment of the LNG pump lifting device 1 according to the present invention, which is arranged on the upper part or the side part of the LNG storage tank 6 installed on the ground or semi-underground, and its structure is such that the pillar 5 is vertically arranged, and above the pillar 5 The rotating device 4 is arranged, and the cantilever 3 extending from the upper end on the axis of the support 5 is installed in a direction substantially parallel to the table surface 8a provided on the upper side of the rotating device 4. The cantilever 3 is rotated by the upper part of the support 5. The device 4 is arranged rotatably at the center.

[0062] In addition, the structure is such that an elevator 2a and an elevator 2b that can move along the boom 3 are arranged, and near the front end in the center direction of the LN...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com