Hydrolysis-resistant aliphatic polyester resin composition and preparation method thereof

A polyester resin and aliphatic technology, applied in the field of hydrolysis-resistant aliphatic polyester resin composition and its preparation, can solve the problems of serious yellowing of products, harmful to human body, increase in melt viscosity, etc., and achieve excellent hydrolysis-resistant performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

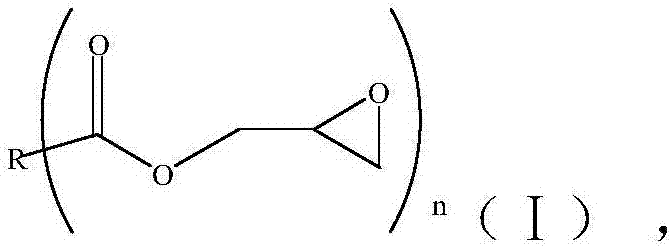

Method used

Image

Examples

Embodiment 1

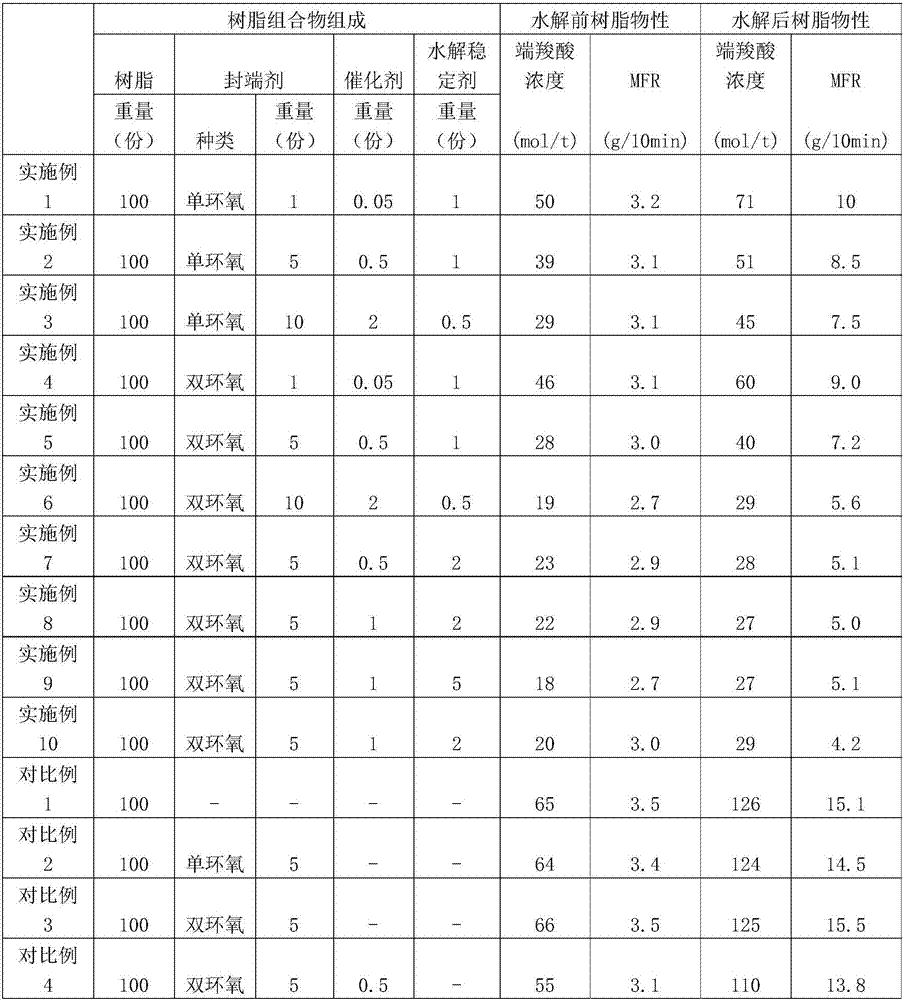

[0042] 100 parts of polyester resin, 1 part of monoepoxy end-capping agent, 0.05 part of end-capping catalyst and 1 part of hydrolysis stabilizer are dry-blended uniformly, melt-blended by a twin-screw extruder, and extruded to obtain blended chips. The feed inlet temperature of the extruder was set at 180°C, the rest of the blending temperature was set at 210°C, and the screw speed was set at 300 rpm. The changes in carboxyl group concentration and MFR at the end of the obtained resin before and after hydrolysis were analyzed. The results are shown in Table 1.

Embodiment 2

[0044] 100 parts of polyester resin, 5 parts of mono-epoxy end-capping agent, 0.5 parts of end-capping catalyst and 1 part of hydrolysis stabilizer are dry-blended uniformly, melt-blended by twin-screw extruder, and extruded to obtain blended chips. The feed inlet temperature of the extruder was set at 180°C, the rest of the blending temperature was set at 210°C, and the screw speed was set at 300 rpm. The changes in carboxyl group concentration and MFR at the end of the obtained resin before and after hydrolysis were analyzed. The results are shown in Table 1.

Embodiment 3

[0046] 100 parts of polyester resin, 10 parts of monoepoxy end-capping agent, 2 parts of end-capping catalyst and 0.5 part of hydrolysis stabilizer are dry-blended uniformly, melt-blended by twin-screw extruder, and extruded to obtain blended chips. The feed inlet temperature of the extruder was set at 180°C, the rest of the blending temperature was set at 210°C, and the screw speed was set at 300 rpm. The changes in carboxyl group concentration and MFR at the end of the obtained resin before and after hydrolysis were analyzed. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com