Phosphorus ore underground mining method

A mining method and phosphate rock technology, applied in underground mining, surface mining, special mining, etc., can solve the problems of high support cost, large dilution rate and loss rate, complex mining process, etc., and achieve support and filling costs Low, high degree of mechanical work, the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with an embodiment of a stope at the mouth of No. 2 Jinning Phosphate Mine of Yunnan Phosphate Group Co., Ltd., but is not limited to the embodiment.

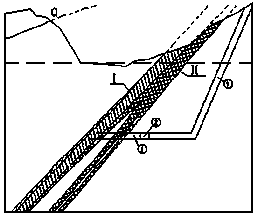

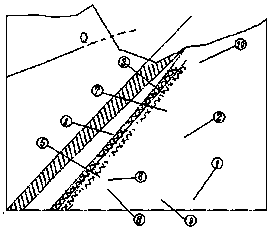

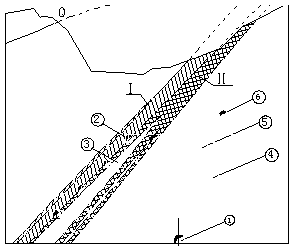

[0026] The basic situation of the No. 2 pithead stope: the inclination angle is 36°-52°, with an average of 40°, the width along the dip is 20-30m, the vertical height is 50m, and the original buried depth is about 50-200m. The grade I grade ore is located in the upper part of the ore seam, with a vertical thickness of 4.80-7.00m; the grade II grade ore is mainly located in the middle of the ore seam, in the form of a branch compound or interbedded with the grade III grade ore, and partially contains intercalated stone lenses. The upper wall ②+③ layer ore (grade Ⅰ+Ⅱ grade) is mined, the average horizontal thickness of the ore layer is 8.9m, and the average dip angle is 40°; °. The thickness of the interlayer (mainly grade Ⅲ grade) between the upper and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com