A constant velocity drive shaft of an automobile

A constant-speed drive shaft and automobile technology, applied in the field of high-speed drive shafts and automobile transmission system drive shafts, can solve problems such as deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

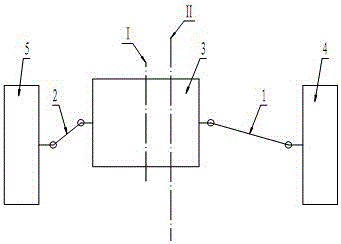

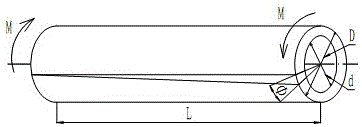

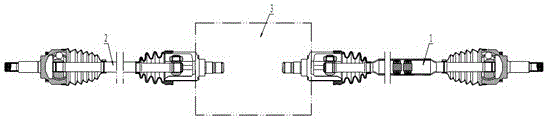

[0023] see image 3 , Figure 4 , Figure 7 , the present invention includes a left half shaft 2 and a right half shaft 1, wherein the left end of the left half shaft is assembled with the left side wheel 5 through the left half shaft fixed joint 1-3, and the right end of the left half shaft is connected with the power through the left half shaft moving joint 1-2 The left half-shaft gear of the differential in the transmission device 3 is assembled, the left end of the right half-shaft is assembled with the right half-shaft gear of the differential in the power transmission device 3 through the right half-shaft moving joint 1-2, and the right end of the right half-shaft passes through The right half shaft fixed section 1-3 is assembled with the right wheel 4, the right half shaft 1 is a hollow shaft tube structure, the left half shaft is a solid rod shaft structure, and the right half shaft hollow shaft tube 1-1 has a length of X , the length of the left half-axis solid rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com